Saint Louis, MO (PRWEB) December 30, 2014

Beckwood Press Organization, manufacturer of advanced hydraulic press solutions and the Triform line of specialty forming presses, has expanded its Triform solution line with the addition of a 15,000 PSI Deep Draw Sheet Hydroforming press, featuring a 12” diameter maximum blank size and a 7” draw depth capacity.

The new Triform, Model 12-15-7BD, has a specific appeal to industries and operations involved with the frequent forming &amp drawing of high-strength supplies for parts which match inside the 12” diameter maximum blank size region. The 12-15-7BD supplies a lot of of the very same advantages of Triform’s current 610-20-3SC (6” x 10” maximum blank size, 20,000 PSI, 3” draw depth capacity), whilst supplying a larger forming location and higher draw depth capacity for more all round flexibility.

Healthcare device makers, for instance, who typically cold form titanium, stainless steel, inconel, hastelloy and other high-strength alloys, will locate this compact and effective Triform a welcome resolution to their manufacturing operations,” stated Beckwood’s President, Jeffrey Debus.

Beckwood’s new 12-15-7BD advantages from all of the identical technologies which have created their other Triform Deep Draw presses an sector common for higher-efficiency forming &amp drawing operations. Precision diaphragm pressure and punch position manage, combined with built-in recipe handling capability, gives considerably enhanced forming proficiency in an intuitive package. For rapidly, price-effective new part development, the 12-15-7BD features Triform’s exclusive ‘In-Sight’ feature, which allows the press to be paused and opened at any point in the forming cycle to permit for a visual inspection of the forming process. And the structure itself – which is engineered for Infinite Life – maintains its compact, flush-floor design and style, requiring no pits or unique foundations for installation.

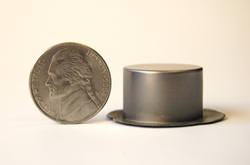

The 12-15-7BD, like all other Triform Deep Draw presses, also advantages customers in the way it makes pressure. “Beckwood’s Triform presses do not rely on oil displacement in the bladder by the punch or kind tool, to attain the programmed stress,” stated Debus. “The influence this difference can have is undoubtedly well known to numerous users of late model Cincinnati hydroforms, which all rely on displacement pressure. In other words, any size portion, from the smallest to the biggest the model can accept, can be formed in any size deep draw Triform. We have eliminated the need to have to operate a assortment of press sizes to cover the variety of parts needing to be formed,” he continued. “We’ve taken this to the intense, when creating and forming a thimble-sized cup on a press featuring a 24” maximum blank capacity with a 10” depth of draw.

About Beckwood Press Company

The Beckwood Press Business is a major hydraulic press supplier, situated in St. Louis, MO USA. They supply quality, custom hydraulic presses for practically every business &amp application, including a line of high-temperature hot forming / SPF presses for forming structural aerospace elements. Beckwood also manufactures the Triform line of Sheet Hydroforming Presses in each fluid cell and deep draw models, hydraulic ring expanders / sizers, hot joggle presses, as nicely as a line of stretch forming machines for both extrusion, sheet and major edge applications. Get the newest news from Beckwood at http://www.beckwoodpress.com/news.

Uncover Far more Precision Engineering Press Releases