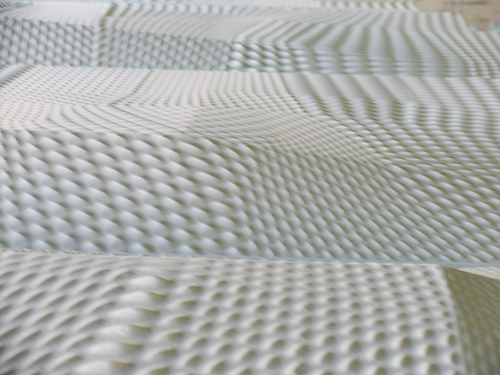

The punching and metal stamping tool comprises a driving mechanism which moves an upper tool section, having a die, towards a decrease tool section, getting a punch, to punch at least a pair of angled hooking cuts into two metal bands, such as the overlapping ends of a strap wrapped around a package. The angled hooking cuts successfully fasten the bands with each other.

The driving mechanism comprises a cam, which moves the upper tool section to a set position exactly where the upper tool section is a distance from the reduce tool section roughly equal to the thickness of the bands. The driving mechanism also comprises an eccentric shaft getting a throw which acts on the upper tool section to punch the angled hooking cuts into the bands.

Hooper and strapper devices for binding together the overlapping ends of a metal strap wrapped around a package generally comprise an upper tool having a die which moves onto a corresponding stationary decrease tool possessing a punch. The upper and lower tools act on overlapping ends of the strap to execute a punching and metal stamping operation to create at least a pair of angled hooking cuts in each of the overlapping ends as disclosed, for instance, in U.S. Pat. No. 5,029,433 to Werk.

The angled hooking cuts are such that the reduce band is “woven” or “hooked” onto the upper band to fasten with each other the overlapping ends in a known manner. The angled hooking cuts can be of any shape to permit the lower band to be “woven” or “hooked” onto the upper band, but generally the cuts comprise an angled cut positioned in between a wide reduce region and a narrow reduce area on the band. Usually, the bands are fairly biased for the duration of the punching action such that when the overlapping ends of the strap are trimmed off, the bands slide somewhat toward every single other thereby hooking with each other the projecting corners of the bands produced by the angled hooking cuts in the bands.

These prior art devices endure from a number of disadvantages. In particular, the rocking or pivoting motion of the die essential the housing to be considerably larger than the mounting block upon which the die was mounted. This resulted in an improved quantity of dust and dirt entering the housing and rising the put on of the components. In addition, these prior art devices typically utilized the interaction of a cam on a roller device to produce the pivoting or rocking motion. This arrangement resulted in a substantial amount of the forces becoming transferred by way of a hairline juncture amongst the cam and roller device. It is apparent that by having concentrations of such forces on a hairline juncture, improved wear and tear benefits.

Accordingly, it is an object of this invention to at least partially overcome the disadvantages of the prior art. Also, it is an object of this invention to supply an alternative kind of punching and metal stamping tool wherein the upper moving tool possessing the die is driven by a driving mechanism which moves the upper tool along a path substantially perpendicular to the surface of the metal bands becoming joined with each other, but keeping the needed force to impact the punching process relatively weak. It is also an object of the present invention to provide a driving mechanism possessing a double action or two step driving motion wherein a 1st setting means offers a relatively rapid movement of the upper tool section to a set position close to the reduced tool throughout the initial activation of the driving means and then a second slower but far more strong punching drive means engages to execute the punching process.

It is also an object of this invention to provide a punching and metal stamping tool wherein the upper tool is mounted on a mounting block which moves fully within an aperture of a housing such that the aperture is substantially the very same size and shape as the mounting block. This aperture can define a passageway. This prevents the entrance into the punching and metal stamping tool of dust and dirt which increases the put on of the moving, force bearing components.

Additional aspects of the invention reside in providing a punching and metal stamping tool for fastening two metal bands collectively, mentioned bands extending lengthwise in a longitudinal direction and every band having a thin side and a wide side, stated wide side having a thickness in a direction perpendicular to the longitudinal direction and defining a surface extending substantially parallel to the longitudinal direction, said tool comprising: an upper tool section and a lower tool section for fastening the metal bands with each other and adapted to receive mentioned metal bands lengthwise therebetween when mentioned upper tool section is in a 1st position a driving mechanism for moving the upper tool section towards the lower section along a path, stated driving mechanism comprising: setting indicates for moving the upper tool section towards the decrease tool section from the very first position to a set position wherein the upper tool section is a distance above the decrease tool section substantially equal to a sum of the thicknesses of the bands punching drive indicates for moving the upper tool section towards the reduce tool section to create at least one particular pair of angled hooking cuts in and along both metal bands and wherein said setting means moves said upper tool section to the set position before the punching drive signifies moves the upper tool section resulting in the angled hooking cuts.

In a nonetheless additional aspect, the present invention resides in delivering a strapping device comprising: a tensioning implies for tensioning a portion of a metal strap wrapped about a package, said strap possessing overlapping ends extending lengthwise in a longitudinal path and each end getting a thin side and a wide side, mentioned wide side possessing a thickness in a path perpendicular to the longitudinal path and defining a surface extending substantially parallel to the longitudinal path punching and metal stamping tool means for fastening stated overlapping ends.

It will be understood that, though a variety of attributes of the invention have been described with respect to one or one more of the embodiments of the invention, the different functions and embodiments of the invention may possibly be combined or used in conjunction with other characteristics and embodiments of the invention as described and illustrated herein.

Although this disclosure has described and illustrated certain preferred embodiments of the metal stamping tools invention, it is to be understood that the invention is not restricted to these specific embodiments.

xlnb.cn is a Manufacturer and suppliers of shower drain, sheet metal stamping, metal stamping, Gear parts by OEM/ODM service with diversified schemes.

Find A lot more Metal Stamping China Articles