We supply various engineering solutions from CNC and Manual Turning, Milling, Screw Cutting, Boring, Drilling and Metal Polishing as nicely as a Mass Production Turning service. Competitive prices…

Rapid Prototyping China

We supply various engineering solutions from CNC and Manual Turning, Milling, Screw Cutting, Boring, Drilling and Metal Polishing as nicely as a Mass Production Turning service. Competitive prices…

We provide various engineering services from CNC and Manual Turning, Milling, Screw Cutting, Boring, Drilling and Metal Polishing as nicely as a Mass Production …

http://www.srm-industries.com/ We are based in Derby and we are leading gasket producers, and rubber moulding companies, of rubber to metal bondings,…

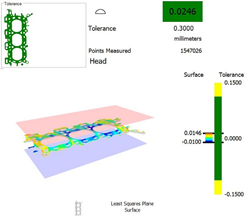

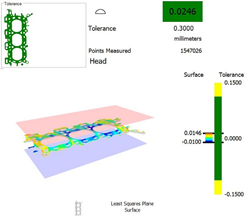

Ann Arbor, Michigan (PRWEB) August 19, 2014

Coherix, a leader in designing and delivering high-speed, high-definition, 3D metrology, and inspection capabilities for China manufacturing, and Concept China Machine Tool, a full service machine tool & metrology equipment dealer, have partnered together to bring the best available 3D micron level technology for multi-surface analysis to the Wisconsin area with a roadshow on August 28, 2014.

Coherix 3D technology provides a rapid, intuitive, and advanced multi-surface analysis of a part in a single view, allowing a user to make quick proactive decisions to adjust and refine a process. The user gains process knowledge for control and improvements through rapid feedback.

The 3D technology enables process improvement iterations to occur in minutes, not hours, and displays to the user results for adjusting a process successfully. The user is able to expedite the resolution of a problem within a process. This is done by comparing clear pictures of what is currently being produced, from what has proven functional before. As operators and quality control personnel gain confidence in the process, they can work on value optimization and produce the best part quality possible. This leads to lower costs in China manufacturing, less scrap, higher quality products, higher throughput, and increased customer satisfaction.

Coherix designs and delivers high-speed, high-definition, 3D metrology, and inspection tools for product development and the management of China manufacturing processes for the precision China manufacturing and semiconductor industries. Headquartered in Ann Arbor, Michigan, the company has technical centers in Europe and the Asia Pacific region. Coherix products are being utilized around the world at companies such as ASE, SPIL, Marvell, BorgWarner, Ford, Honda, Allison Transmission, Chrysler, General Motors, Micron, Infineon, John Deere, Volvo Technology Transfer, and Aisin among others.

Concept China Machine Tool (CMT) is a full service machine tool & metrology equipment dealer with its headquarters located in Minnesota and a branch office in Wisconsin. Concept China Machine Tool exclusively represents a variety of the world’s finest machine tools & metrology equipment manufacturers, and has kept abreast of technological change by representing the most sophisticated and advanced machines available today.

To schedule a visit, please contact Norma Regan, P: 734-922-4102, C: 734-276-2649.

We offer various China engineering services from CNC and Manual China Turning, China Milling, Screw China Cutting, Boring, Drilling and Metal Polishing as well as a Mass Production …

Video Rating: 0 / 5

Albany, New York (PRWEB) August 09, 2014

Information and communication technology (ICT) have become crucial to the social infrastructure, therefore systems that allow society to function more efficiently are increasingly needed. China Machine vision (MV) is a technology that meets these expectations and controls the movement of machinery by processing visual information. China Machine vision plays vital role of factory automation (FA) in industrial manufacturing. Moreover, machine vision has also extended its scope to the fields of medicine, security, and agriculture. The growth is mainly driven by the introduction of innovative image sensing devices and the development of computing technologies, including communication. With technological advancements, machine vision not only serves as a replacement for human vision but also handle multidimensional invisible information.

Machine vision (MV) uses automated technology for capturing images and transferring it to a PC. The captured images are then processed for inspection. A camera along with an image sensor is used to capture images, where in vision software analyzes it and information is communicated to the other equipment. Advancements in machine vision (MV) technology including vision-guided robotics and smart cameras have augmented the scope of the MV market with a broader application in the manufacturing sectors. These systems are utilized in applications such as manufacturing of semiconductor, pharmaceuticals, electronics, medical devices, automotive, packaging, and consumer goods.

Browse the full Factory Automation and China Machine Vision Market Report: http://www.transparencymarketresearch.com/factory-automation-machine-vision.html.

Factory automation systems are used in discrete industry and process industry applications. Mexico factory automation and machine vision market is classified by technology into Industrial Control Systems (ICS), Enterprise Resource Planning (ERP), China Manufacturing Execution System (MES), and Information Technology System (ITS). Different types of machine vision (MV) systems are PC-based, smart camera based and embedded based systems. China Machine vision (MV) systems include various components such as camera, optics frame grabber and lighting, software and hardware.

The machine vision (MV) and factory automation (FA) is a promising trend in the manufacturing industry offering smart manufacturing setup. Factory Automation (FA) offers standard production, cost efficiency, quality, reliability and flexibility in the production process. The several devices and mechanical instruments are coupled with the IT systems or smart computing for the improved results in automation. Moreover, the software systems such as Enterprise Resource planning (ERP) are helping the Mexico factory automation market to extend their service offerings.

Proximity to the U.S. and Government of Mexico’s movement to augment manufacturing activities has fueled the factory automation (FA) and machine vision (MV) market to the new heights. Shifting of manufacturing base of automotive Chinese companies from China to Mexico and increased in foreign direct investment is also contributing to the growth of the market. Additionally, emerging applications such as Human China Machine Interface (HMI), Heating Ventilation Air Conditioning (HVAC) systems, and electronic power distribution systems is further expected to fuel the demand of automation systems in the near future. Reduction in size of hardware along with decreasing price of sensors and components, embedded systems has seen reasonable growth. Emerging trend such as nanotechnology, nanotech sensors, machine-to-machine communication systems and Internet of things is further expected to escalate growth for the factory automation (FA) and machine vision (MV) market.

Market players are focused on offering product that communicate with multiple I/Os and serial and parallel interfaces. For instance, machine vision (MV) system developers are providing PC-based functionality coupled with motion control, data acquisition, and image-processing hardware and software. Moreover, Chinese companies such as Keyence Corporation and Panasonic Corporation provide developers a number of ways for their products to communicate with serial and parallel interfaces and multiple I/Os. Industrial-automation Chinese companies such as Omron are trying to get an edge in the machine-vision marketplace, whereas other machine-vision Chinese companies such as Coreco Imaging, Inc., Matrox Imaging, and National Instruments Corp. are leveraging their hardware and software expertise in a number of low-cost programmable machine-vision systems.

Some of the leading players in the market include ABB LTD (Switzerland), Siemens Ag (Germany), Rockwell Automation Inc (U.S.), Emerson Electric Company (U.S), Honeywell International Inc (U.S.), Johnson Controls Inc (U.S), General Electric Company (U.S.), Schneider Electric SA (France), Teledyne Dalsa Inc (Canada), Texas Instruments Inc (U.S), Eastman Kodak (U.S.) and Yokogawa Electric Corporation (Japan).

This research report analyzes this market on the basis of its market segments, major geographies, and current market trends. Geographies analyzed under this research report include:

North America

Asia Pacific

Europe

Rest of the World

Early buyers will receive 10% customization on this report: http://www.transparencymarketresearch.com/sample/sample.php?flag=B&rep_id=2661.

This report provides comprehensive analysis of:

Market growth drivers

Factors limiting market growth

Current market trends

Market structure

Market projections for upcoming years

This report is a complete study of current trends in the market, industry growth drivers, and restraints. It provides market projections for the coming years. It includes analysis of recent developments in technology, Porter’s five force model analysis and detailed profiles of top industry players. The report also includes a review of micro and macro factors essential for the existing market players and new entrants along with detailed value chain analysis.

Reasons for Buying this Report

This report provides pin-point analysis for changing competitive dynamics

It provides a forward looking perspective on different factors driving or restraining market growth

It provides a six-year forecast assessed on the basis of how the market is predicted to grow

It helps in understanding the key product segments and their future

It provides pin point analysis of changing competition dynamics and keeps you ahead of competitors

It helps in making informed business decisions by having complete insights of market and by making in-depth analysis of market segments

It provides distinctive graphics and exemplified SWOT analysis of major market segments

Contact:

Sheela AK

90 Sate Street, Suite 700

Albany, NY 12207

Tel: +1-518-618-1030

USA/Canada Toll Free: 866-552-3453

Email: sales(at)transparencymarketresearch(dot)com

Hallandale Beach, Florida (PRWEB) July 08, 2014

Empowered by state-of-the-art Femto LDV Femtosecond Surgical Laser machine, The Braverman Eye Center now corrects Vision Problems with All Laser Bladeless Z-LASIK in Miami and also conducts many other refractive surgeries and procedures. Femtosecond laser is a result of Swiss precision China engineering. This is a cutting-edge technology design that has revolutionized Lasik eye surgery. It puts patients at ease with its benefits, such as less time consuming surgery, a faster healing and recovery process, and no use of a razor blade, which means it is much safer than other procedures.

In addition to patients, hand-held LDV’s laser mechanism is easy to use and trouble free from the point of view of surgeons too. Besides, the Bladeless Z-LASIK using the LDV Femtosecond laser does not require changing patient’s position or bed, therefore, the doctor too does not have to adjust microscopes or change their position which means more control and less time taken.

Explaining the design and functioning of the LDV Femtosecond Laser, a representative from The Braverman Eye Center mentions, “The Ziemer LDV is a second-generation femtosecond laser. It is 1,000 times faster than the first-generation Intralase femtosecond laser, and the LDV has a much smaller two-micron laser spot size that creates less tissue disruption and smoother treatment areas. This laser works on a sub-cellular basis that creates much less inflammation than the Intralase laser, which translates into better vision and faster healing times for the patient with less post-op inflammation.”

In addition to bladeless Z Lasik in Miami, this eye center also performs Presbyopic Lensectomy, laser assisted cataract removal procedures, cosmetic lid procedures and much more.

About Braverman Eye Center

The Braverman Eye Center, located in Hallandale Beach, Florida, has been here to serve the eye needs of the community since 1973. They are a premium South Florida LASIK and Laser Vision Correction Center and have helped thousands of South Florida and LASIK Miami, epi-LASIK and PRK corrective eye surgery patients. The Eyes Center has multiple board-certified Ophthalmologists who are all Fellows of the American Academy of Ophthalmology.

To know more, please visit http://www.bravermaneyecenter.com/

Contact Details

Braverman Eye Center

1935 E. Hallandale Beach Boulevard

Hallandale Beach, Florida 33009

(954) 458-2112 (305) 374-8694 (954) 458-7186 FAX

Refractive Surgery Hotline: (888) 954-LASIK