http://www.wolfgangengineering.com/ Here is my most recent Item I have to offer you. It is a CNC Rail Slide. Thanks for watching.

Video Rating: four / five

Router

mini cnc router generating relief/0404 wood cnc milling machine/China cnc router manufacturer

1. Functioning region: 400*400*120mm two. X/Y/Z square rails. For much more details, pls contact me as following: E-mail: ymsherryfan@gmail.com Skype: sherry_322 Tel: …

Video Rating: / five

The Most Advanced Desktop CNC Router Machine Has Been Created by Sophisticated Manage Technologies (ACT)

Granada Hills, CA (PRWEB) July 09, 2013

Advanced Manage technology (ACT) has announced their newest line of desktop milling machines and Benchtop milling machines. Made particularly for intricate milling perform, Sophisticated Control Technology (ACT) carries a total line of the greatest of machines at the most reasonable and affordable rates. ACT machines have been obtainable to the basic public because 2004, supplying only the very best good quality CNC machine technology. Special innovation is the essential aspect to ACT’s superior technology. ACT has invested a substantial quantity of time and cash in upgrading the technologies that’s utilized in their most recent line of CNC machine technologies. As a outcome of Advanced Control technology’s continuous efforts more than the years, ACT has come up with advanced CNC controller, which gives precision and top quality the likes of which has never ever been observed before.

Advanced Control technologies delivers the ideal of machines due to their really knowledgeable and talented group. Sophisticated Manage technology develops machines that are reliable, versatile, durable and most importantly lightweight. Pertaining to their objective, ACT offers not only a desktop milling machine program but also a Benchtop CNC machine that covers the least region and are lightweight. Needless to mention that the machines provided at ACT have high precisions.

Machines offered at ACT can be utilised for the delicate milling tasks as listed beneath:

Jewelry manufacturing

Engraving

3D mold producing

Research labs

PC board drilling

Dental applications

The makes use of of machines at ACT are not restricted to the ones talked about above. The above mentioned utilizes are some of the couple of out of the large quantity of utilizes ACT machines can be place to. Following their obsession to offer you the best of machines, ACT has come up with the next generation machine DMC-III, which delivers exceptional skilled efficiency. The DMC-III has currently been very common in the market place and some of its customers really feel that the DMC-III is the only desktop CNC machine, which is CNC enabled, that is suitable for very delicate perform.

Sophisticated Handle technology can be contacted at 818 363-6070 or go to their internet site at http://www.actmachines.com.

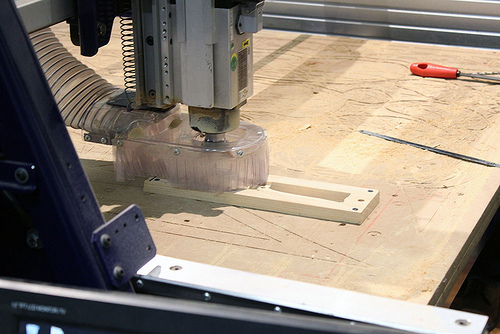

3D Milling with a CNC Router

Omnitech CNC Router Machining Strong Wood Components from Akhurst CNC

Omnitech Selexx CNC Router machining various strong wood components such as door, window, and furniture parts. For more info on our variety of woodwork…

Video Rating: / five

WEEKE BHC 550 Flat Table CNC Router cutting custom cabinet parts

This is a WEEKE flat table CNC Router cutting out a full sheet of custom cabinet components. This system consists of vertical drilling and routing with the major 16 …

Video Rating: / 5

Developing CNC Router Components CRP4848-17.MPG

First movements.

Video Rating: 4 / 5

CNC Wood Router

A CNC wood router is a Numerical control tool that creates objects from wood. Parts of a project can be made and then assembled using a router to produce a complete project.

The CNC router works like a printer. Work is composed on a computer and then the design or drawing is sent to the CNC router for the hard copy. This outputs a 3-dimensional copy of the work. The CNC router uses a cutting tool instead of an ink jet.

The cutting tool is generally a router but other cutters can be used as well.

The CNC works on the Cartesian coordinate system (X, Y, Z) for 3D motion control. CNC stands for computer numerically controlled cutting tool. This gives the computer a printer like ability to drive a CNC machine to make parts.

For engraving and general purpose cutting all that is needed is some material to engrave or cut on and an engraving or cutting tool bit.

A file of a picture or part has to be converted to g-code. Clamp the work piece down and then use the driver program to zero the CNC and run the g-code file. This will command the CNC to make the desired parts for you, quickly and accurately. Use it for all kinds of projects to make PCBs, gears, molds, etc.

The CNC Router is great for hobbies, engineering prototyping, product development, art, robotic education, and production work.

How it works

A CNC wood router uses CNC (computer numerical control) and is similar to a metal CNC mill with the following differences:

àThe wood router typically spins faster — with a range of 13,000 to 24,000 RPM

àLow end hobby grade machines typically uses smaller tools — typical shank size 20 mm or at most 25 mm. Professional quality machines frequently use surface facing tools up to 3″ in diameter or more, and spindle power exceeding 15 horsepower. China Machines capable of routing heavy material at many hundreds of inches per minute are common.

àSome machines use smaller toolholders MK2 (Morse taper #2 – on older machines), ISO-30, HSK-63 or the tools just get held in a collet tool holder affixed directly to the spindle nose. ISO-30 and HSK-63 are rapid-change toolholding systems. HSK-63 has begun to supplant the ISO-30 as the rapid change standard in recent years.

A wood router is controlled in the same way as a metal mill, but there is a lot of CAM and CAD software like Artcam, Mastercam, Bobcad, and Featurecam specifically for wood routers.

Wood with different grain must be approached with unique strategies, and wood CAM software is less likely to need to have hog-out strategies than the metal ones. Wood routers are frequently used to machine other soft materials such as plastics at high speed.

Typical three-axis CNC wood routers are generally much bigger than their metal shop counterparts. 5′ x 5′, 4′ x 8′, and 5′ x 10′ are typical bed sizes for wood routers. But can be built to accommodate very large sizes up to, but not limited to 12′ x 100′. Most table routers use a three motor drive system (xyz) utilizing either servo or stepper motors that drive the router motor via a gantry system. The gantry system isolates the XYZ movement in the top part of the machine with a stationary table holding the workpiece. Many CNC metal mills have the cutter motor moving on the Z axis, and a table which moves in X and Y for added stability.

Many wood routers can run at machining speeds of 25 metres/min (linear) or faster with a few machines such as the Anderson capable of 40 metres/min, Onsrud capable of 86 metres/min.

For more information on CNC Wood Router you can visit http://www.homag-india.com/

This is Jon from Indian SEO, you can check Homag India Website for Woodworking machines.

3Axis CNC 6040 1.5KW CNC China Engraving machine milling cnc router machine UK Ship

cnc milling uk eBay auctions you should keep an eye on:

[wprebay kw=”cnc+milling+uk” num=”3″ ebcat=”-1″]

Building my CNC Router – Part I

[youtube http://www.youtube.com/watch?v=yLfHb9LRWuc&fs=1&rel=0]

http://www.cnc4everyone.com – Check out my website for help and information on everything CNC http://www.joshendy.net – My new blog, going to be updating thi…

Video Rating: 4 / 5

[youtube http://www.youtube.com/watch?v=6SnF2aCb4UU&fs=1&rel=0]

This video briefly shows a custom CNC’d lower swing arm for an HPI SAVAGE RC truck that I designed and cut a prototype of in 6061 billit aluminium. This heat…

Video Rating: 5 / 5