Some cool precision turning and machining pictures:

Steven F. Udvar-Hazy Center: View of south hangar, like B-29 Superfortress “Enola Gay”, a glimpse of the Air France Concorde, and several others

Image by Chris Devers

Quoting Smithsonian National Air and Space Museum | Boeing B-29 Superfortress "Enola Gay":

Boeing’s B-29 Superfortress was the most sophisticated propeller-driven bomber of Planet War II and the very first bomber to residence its crew in pressurized compartments. Although made to fight in the European theater, the B-29 located its niche on the other side of the globe. In the Pacific, B-29s delivered a range of aerial weapons: standard bombs, incendiary bombs, mines, and two nuclear weapons.

On August 6, 1945, this Martin-constructed B-29-45-MO dropped the 1st atomic weapon utilised in combat on Hiroshima, Japan. 3 days later, Bockscar (on display at the U.S. Air Force Museum close to Dayton, Ohio) dropped a second atomic bomb on Nagasaki, Japan. Enola Gay flew as the advance weather reconnaissance aircraft that day. A third B-29, The Great Artiste, flew as an observation aircraft on each missions.

Transferred from the United States Air Force.

Manufacturer:

Boeing Aircraft Co.

Martin Co., Omaha, Nebr.

Date:

1945

Country of Origin:

United States of America

Dimensions:

Overall: 900 x 3020cm, 32580kg, 4300cm (29ft six 5/16in. x 99ft 1in., 71825.9lb., 141ft 15/16in.)

Materials:

Polished overall aluminum finish

Physical Description:

Four-engine heavy bomber with semi-monoqoque fuselage and higher-aspect ratio wings. Polished aluminum finish overall, normal late-Planet War II Army Air Forces insignia on wings and aft fuselage and serial number on vertical fin 509th Composite Group markings painted in black "Enola Gay" in black, block letters on lower left nose.

Steven F. Udvar-Hazy Center: Hawker Hurricane Mk. IIC, with Northrop P-61C Black Widow, B-29 Superfortress “Enola Gay”, and SR-71 Blackbird in the background

Image by Chris Devers

See a lot more images of this, and the Wikipedia report.

Specifics, quoting from Smithsonian National Air and Space Museum: Steven F. Udvar-Hazy | Hawker Hurricane Mk. IIC:

Hawker Chief Designer Sydney Camm’s Hurricane ranks with the most important aircraft designs in military aviation history. Made in the late 1930s, when monoplanes were deemed unstable and too radical to be productive, the Hurricane was the first British monoplane fighter and the initial British fighter to exceed 483 kilometers (300 miles) per hour in level flight. Hurricane pilots fought the Luftwaffe and helped win the Battle of Britain in the summer season of 1940.

This Mark IIC was constructed at the Langley factory, close to what is now Heathrow Airport, early in 1944. It served as a education aircraft in the course of the World War II in the Royal Air Force’s 41 OTU.

Donated by the Royal Air Force Museum

Manufacturer:

Hawker Aircraft Ltd.

Date:

1944

Nation of Origin:

United Kingdom

Dimensions:

Wingspan: 12.2 m (40 ft)

Length: 9.8 m (32 ft 3 in)

Height: 4 m (13 ft)

Weight, empty: two,624 kg (five,785 lb)

Weight, gross: 3,951 kg (eight,710 lb)

Prime speed:538 km/h (334 mph)

Engine:Rolls-Royce Merlin XX, liquid-cooled in-line V, 1,300 hp

Armament:4 20 mm Hispano cannons

Ordnance:two 250-lb or two 500-lb bombs or eight three-in rockets

Supplies:

Fuselage: Steel tube with aircraft spruce forms and fabric, aluminum cowling

Wings: Stressed Skin Aluminum

Horizontal Stablizer: Pressure Skin aluminum

Rudder: fabric covered aluminum

Handle Surfaces: fabric covered aluminum

Physical Description:

Hawker Hurricane Mk. IIC single seat, low wing monoplane ground attack fighter enclosed cockpit steel tube fuselage with aircraft spruce forms and fabric, aluminum cowling, stressed skin aluminum wings and horizontal stablizer, fabric covered aluminum rudder and handle surfaces grey green camoflage prime surface paint scheme with dove grey underside red and blue national roundel on upper wing surface and red, white, and blue roundel decrease wing surface red, white, blue, and yellow roundel fuselage sides red, white and blue tail flash Rolls-Royce Merlin XX, liquid cooled V-12, 1,280 horsepower engine Armament, 4: 20mm Hispano cannons.

• • • • •

See far more images of this, and the Wikipedia article.

Particulars, quoting from Smithsonian National Air and Space Museum: Steven F. Udvar-Hazy | Northrop P-61C Black Widow:

The P-61 Black Widow was the first U.S. aircraft developed to locate and destroy enemy aircraft at evening and in bad weather, a feat produced attainable by the use of on-board radar. The prototype first flew in 1942. P-61 combat operations started just following D-Day, June 6, 1944, when Black Widows flew deep into German airspace, bombing and strafing trains and road site visitors. Operations in the Pacific began at about the identical time. By the end of World War II, Black Widows had seen combat in every single theater and had destroyed 127 enemy aircraft and 18 German V-1 buzz bombs.

The Museum’s Black Widow, a P-61C-1-NO, was delivered to the Army Air Forces in July 1945. It participated in cold-weather tests, higher-altitude drop tests, and in the National Thunderstorm Project, for which the top turret was removed to make area for thunderstorm monitoring gear.

Transferred from the United States Air Force.

Manufacturer:

Northrop Aircraft Inc.

Date:

1943

Country of Origin:

United States of America

Dimensions:

All round: 450 x 1500cm, 10637kg, 2000cm (14ft 9 3/16in. x 49ft 2 9/16in., 23450.3lb., 65ft 7 3/8in.)

• • • • •

Quoting Smithsonian National Air and Space Museum | Boeing B-29 Superfortress "Enola Gay":

Boeing’s B-29 Superfortress was the most sophisticated propeller-driven bomber of Globe War II and the 1st bomber to house its crew in pressurized compartments. Although made to fight in the European theater, the B-29 discovered its niche on the other side of the globe. In the Pacific, B-29s delivered a assortment of aerial weapons: traditional bombs, incendiary bombs, mines, and two nuclear weapons.

On August six, 1945, this Martin-built B-29-45-MO dropped the first atomic weapon utilised in combat on Hiroshima, Japan. Three days later, Bockscar (on show at the U.S. Air Force Museum close to Dayton, Ohio) dropped a second atomic bomb on Nagasaki, Japan. Enola Gay flew as the advance weather reconnaissance aircraft that day. A third B-29, The Great Artiste, flew as an observation aircraft on both missions.

Transferred from the United States Air Force.

Manufacturer:

Boeing Aircraft Co.

Martin Co., Omaha, Nebr.

Date:

1945

Country of Origin:

United States of America

Dimensions:

All round: 900 x 3020cm, 32580kg, 4300cm (29ft 6 5/16in. x 99ft 1in., 71825.9lb., 141ft 15/16in.)

Components:

Polished general aluminum finish

Physical Description:

4-engine heavy bomber with semi-monoqoque fuselage and higher-aspect ratio wings. Polished aluminum finish all round, standard late-Globe War II Army Air Forces insignia on wings and aft fuselage and serial number on vertical fin 509th Composite Group markings painted in black "Enola Gay" in black, block letters on decrease left nose.

• • • • •

See much more photographs of this, and the Wikipedia article.

Details, quoting from Smithsonian National Air and Space Museum | Lockheed SR-71 Blackbird:

No reconnaissance aircraft in history has operated globally in a lot more hostile airspace or with such total impunity than the SR-71, the world’s quickest jet-propelled aircraft. The Blackbird’s overall performance and operational achievements placed it at the pinnacle of aviation technologies developments during the Cold War.

This Blackbird accrued about 2,800 hours of flight time for the duration of 24 years of active service with the U.S. Air Force. On its final flight, March 6, 1990, Lt. Col. Ed Yielding and Lt. Col. Joseph Vida set a speed record by flying from Los Angeles to Washington, D.C., in 1 hour, four minutes, and 20 seconds, averaging three,418 kilometers (two,124 miles) per hour. At the flight’s conclusion, they landed at Washington-Dulles International Airport and turned the airplane more than to the Smithsonian.

Transferred from the United States Air Force.

Manufacturer:

Lockheed Aircraft Corporation

Designer:

Clarence L. "Kelly" Johnson

Date:

1964

Nation of Origin:

United States of America

Dimensions:

All round: 18ft 5 15/16in. x 55ft 7in. x 107ft 5in., 169998.5lb. (five.638m x 16.942m x 32.741m, 77110.8kg)

Other: 18ft five 15/16in. x 107ft 5in. x 55ft 7in. (5.638m x 32.741m x 16.942m)

Materials:

Titanium

Physical Description:

Twin-engine, two-seat, supersonic strategic reconnaissance aircraft airframe constructed largley of titanium and its alloys vertical tail fins are constructed of a composite (laminated plastic-sort material) to decrease radar cross-section Pratt and Whitney J58 (JT11D-20B) turbojet engines feature large inlet shock cones.

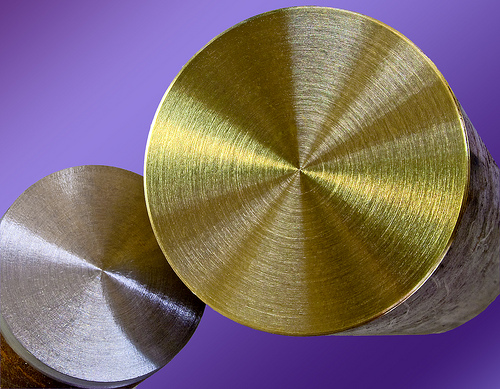

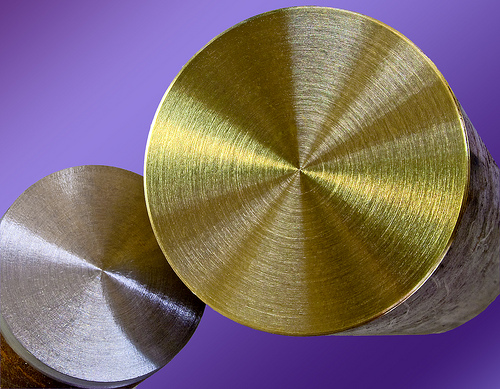

Steel and Brass

Image by tudedude

View On Black