http://www.cncmymodel.co.uk information@cncmymodel.com CNC MY MODEL is London based studio that offers CNC milling / routing digital fabrication and 3d modelling se…

Video Rating: five / 5

Service

Cool Precision Machine Service images

Check out these precision machine service images:

Steven F. Udvar-Hazy Center: Boeing B-29 Superfortress “Enola Gay” (front starboard view), with Grumman F6F-3 Hellcat at back-right, amongst other folks

Image by Chris Devers

See much more images of this, and the Wikipedia article.

Details, quoting from Smithsonian National Air and Space Museum: Steven F. Udvar-Hazy | Boeing B-29 Superfortress "Enola Gay":

Boeing’s B-29 Superfortress was the most sophisticated propeller-driven bomber of Planet War II and the first bomber to house its crew in pressurized compartments. Although made to fight in the European theater, the B-29 located its niche on the other side of the globe. In the Pacific, B-29s delivered a selection of aerial weapons: traditional bombs, incendiary bombs, mines, and two nuclear weapons.

On August six, 1945, this Martin-built B-29-45-MO dropped the initial atomic weapon employed in combat on Hiroshima, Japan. 3 days later, Bockscar (on show at the U.S. Air Force Museum close to Dayton, Ohio) dropped a second atomic bomb on Nagasaki, Japan. Enola Gay flew as the advance climate reconnaissance aircraft that day. A third B-29, The Wonderful Artiste, flew as an observation aircraft on both missions.

Transferred from the United States Air Force.

Manufacturer:

Boeing Aircraft Co.

Martin Co., Omaha, Nebr.

Date:

1945

Country of Origin:

United States of America

Dimensions:

Overall: 900 x 3020cm, 32580kg, 4300cm (29ft six 5/16in. x 99ft 1in., 71825.9lb., 141ft 15/16in.)

Components:

Polished general aluminum finish

Physical Description:

Four-engine heavy bomber with semi-monoqoque fuselage and high-aspect ratio wings. Polished aluminum finish overall, standard late-World War II Army Air Forces insignia on wings and aft fuselage and serial quantity on vertical fin 509th Composite Group markings painted in black "Enola Gay" in black, block letters on reduce left nose.

• • • • •

Quoting Smithsonian National Air and Space Museum | Grumman F6F-three Hellcat:

The Grumman F6F Hellcat was originally conceived as an sophisticated version of the U.S. Navy’s then present front-line fighter, the F4F Wildcat (see NASM collection). The Wildcat’s intended replacement, the Vought F4U Corsair (see NASM collection), very first flown in 1940, was showing excellent guarantee, but development was slowed by issues, such as the crash of the prototype.

The National Air and Space Museum’s F6F-3 Hellcat, BuNo. 41834, was built at Grumman’s Bethpage, New York, factory in February 1944 beneath contract NOA-(S)846. It was delivered to the Navy on February 7, and arrived in San Diego, California, on the 18th. It was assigned to Fighter Squadron 15 (VF-15) on USS Hornet (CV12) bound for Hawaii. On arrival, it was assigned to VF-three where it sustained harm in a wheels-up landing at NAS Barbers Point, Hawaii. After repair, it was assigned to VF-83 exactly where it was employed in a instruction role until February 21, 1945. Right after quite a few transfers 41834 was converted to an F6F-3K target drone with the installation of sophisticated radio-manage gear. It was painted red with a pink tail that carried the quantity 14. Its mission was to be employed in Operation Crossroads – the atomic bomb tests at Bikini Atoll. It flew on June 24, 1946, with a pilot, on a practice flight and was launched, unmanned, quickly after the initial bomb test. Instrumentation on board and photographic plates taped to the manage stick obtained data on radioactivity. Three a lot more manned flights preceded the final unmanned flight on July 25, 1946, which evaluated the first underwater explosion. Records indicate that exposure of this aircraft to the radioactive cloud was minimal and residual radiation is negligible.

F6F-3K 41834 was transferred to NAS Norfolk and logged its last flight on March 25, 1947, with a total of 430.two flying hours. It was assigned to the National Air Museum on November three, 1948, and remained at Norfolk till October 4, 1960, when it was moved by barge to Washington and placed in storage. In 1976 this Hellcat was loaned to the USS Yorktown Museum at Charleston, South Carolina. A superficial restoration was performed at the museum, but simply because of the harsh atmosphere and its poor condition the Hellcat was returned to NASM on March 16, 1982. In 1983, it was sent to Grumman Aerospace exactly where a team of volunteers fully restored the aircraft. In 1985, it was shipped back to the Paul E. Garber Preservation, Restoration and Storage Facility in Suitland, Maryland, and put in storage. NASM’s F6F-3 Hellcat is scheduled to be displayed in the new Steven F. Udvar-Hazy center at Dulles International Airport in Virginia in 2004.

Transferred from the United States Navy.

Manufacturer:

Grumman Aircraft Engineering Corporation

Date:

1943

Nation of Origin:

United States of America

Dimensions:

General: 338 x 1021cm, 4092kg, 1304cm (11ft 1 1/16in. x 33ft 5 15/16in., 9021.2lb., 42ft 9 three/8in.)

Physical Description:

Heavy armor plate, reinforced empennage, R-2800-10W engine, spring tabs on the ailerons (increased maneuverability), could carry rockets as properly as bombs.

427 SOHC Dyno run at Precision Machine Service

427 SOHC built and dyno tested at Precision Machine Service.

Tristateturbo.com is the North East leader in precision turbocharger machine shop services, offering certified military grade welding and high speed turbocha…

Video Rating: 5 / 5

CNC MY MODEL | London CNC milling service – Roughing pass on topographical model

http://www.cncmymodel.co.uk info@cncmymodel.com CNC MY MODEL is London primarily based studio that delivers CNC milling / routing digital fabrication and 3d modelling se…

ADLINK Announces SEMA Cloud, a Complete Device-to-Cloud Service Solution for Intelligent Remote Control, Monitoring and Configuration

San Jose, CA (PRWEB) August 26, 2014

ADLINK Technology, a leading global provider of cloud-based services, intelligent gateways and embedded building blocks for devices that enable the Internet of Things (IoT), today announced that all of its new embedded boards and systems will include a unified board management controller (BMC) and the latest SEMA (Smart Embedded Management Agent) technology, facilitating data exchange with the cloud. ADLINK’s SEMA Cloud allows users to securely monitor system status, diagnose problems, and handle system management tasks from anywhere, at any time, over the Internet. A demonstration of our SEMA Cloud technology is being showcased in ADLINK’s booth #978 at IDF14 from September 9-11 at Moscone Center West in San Francisco, CA.

The Internet of Things (IoT) approach takes today’s intelligent middleware a step further than previous generations of remote management technology. By employing cloud server architecture and an M2M (machine-to-machine) stack as part of the SEMA Cloud solution, embedded devices can be connected to the cloud without additional design requirements.

SEMA Cloud provides the entire infrastructure, including the client application that gathers local data on the device and pushes it securely to the cloud. SEMA Cloud also includes the cloud server, which is set up to store and process this data, as well as the application to remotely monitor, control and configure the devices.

With SEMA Cloud, users can remotely monitor power supply voltage, CPU temperature, fan rotation speed and other significant data to determine whether the system is operating within normal parameters and if preventive measures should be taken to avoid disruption of service.

SEMA’s alarm and event creation feature allows users to define alarm thresholds for several types of data, such as system voltage, CPU temperature or fan rotation speed. The threshold configurations are stored locally on the client to guarantee reactions very close to real-time. If any user-defined limits are reached, an alarm will be issued via SMS text message or email, and SEMA can even be setup to take direct action to prevent failure of the system. In many cases, system malfunctions can be resolved by simply restarting or reconfiguring the device. Providing this proactive maintenance capability is one way in which SEMA Cloud goes beyond existing remote management technology.

SEMA Cloud also provides remote diagnosis and troubleshooting functionality for system users or operators located at a distance, allowing them to rescue or repair systems without making a physical visit to field devices. If the system or any module is powered down in a failure, the BMC circuitry will still remain active and produce a forensic report on the cause of the failure.

These compelling features help to prevent or eliminate system downtime and reduce the workload of field service technicians and related personnel resource demands, therefore enhancing the reliability of the entire system and reducing maintenance and repair costs. The TCO (total cost of ownership) benefits are especially significant in large scale systems, such as those for traffic management and monitoring or urban security surveillance, when a great number of controllers and related peripheral devices are deployed in the field over wide areas.

In mission-critical application scenarios such as transportation, aviation, power plants, electrical grids and other utilities, or high-tech manufacturing facilities, an unexpected system shutdown could result in great economic damage or even human loss. ADLINK’s SEMA Cloud device-to-cloud solution can help to detect and solve problems in connected devices before they get out of hand, is ideally suited to serve a wide range of embedded solution customers across many different vertical markets, and makes our customers’ solutions more secure, reliable and intelligent.

ADLINK IPCs or embedded systems with SEMA Cloud built in can serve as an ideal gateway or platform for the Internet of Things applications. It enables the connectivity of legacy industrial devices and other systems to the IoT, extracts raw data from these devices, and determines which data to save and which to send to the cloud for further analysis. The results of data analysis can provide valuable information for policy decision-making and generate innovative business opportunities.

The newest SEMA Cloud 2.3 version is available now, with support of the latest-generation embedded processing architectures from Intel, AMD and ARM, including Intel’s next-generation 14 nm platform and 2nd generation AMD Embedded R-Series APU (formerly codenamed “Bald Eagle”). In addition, SEMA Cloud 2.3 supports multiple operating systems, including VxWorks and Windows Compact.

For more product information, please visit: http://www.adlinktech.com/sema/index.php

About ADLINK

ADLINK Technology is enabling the Internet of Things (IoT) with innovative embedded computing solutions for edge devices, intelligent gateways and cloud services. ADLINK’s products are application-ready for industrial automation, communications, medical, defense, transportation, and infotainment industries. Our product range includes motherboards, blades, chassis, modules, and systems based on industry standard form factors, as well as an extensive line of test & measurement products and smart touch computers, displays and handhelds that support the global transition to always connected systems. Many products are Extreme Rugged™, supporting extended temperature ranges, shock and vibration.

ADLINK is a Premier Member of the Intel® Internet of Things Solutions Alliance and is active in several standards organizations, including PCI Industrial Computer Manufacturers Group (PICMG), PXI Systems Alliance (PXISA), and Standardization Group for Embedded Technologies (SGeT).

ADLINK is a global company with headquarters in Taiwan and manufacturing in Taiwan and China; R&D and integration in Taiwan, China, the US, and Germany; and an extensive network of worldwide sales and support offices. ADLINK is ISO-9001, ISO-14001, ISO-13485 and TL9000 certified and is publicly traded on the TAIEX Taiwan Stock Exchange (stock code: 6166).

# # #

Intel is a trademark of the Intel Corporation in the United States and other countries. Windows is a registered trademark of Microsoft Corporation in the United States and other countries. All other trademarks are the property of their respective owners.

CNC China Milling Service UK

http://www.oldtownengineering.co.uk Old Town China Engineering Company Ltd, established in 1962, based in Swindon Wiltshire, was originally set up to give a comple…

Video Rating: 0 / 5

Returns slots, Mill Park Library, Yarra Plenty Library service

A few nice slot milling images I found:

Returns slots, Mill Park Library, Yarra Plenty Library service

Image by sirexkat

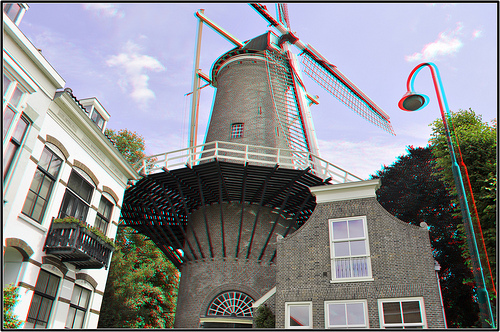

Molen ‘t Slot Gouda 3D

Image by wim hoppenbrouwers

anaglyph red/cyan

Slitting saw

Image by tudedude

Anderson China Machining Service, Inc. – Excellence In Precision CNC China Machining

Anderson China Machining Service, Inc. is a Precision CNC Contract China Machine Shop, specializing in machined components China and assemblies, run on a lean, just-in-time ba…

Precision CNC machining, China Prototyping, assembly Service

Most popular precision cnc China machining services eBay auctions:

[wprebay kw=”precision+cnc+machining+services” num=”0″ ebcat=”-1″]

[wprebay kw=”precision+cnc+machining+services” num=”1″ ebcat=”-1″]

Nice Precision China Machining Service photos

Some cool precision China machining service images:

Steven F. Udvar-Hazy Center: Photomontage of main entrance view, including P-40 Warhawk & F-4 Corsair up front, SR-71 Background below in the near distance, and the Space Shuttle Enterprise beyond

Image by Chris Devers

Blogged on ☛ HoloChromaCinePhotoRamaScope‽ as: Bye bye, Miss American Pie.

• • • • •

Quoting Smithsonian National Air and Space Museum | Curtiss P-40E Warhawk (Kittyhawk IA):

Whether known as the Warhawk, Tomahawk, or Kittyhawk, the Curtiss P-40 proved to be a successful, versatile fighter during the first half of World War II. The shark-mouthed Tomahawks that Gen. Claire Chennault’s "Flying Tigers" flew in China against the Japanese remain among the most popular airplanes of the war. P-40E pilot Lt. Boyd D. Wagner became the first American ace of World War II when he shot down six Japanese aircraft in the Philippines in mid-December 1941.

Curtiss-Wright built this airplane as Model 87-A3 and delivered it to Canada as a Kittyhawk I in 1941. It served until 1946 in No. 111 Squadron, Royal Canadian Air Force. U.S. Air Force personnel at Andrews Air Force Base restored it in 1975 to represent an aircraft of the 75th Fighter Squadron, 23rd Fighter Group, 14th Air Force.

Donated by the Exchange Club in Memory of Kellis Forbes.

Manufacturer:

Curtiss Aircraft Company

Date:

1939

Country of Origin:

United States of America

Dimensions:

Overall: 330 x 970cm, 2686kg, 1140cm (10ft 9 15/16in. x 31ft 9 7/8in., 5921.6lb., 37ft 4 13/16in.)

Materials:

All-metal, semi-monocoque

Physical Description:

Single engine, single seat, fighter aircraft.

• • • • •

Quoting Smithsonian National Air and Space Museum | Lockheed SR-71 Blackbird:

No reconnaissance aircraft in history has operated globally in more hostile airspace or with such complete impunity than the SR-71, the world’s fastest jet-propelled aircraft. The Blackbird’s performance and operational achievements placed it at the pinnacle of aviation technology developments during the Cold War.

This Blackbird accrued about 2,800 hours of flight time during 24 years of active service with the U.S. Air Force. On its last flight, March 6, 1990, Lt. Col. Ed Yielding and Lt. Col. Joseph Vida set a speed record by flying from Los Angeles to Washington, D.C., in 1 hour, 4 minutes, and 20 seconds, averaging 3,418 kilometers (2,124 miles) per hour. At the flight’s conclusion, they landed at Washington-Dulles International Airport and turned the airplane over to the Smithsonian.

Transferred from the United States Air Force.

Manufacturer:

Lockheed Aircraft Corporation

Designer:

Clarence L. "Kelly" Johnson

Date:

1964

Country of Origin:

United States of America

Dimensions:

Overall: 18ft 5 15/16in. x 55ft 7in. x 107ft 5in., 169998.5lb. (5.638m x 16.942m x 32.741m, 77110.8kg)

Other: 18ft 5 15/16in. x 107ft 5in. x 55ft 7in. (5.638m x 32.741m x 16.942m)

Materials:

Titanium

Physical Description:

Twin-engine, two-seat, supersonic strategic reconnaissance aircraft; airframe constructed largley of titanium and its alloys; vertical tail fins are constructed of a composite (laminated plastic-type material) to reduce radar cross-section; Pratt and Whitney J58 (JT11D-20B) turbojet engines feature large inlet shock cones.

• • • • •

Quoting Smithsonian National Air and Space Museum | Vought F4U-1D Corsair :

By V-J Day, September 2, 1945, Corsair pilots had amassed an 11:1 kill ratio against enemy aircraft. The aircraft’s distinctive inverted gull-wing design allowed ground clearance for the huge, three-bladed Hamilton Standard Hydromatic propeller, which spanned more than 4 meters (13 feet). The Pratt and Whitney R-2800 radial engine and Hydromatic propeller was the largest and one of the most powerful engine-propeller combinations ever flown on a fighter aircraft.

Charles Lindbergh flew bombing missions in a Corsair with Marine Air Group 31 against Japanese strongholds in the Pacific in 1944. This airplane is painted in the colors and markings of the Corsair Sun Setter, a Marine close-support fighter assigned to the USS Essex in July 1944.

Transferred from the United States Navy.

Manufacturer:

Vought Aircraft Company

Date:

1940

Country of Origin:

United States of America

Dimensions:

Overall: 460 x 1020cm, 4037kg, 1250cm (15ft 1 1/8in. x 33ft 5 9/16in., 8900lb., 41ft 1/8in.)

Materials:

All metal with fabric-covered wings behind the main spar.

Physical Description:

R-2800 radial air-cooled engine with 1,850 horsepower, turned a three-blade Hamilton Standard Hydromatic propeller with solid aluminum blades spanning 13 feet 1 inch; wing bent gull-shaped on both sides of the fuselage.

• • • • •

See more photos of this, and the Wikipedia article.

Details, quoting from Smithsonian National Air and Space Museum | Space Shuttle Enterprise:

Manufacturer:

Rockwell International Corporation

Country of Origin:

United States of America

Dimensions:

Overall: 57 ft. tall x 122 ft. long x 78 ft. wing span, 150,000 lb.

(1737.36 x 3718.57 x 2377.44cm, 68039.6kg)

Materials:

Aluminum airframe and body with some fiberglass features; payload bay doors are graphite epoxy composite; thermal tiles are simulated (polyurethane foam) except for test samples of actual tiles and thermal blankets.

The first Space Shuttle orbiter, "Enterprise," is a full-scale test vehicle used for flights in the atmosphere and tests on the ground; it is not equipped for spaceflight. Although the airframe and flight control elements are like those of the Shuttles flown in space, this vehicle has no propulsion system and only simulated thermal tiles because these features were not needed for atmospheric and ground tests. "Enterprise" was rolled out at Rockwell International’s assembly facility in Palmdale, California, in 1976. In 1977, it entered service for a nine-month-long approach-and-landing test flight program. Thereafter it was used for vibration tests and fit checks at NASA centers, and it also appeared in the 1983 Paris Air Show and the 1984 World’s Fair in New Orleans. In 1985, NASA transferred "Enterprise" to the Smithsonian Institution’s National Air and Space Museum.

Transferred from National Aeronautics and Space Administration