Some cool precision engineering photos:

Checking a vertical mill

Image by tudedude

Using a dial gauge indicator to check a vertical mill for accuracy

Rapid Prototyping China

Some cool precision engineering photos:

Checking a vertical mill

Image by tudedude

Using a dial gauge indicator to check a vertical mill for accuracy

Lumber Liquidators Launches New Sustainability Web site

As component of its ongoing vertical integration strategy that is placing logging, milling and retail operations geographically closer to its operations, more wood is getting sourced from North America, which in turn, will translate into a lot more North American …

Read much more on PR Newswire (press release)

Machining center reliability gives key to profitability at Holland Molds

In 2012, Holland replaced its earlier gear with a new Makino F5 vertical machining center. The investment offered the firm with twice the spindle speed at 20,000 rpm, improved positioning accuracy and higher tooling choices. Collectively, these …

Study much more on Canadian Metalworking

secondhand to initial rate: 10 upcycling shops worth checking out

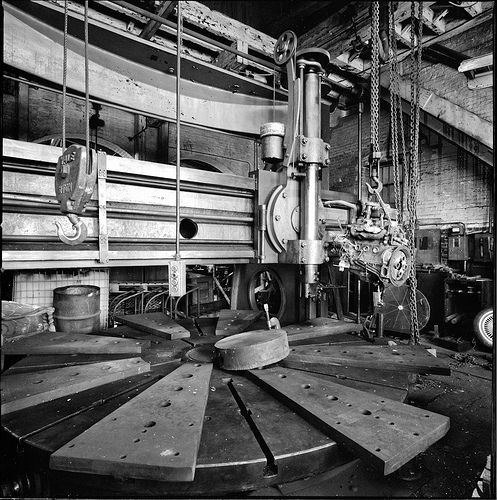

An 80,000-pound press brake keeps watch more than rows of pumps, milling machines and saws. A enormous turret lathe, manufactured in the early 1900's just eight miles away at the Warner & Swasey factory on … "When you go to HGR and just appear at these …

Read much more on freshwatercleveland

Verify out these vertical milling machine photos:

Bridgeport milling machine (constructed in 1948)

Image by Darron Birgenheier

Bridgeports constructed America!

Checking a vertical mill

Image by tudedude

Utilizing a dial gauge indicator to verify a vertical mill for accuracy

Verify out these vertical milling pictures:

Los Molinos, Ronda, Spain

Image by Swedish National Heritage Board

The area "Los Molinos" (The Mills), viewed from the New Bridge, Puente Nuevo, in the town Ronda in the Malaga province in Andalusia. On leading of the image is the gateway "Arco del Cristo" or "Puerta de los Molinos".

Området "Los Molinos" sett från Nya bron i staden Ronda i provinsen Malaga, Spanien. Högst upp på bilden syns porten "Arco del Cristo" eller "Puerta de los Molinos".

Location: Ronda, Málaga, Andalucía, Spain

Photograph by: Carl Curman

Date: 1878

Format: Cyanotype

Persistent URL: www.kms.raa.se/cocoon/bild/show-image.html?id=16001000211904

Study much more about the photo database (in english): www.kms.raa.se/cocoon/bild/about.html

Image by uʌ

Charlotte, NC (PRWEB) September 25, 2014

Okuma introduced its new V760EX vertical lathe, an update to the well-known V60R model at IMTS 2014. This new version offers a bigger operate envelope in the very same footprint, permitting for an further 110mm in workpiece height and an added 150mm maximum turning diameter. It gives stable, higher-precision cutting in a little footprint and is an excellent platform for machining thin and odd-shaped function pieces, and is properly suited for the oil and gas and aerospace industries.

The V760EX vertical lathe has effective cutting capabilities, a class major functioning range, and exceptional ergonomics. The box way method and rock strong base and column give a very reliable, hugely rigid structure. The headstock has flange building such as precision, hand-scraped mounting surfaces. This minimizes the effects of thermal deformation and vibration, guaranteeing stable, precise cutting.

This machine’s ergonomic design and style consists of straightforward access to the chuck and a front-skirt operation panel, delivering comfort for up-close jobs.

Key Specs of the V760EX Vertical Lathe

Max Turning Diameter, mm (in) Ø 760 (Ø )

Spindle Nose Sort, JIS A2-11

Speed Range, min⁻¹ 20~two,000

Energy 30 min, kW (hp) 30 (40)

Energy cont., kW (hp) 22 (30)

Fast Traverse (X/Z), m/min (ipm) 24/24 (945/945)

For much more details on Okuma’s V760EX visit http://www.okuma.com/v760ex.

About Okuma America Corporation

Okuma America Corporation is the U.S.-primarily based sales and service affiliate of Okuma Corporation, a planet leader in CNC (computer numeric handle) machine tools, founded in 1898 in Nagoya, Japan. The business is the industry’s only single-source provider, with the CNC machine, drive, motors, encoders, spindle and CNC manage all manufactured by Okuma. Okuma’s innovative and reliable technology, paired with comprehensive, localized service protection, makes it possible for users to run continuously with self-assurance – maximizing profitability. Along with its industry-leading distribution network (largest in the Americas), and Partners in THINC, Okuma facilitates top quality, productivity and efficiency, empowering the buyer and enabling competitive advantage in today’s demanding manufacturing environment. For much more details, check out http://www.okuma.com or stick to us on Facebook or Twitter @OkumaAmerica.

About Partners in THINC

Partners in THINC is a collaboration network of more than 40 market leaders who come collectively to resolve difficulties and explore new productivity concepts for real-world producers. With the open architecture, Pc-based THINC®-OSP handle as its nucleus, Partners in THINC brings specialized gear, expertise and a commitment to provide the very best achievable integrated solutions to the end-user. For far more information, check out http://www.okuma.com/partners-in-thinc.

###

CNC lathe Puma V300 forging components machining.

Video Rating: / five

www.netrin.com.tw.

Video Rating: / 5

This is our big vertical mill machining the face of a large plate with a massive 8″ finish mill… Not numerous machines could even hold that tool! Precision Prototyp…

Video Rating: / five

Fast Machining specializes in fast turn prototype machining, quoting and manufacturing from 3D CAD information – Quotes in Hours. Components in Days Get a RapidQuote a…

LM vertical roller milling machine attributes and technologies

Many types of raw material grinding equipment, from the total in the kind of point of view, can be divided into ball mill and vertical roller mill. View of the ball mill energy consumption shown critical, developing issue of upkeep and complicated, large vertical roller mill decision of a new direction.

Vertical roller mill is the cement sector, coal, electricity and other departments broadly utilised as a milling machine equipment. With a modest footprint, low energy consumption, noise, approach straightforward, compact layout, centralized pieces, drying, grinding, the powder as one particular of the advantages of a modern day cement raw material grinding device of choice. Improvement of the world’s initial vertical roller mill is the Federal German Loesche (Loesche) firm in 1925 to have a a lot more mature design and style. Via continuous development and improvement, and the most significant LM63.4, production reached 840t / h, disc diameter of six.3m, installed energy of 5600kW, the four rollers.

With the involvement of cement production line in China more and a lot more enterprises, vertical roller milling machines and other technologies in China gradually catch up with the world advanced level. At present, advanced technologies, vertical roller mill machine manufacturer Machinery Co., Ltd. Shanghai World production is also a state that LM vertical roller milling machine, while the Shanghai World states in the production process far more interest to client feedback and item overall performance.

Right after a extended-term improvement, the Shanghai Planet State Machinery Co., Ltd. Consolidated other vertical roller mill gear design and style LM vertical roller mill, compared with other grinding equipment, vertical roller mill has the following features.

1. The grinding efficiency, the use of material bed crushing squeeze principle, the material in the milling machine by rolling, shear, effect impact. Mill pulverized material can flow out in time to stay away from more than-grinding, the material in the mill residence time is usually 2-4rain, ball mill grinding efficiency is 165%, power consumption can be lowered about 30%.

two. Drying efficiency, hot air jet from the annular slit men and women, higher wind speed, a large section of the mill ventilation, the resistance is little, kiln preheater using waste gas can be dried material moisture content material of eight%, if water can be drying stove 15% to 20% of the material.

three. Grinding particle size had been huge, normally up to five% of roller diameter, particle size up to large weary 150 ~ 200mm, gear technologies, superior efficiency, single yield, higher price of equipment operation, metal wear and tear than the reduce ball .

four. Grinding materials, adaptability, can be utilised for grinding a variety of raw fuel, such as limestone, sandstone (Si02> 90%), coal, cement clinker, blast furnace slag. Regardless of grindability, how diverse abrasive, by mill and affordable operation of internal restructuring, can make diverse fineness, diverse specific surface location of the certified products.

5. The approach is easy, compact layout, routine upkeep costs low, open-air settings, investment in infrastructure is about 70% of the ball mill.

six. The all round efficiency sealed, dust, low noise and environmental advantages.

7. Item top quality control rapidly, adjust the solution versatile and simple to accomplish operational intelligence, automation.

8. The disadvantage is not appropriate for vertical roller mill grinding hard and abrasive materials, a big, worn parts costly than the ball, but they replaced the ball mill, elevator, separator and other equipment compared to the total quantity of upkeep is still appears to sustain a simple, easy and modest quantity of operate.

If you want to know a lot more about other grinding mill and crusher, please get in touch with me.

Bridgeport EZ-Trak three-Axes CNC Vertical Milling Machine Manufacturer: Bridgeport Model: EZ-Trak S/N: BR-278447E Year: 2002 Specifications: X-Axis Travel 36″ (…

Locate A lot more Vertical Milling Articles

1HP CINCINNATI VERTICAL MILLING MACHINE Serial Quantity: 6J1V5C-96 Age: n/a Equip & Specs: Model #Tool Master 8 Spindle Speeds: 140-3800 RPM Table Size: 10″ x …

Video Rating: five / five