As the sphere of engineering is vast, so the usages of machineries are also varied. There are different specific ranges of machines which are devised for a distinct sector. On the other hand, handful of among them have got universal usages. So, the tools that support in the manufacturing processes of other tools – want to be versatile in nature.

Computer numeric controller, popularly known as CNC is capable of reading G-codes which is beneficial in preserve the machine going. The mechanical device is utilized in making metal components to be utilised in bigger machines. CNC machining can do a lot of tasks which includes spinning, bending, welding, gluing, fabricating and cutting. This type of machining is highly employed in producing Barmag parts and extrusion components.

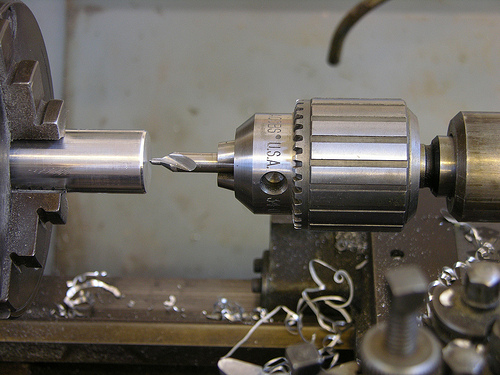

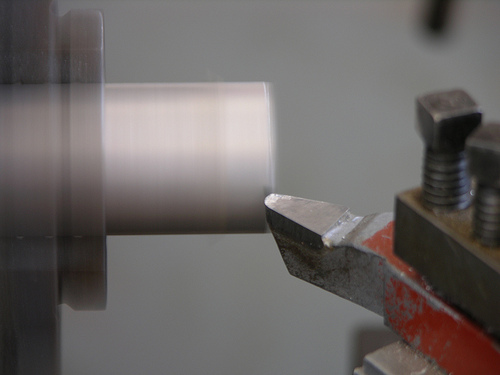

CNC turning is specially employed for drilling. The pointed and extended piece of metal in the tool rotates in higher speed which outcomes into producing whole in heavy metals. Apart from heavy metals, the tool can also be utilised in drilling wood, masonry and rock. CNC turning is also very applicable in EDM or electrical discharge machining which is utilized for giving a certain shape to a metal piece.

Surprisingly, CNC machining has got a vast business sphere when it comes to its usages. For instance, die manufacturing businesses use this machine to customize dies for pasta, macaronis and other snack items. So the changes in business have compelled the CNC turning machine manufactures to hold in thoughts all the usages the machine has got, and to design it accordingly. Customization is also an alluring option right here. If you have a business that needs such type of a tool, you must search a little on the Net and uncover out a farm that manufactures CNC machining. Make contact with and deal with the 1 which can supply you the greatest deal.

For instance, Barmag parts as nicely as extrusion components have to be made and devised depending upon the correct precision. SO if you have a customized requirement, it is advisable to go for a farm that has got large business expertise and possesses an experience of serving clientele from a cross section of the industry. Purchasing or procuring heavy equipment is a onetime investment for most of the farms, therefore, chose the tool judiciously so that it can repay you the worth you will commit on it.

About Author:

For further info on Barmag parts and Metrology please check out http://www.ppiparts.com/

Associated Cnc Engineering Articles