Verify out these stamping components china photos:

Image from web page 95 of “Sunset” (1898)

Image by Internet Archive Book Photos

Identifier: sunset74jansout

Title: Sunset

Year: 1898 (1890s)

Authors: Southern Pacific Company. Passenger Division

Subjects:

Publisher: [San Francisco, Calif. : Passenger Dept., Southern Pacific Co.] Menlo Park, CA : Sunset Publishing Corporation

Contributing Library: Web Archive

Digitizing Sponsor: Internet Archive

View Book Page: Book Viewer

About This Book: Catalog Entry

View All Pictures: All Pictures From Book

Click here to view book online to see this illustration in context in a browseable on the web version of this book.

Text Appearing Before Image:

to the jaded traveler, thisdesert oasis, and a single of the grandestplaces we know of for a winter holi-day. Do you want a booklet on PalmSprings resorts? Send along a three-cent stamp then, please. Although in theSouth strategy to see all of the country.Create us for the Official Tourist Guideto Southern California, What to Doand See, and What It Will Expense. Zion NationalPark Open Travel Editor, Sunset Magazine: We are spending the winter in southern Cali-fornia. Among the trips we had planned whilethere is the 1 to Boulder Dam. We are wonder-ing ij it would he feasible to go on to Zion Na-tional Park white we are so close to? We understandit closes throughout the winter, but believed we mightbe able to see at least a component of it by driiing inand out the same day. Have you any folders onZion?—T. G., Portland, Oregon. Heretofore Zion National Park hasusually been closed throughout the winter—that is, all accommodations in thepark have been closed. Late in the fallof 1934, nonetheless, it was decided to TRAVEL

Text Appearing Right after Image:

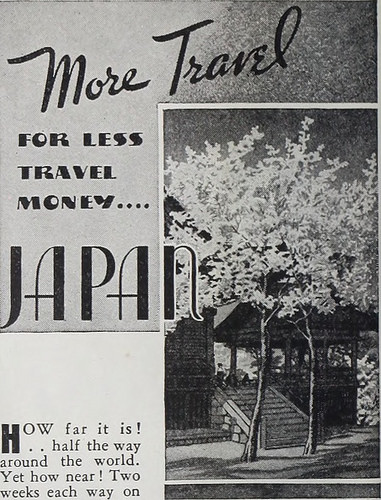

HOW far it is!. . half the wayaround the world.Yet how near ! Twoweeks every single way onswift, modern day lin-ers—at the lowest fare in the globe thinking about serv-ice and the distance traveled. Let your self six |weeks and you can make the trip with ease. Atcost as low as practically any six weeks trip ! The |yen exchange, keep in mind, is strongly in your favor,not against you. Don’t forget too the all-inclusiveitineraries supplied at the lowest feasible expense by theJapan Tourist Bureau—trips that show you the greatcities, shrines and scenic miracles of Nippon in aweek, two weeks or more, as you decide on. jnpnn tourist burehu Address your tourist agent or the Japan TouristBureau, c/o Japanese Govt Railways, iil FifthAve., N. Y. C, or Chamber of CommerceBldg., llil South Broadway, Los Angeles, Cat.,or c/o .Nippon Yusen Kaisha, 2i Broadway,N. Y. C. Please address Dept. S in every single case tofacilitate prompt reply. TOURING MAPS Did you get your copy of the UnitedStates Touring Map as otiered last monthlor a

Note About Images

Please note that these photos are extracted from scanned web page photos that may possibly have been digitally enhanced for readability – coloration and look of these illustrations might not completely resemble the original work.

220809 Waratah

Image by Nico Nelson

The floral emblem of our state of New South Wales in Australia. Telopea speciosissima.

****See beneath from the Australian Capital Botanic Gardens Website:****

The generic name Telopea is derived from the Greek ‘telopos’, meaning ‘seen from afar’, and refers to the fantastic distance from which the crimson flowers are discernible. The certain name speciosissima is the superlative of the Latin adjective ‘speciosus’, meaning ‘beautiful’ or ‘handsome’. ‘Waratah’, the Aboriginal name for the species, was adopted by early settlers at Port Jackson.

Telopea is an eastern Australian genus of 4 species. Two are confined to New South Wales, one to Tasmania and 1 extends from eastern Victoria into New South Wales. Telopea belongs to the family members, Proteaceae, which is predominantly Australian and southern African in distribution and involves genera such as Grevillea, Banksia, Macadamia and Hakea. Protea cynaroides, King Protea, is the official floral emblem of the Republic of South Africa.

The Waratah is a stout, erect shrub which could grow to 4 metres. The dark green leathery leaves, 13-25 cm in length, are arranged alternately and have a tendency to be coarsely toothed. The flowers are grouped in rounded heads 7 to ten cm in diameter surrounded by crimson bracts, about five to 7 cm long. It flowers from September to November and nectar-searching for birds act as pollinators. Big winged seeds are released when the brown leathery pods split along one particular side.

Telopea speciosissima distribution mapThe species is fairly widespread on the central coast and adjoining mountains of New South Wales, occurring from the Gibraltar Variety, north of Sydney, to Conjola in the south. It grows mostly in the shrub understorey in open forest developed on sandstone and adjoining volcanic formations, from sea level to above 1000 metres in the Blue Mountains. Soils inside its variety have a tendency to be sandy and low in plant nutrients. Rainfall is moderately higher. Waratah plants resist destruction by bushfires, a natural element of their habitat, by regenerating from the rootstock. Flowering recommences two years right after a moderate fire.

The Waratah is a spectacular garden topic in appropriate soil and climate it flowers prolifically and tends to be long-lived. Failures can generally be attributed to the effects of unsuitable soil situations, aspect or climate. Seeds must be sown in a coarse sandy medium and quickly right after germination the seedlings ought to be transplanted into person pots of related soil. Fresh seeds germinate readily but the seedlings are prone to the fungal illness, ‘damping off’, which might be lowered by exposing the seedlings to complete light, except for the shading needed soon after transplanting. Propagation by cuttings is also attainable. In the garden, plants ought to be grown in lightly shaded to sunny positions in deep, nicely drained soil. They need to be properly watered till fully established but waterlogging should be avoided.

The Waratah responds effectively to pruning which encourages flowering the following year, and overcomes the organic tendency of the shrub to assume a straggly shape. Some pruning is achieved by cutting flowers for decoration. It is a spectacular cut flower and lasts well in water.

Flowers are typically crimson, but a rare creamy white kind, Telopea ‘Wirrimbirra White’, has been cultivated effectively as a horticultural curiosity. Manipulated hybrids of T. speciosissima have been created combining the grandeur of its flowers with the greater frost tolerance of other Telopea species. Hybrids between T. speciosissima and the Braidwood Waratah, T. mongaensis, have smaller sized flowers but are typically far more floriferous with a compact shape and appealing foliage. 1 of these hybrids is the registered cultivar, Telopea ‘Braidwood Brilliant’, a spectacular garden plant developed at the Australian National Botanic Gardens.

The Waratah occurs naturally in at least ten national parks in the geological formation, know as the Sydney Basin. Brisbane Water, Dharug and Macquarie Pass National Parks are among the places where this species is conserved. Waratahs are cultivated north of Sydney and in the Dandenong Ranges, Victoria. They are grown in Israel, New Zealand and Hawaii for the cut flower trade. It was introduced to England in 1789 but can’t survive English winters out of doors except in the south-west coastal regions, and it seldom flowers in glasshouses. It is also cultivated in California.

waratah belt buckleWhen the Australian flora started to influence artists and craftsmen of European origin, the Waratah was adopted as a motif. The Museum of Applied Arts and Sciences in Sydney has a important collection of arts and crafts featuring styles primarily based on the Waratah. The diversity of media used in the collection incorporate suede, stained glass, bone china and earthenware, glassware, copper, bronze, and wood. In 1915, R. T. Baker, a passionate advocate of the waratah (and other regional flora) as a motif in art, craft and industry, wrote:

‘The whole plant (waratah) lends itself to such a boldness of artistic concepts in all branches of Applied Art that it has couple of compeers amongst the representatives of the entire floral world…’

A little later artists like Margaret Preston utilised the bold shape of the Waratah in her hand-coloured woodcut prints.

Several government authorities and community groups in New South Wales use the Waratah in their insignia, usually adopting a stylised version of the flowerhead. It was depicted on the three shilling stamp, one of a set issued in 1959 illustrating Australian flora. Margaret Stones, an Australian botanical artist then attached to the employees of Kew Gardens, London, made the stamp. The Waratah was utilized once again on the 30 cent stamp as part of a State floral emblem set issued on ten July 1968.

Bag o’ Cash

Image by axoplasm

Chinese cash is funny for 6 motives.

1. Newer bills (after about 1999) all picture Chairman Mao, regardless of denomination.

2. There are bills for little denominations (less than 1 yuan). So there are 1, 2, and five jiao bills. A jiao is 1/ten of a yuan. This is like printing halfpenny bills.

3. The Chinese use money for everything. I have never ever noticed a check, either private or cashiers (most expats get paid in cash we get a transfer like direct deposit). And quite quite few areas take credit cards. In fact, I can consider of only two: the Marco Polo hotel, and the Esprit store.

4. The largest denomination is 100 yuan (about ). Combine this with #two (above) and you get a predicament exactly where, for instance, when you have to pay the travel agent 10,000 yuan, that means going to the bank, waiting in line for two hours (yes, that’s how extended it normally requires, in component due to the fact everyone insists on counting these [I AM NOT Generating THIS UP] bricks of cash in suitcases), filling out 4 types and photocopying your passport, and obtaining a literal BAG OF Money which all but has "$" stamped on the side. I particularly enjoy paying our rent this way.

five. The Chinese appreciate counting money. No a single trusts that they are getting the anticipated amount of money. Even when it is the FREAKING BANK that is giving it to them. Every person expects you to count all 200 bills by hand. This is basically protocol. Chinese people find out to count money by folding it at the corner and peeling by means of it really quickly. They find foreigners tediously counting money utilizing two hands truly hilarious.

6. The 100 yuan bill is PHYSICALLY a lot larger than the other denominations, and a lot bigger than non-Chinese wallets. I had to get a new wallet, for instance, WHICH I HATE. I like tiny skinny wallets but Chinese wallets are these gigantic pelvis busters.