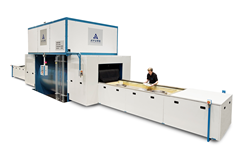

A machine press, commonly shortened to press, is a machine tool that alterations the shape of a operate piece. A mechanical press is a device designed to apply quite high force to kind, shape, or reduce supplies, to compress solids, or to extract liquids. Mechanical presses range in size from very modest units that are operated by hand, to massive powered industrial units used in manufacturing and assembly line applications. For example, a basic hand press can be employed to take away a bearing from a machine assembly, or a huge press might be used to stamp sheet metal into the curved shapes employed to construct automobile bodies.

An industrial mechanical press is generally utilized for shearing, bending, or forming sheet metal. It usually consists of a structural frame, reduce stationary base, and an upper ram that moves along a vertical axis to apply a force. The component that moves along the axis and applies the force is known as the ram. There are different frame styles and mechanical configurations for the ram, to meet the functional needs of the press.

There are different mechanisms to generate the force employed in a mechanical press. A hydraulic press makes use of 1 or more cylinders, and fluid at really high pressure, to move a cylinder piston and generate the force. Pneumatic presses are comparable to hydraulic presses, but use pressurized air versus fluid. A mechanical press is powered by an electric motor that drives a massive flywheel, crank, and clutch. A servo-driven mechanical press employs higher precision motors to replace the flywheel, and permits greater control of force by means of the complete cycle of the ram.

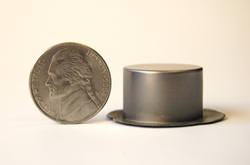

The quantity of force that a mechanical press can generate is identified as its capacity. Industrial presses are manufactured in a wide assortment of sizes and capacities, ranging from less that 1 ton to ten,000 tons or far more. Mechanical presses used in industrial applications frequently apply a number of tons of force to the objects being formed.

A die is frequently utilized in a mechanical press that is shaping, punching, or trimming a material. The die is mounted to the base of the press and has a profile that matches the shape of the portion being formed. The die gives the cutting surfaces, and a recessed space for the stamped or punched component to fall into.

There are numerous sorts of mechanical presses accessible to suit a assortment of applications. Widespread industrial uses for a mechanical press contain punching, which creates an open hole in sheet metal by removing an internal section of the material stamping, which types sheet metal into a helpful shape and bending, which shapes sheet metal around a straight axis. Other utilizes contain extracting liquids, such as oil extraction from olives for creating olive oil and compressing solids, like the mechanical presses employed to crush vehicles in automotive scrap yards.

The author is connected with IPFonline

http://www.ipfonline.com is India’s No. 1 Industrial Item Finder. The portal is a veritable storehouse of details on industrial products/solutions.