Albany, New York (PRWEB) August 20, 2014

According to a new market report published by Transparency Market Research “Electronic Recycling (Copper, Steel, Plastic resins) Market – Global Industry Analysis, Size, Share, Growth, Trends and Forecast 2013 – 2019”, the market was valued at USD 9.84 billion in 2012, which is expected to reach USD 41.36 billion by 2019, growing at a CAGR of 23.06% from 2013 to 2019. In terms of volume, the market was 48.43 million tons in 2012 and is forecast to reach 141.05 million tons by 2019. In terms of volume, Europe was the largest recycler of e-waste and Asia Pacific is expected to be the fastest growing market for electronic recycling during the forecast period, growing at a CAGR of 22.8% from 2013 to 2019. Lack of efficient government regulations made Asia Pacific a collection point for global e-waste. Availability of abundant volume of e-waste and cheap labor is expected to drive Asia Pacific electronic recycling market.

Browse Global Electronic Recycling Market Report with full TOC: http://www.transparencymarketresearch.com/electronics-recycling-market.html.

The global electronic recycling market is expected to be driven by implementation of stringent government regulations, environment sustainability programs, and rapid industrialization. End of life management of electronic product involve refurbishment of functional components and recycling of waste scrap. Despite numerous benefits of recycling, lack of regulatory and recycling infrastructure has hampered the growth of this market. In addition, lack of consumer awareness regarding electronic recycling market and no incentive policy for consumers has restricted the growth of electronic recycling market.

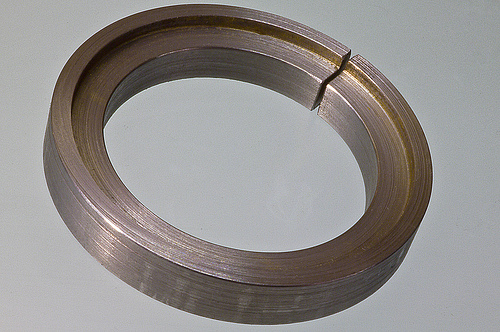

Out of all equipments being recycled, computer was the largest segment in 2012 and is forecast to maintain its dominance in future. This attributes to rapid microchip developments and decrease in average lifecycle of computers. Numerous take back events organized by leading telecom players are expected boost the electronic recycling market. For example, in 2008 Nokia started its e-waste management campaign when waste management was given little attention. Based on sources of electronic equipment commercial sector were highest contributors to recycling market in 2012. This accounts to the infrastructural developments across developing economies. Globally steel was the most recycled material from electronic scrap because steel is heavily used in electronic devices and cost fluctuations of mined steel made manufacturers adopt closed loop practice which involves using recycled steel back into China manufacturing of new products. Additionally, recycling steel is much cheaper compared to mining steel. In terms of revenue, recycled steel accounted for 33.7% of the global electronic recycling market in 2012.

Geographically, Europe dominated e-waste recycling market in 2012. This is attributed to stringent legal directives and regulations to recover recycle and reuse e-waste. In North America, around 65% of U.S. residents are governed by e-waste law. Though there is no mandatory recycling regulation in the U.S. 25 states across the U.S. have ratified several regulations that require statewide e-waste recycling. Emerging economies in Asia Pacific such as Korea, Taiwan, India, China and Japan are expected to be fastest growing for electronic recycling. This growth is majorly driven by abundance of e-waste in Asia pacific and cheap labor availability.

The global electronic recycling market is highly fragmented and contains numerous small scale players. However, Sims Metal Management hold majority of shares of electronic recycling market. Major industry participants include Eco-Tech Environmental Services Inc., AERC Recycling Solutions, American Retroworks Inc., CRT Recycling Ltd., Dlubak Glass Company, Fortune Plastic & Metal, Inc., MBA Polymers, Inc., Sims Metal Management Limited, Universal Recyclers Technologies, A2Z Group.

Related & Recently Published Reports by Transparency Market Research

Distribution Automation Market: http://www.transparencymarketresearch.com/distribution-automation-market.html

Colored PU Foams Market: http://www.transparencymarketresearch.com/colored-pu-foams-market.html

The market has been segmented as follows:

Electronic Recycling Market, by type of processed material

Copper

Steel

Plastic resins

Polycarbonate

Acrylonitrile butadiene styrene (ABS)

Acrylonitrile butadiene styrene (ABS)

High impact polystyrene (HIPS)

Polystyrene –

Others

Others (zinc, tin, nickel, lead, aluminum, gold, silver, so on)

Electronic Recycling Market, by type of processed material used as stock

Copper

Steel

Plastic resins

Polycarbonate

Acrylonitrile butadiene styrene (ABS)

Acrylonitrile butadiene styrene (ABS)

High impact polystyrene (HIPS)

Polystyrene –

Others

Others (zinc, tin, nickel, lead, aluminum, gold, silver, so on)

Get report sample PDF copy from here: http://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=601.

Electronic Recycling Market, by type of equipment processed

Computers

Telecom

Industrial

Consumer

Others

Electronic Recycling Market, by source of equipment

Consumers/residential

Manufacturers/Industry users

Government agencies

Schools/universities

Commercial

Electronic Recycling Market, by geography

North America

Europe

Asia Pacific

RoW

Contact:

Sheela AK

90 Sate Street, Suite 700

Albany, NY 12207

Tel: +1-518-618-1030

USA/Canada Toll Free: 866-552-3453

Email: sales(at)transparencymarketresearch(dot)com