Serving customers in the transportation, agriculture, medical, and electrical industries, Screw Machine Specialties Precision CNC turning solutions of metal a…

Video Rating: / five

Rapid Prototyping China

Serving customers in the transportation, agriculture, medical, and electrical industries, Screw Machine Specialties Precision CNC turning solutions of metal a…

Video Rating: / five

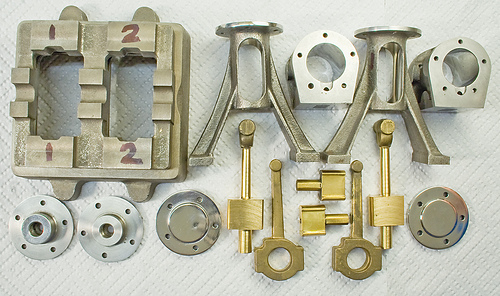

Some cool precision machining parts photos:

A Disassembly of parts

Image by tudedude

Some of the parts of the Stuart D10 Twin Cylinder Steam engine. Some parts are completely machined some are awaiting their fate in the near future.

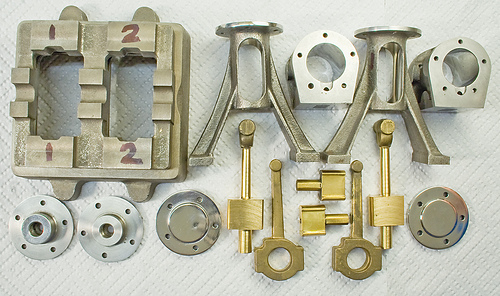

Machining a Standard bore and leading

Image by tudedude

Second part of machining the requirements

Grinding back lead instances

Up till recently Helander had sub-contracted any grinding operate that it needed performing, but this changed when it invested in a couple of second hand grinders to fulfil a contract for a client in the oil & gas sector for elements with carbide embedded …

Read far more on Engineering Capacity

Interview: A new way to recognize the human brain

Opsins can be engineered for diverse properties, including improved radiance, the level of which tracks the membrane voltage changes with high temporal precision. We used directed evolution of opsins … slow, tedious, costly and error prone. We …

Study far more on Forum:Blog (blog)

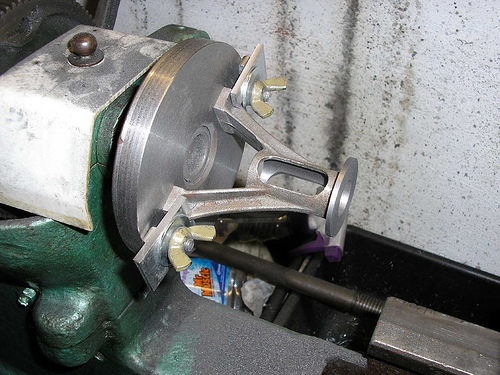

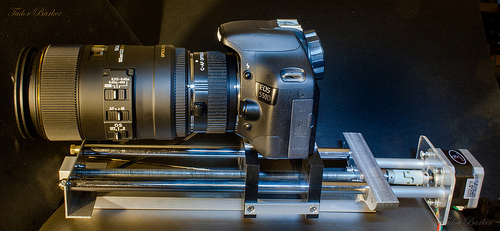

Some cool precision engineering elements photos:

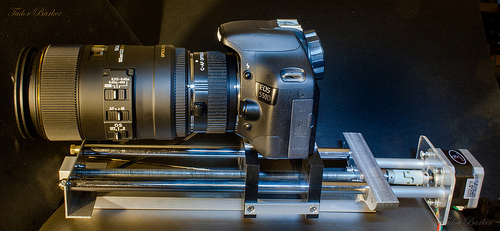

Digital Macro Stacking Concentrate Rail

Image by tudedude

Experimental Focus Rail Driven by a Nema 17 Stepper Motor and controlled by a an Arduino Nano.

Back in the day, generating a model or prototype needed you to begin with a chunk of some raw material such as clay, wood, or metal, and to gradually chip away at it till it formed the prototype of your design and style. This is usually known as subtractive manufacturing, since it requires subtracting from the original material to develop your prototype or solution. Additive manufacturing requires a distinct approach – the opposite method, in truth. Rather of subtracting layers of components, it progressively adds layers exactly where they are required in order to form the prototype. This process is specifically valuable when it comes to metal prototyping.

Additive manufacturing is specifically beneficial in the location of metal prototyping for a selection of factors. One particular of the most distinctive properties of metal is that it is difficult. This implies that a metal prototype will be sturdy and can even be used in production. But since metal is so difficult, it can also be tough to reduce into with accuracy to form a model by subtractive manufacturing. In reality, it can be extremely challenging to produce an accurate model or prototype by this strategy. It comes with a lot of challenges, and that is why it is hardly ever utilised any longer.

By sintering thin layers of powdered metal to 1 an additional, you can gradually add to your prototype until you have a completed model. Additive manufacturing tends to make it significantly easier to form metal prototypes with precision. Rather of chipping away at hardened metal, attempting not to do any more harm than essential, metal sintering makes it possible for you to bond with each other powdered metal one particular layer at a time. Every layer is only twenty microns thick, so you can attain unparalleled levels of detail in your metal prototyping by making use of this strategy. Making a metal prototype has never ever been easier or a lot more accurate.

It is critical for metal prototyping to be as precise as attainable. These metal prototypes are generally utilized as parts in machines, and if they are not built precisely to specifications, they can result in harm to important machinery. Additive manufacturing permits you to develop precise prototypes with out getting to manufacture them in bulk just before you are confident that the style is just proper for what you need. Getting capable to build a precise metal prototype that you can actually use signifies that you will be in a position to reach a design and style conclusion considerably more quickly than you would have been in a position to if you had utilised less accurate prototypes.

Go to http://www.directedMFG.com for more details regarding why this business is a single of the best additive manufacturing firms in the planet. As 1 of the premier metal prototyping firms, DirectedMFG continues to offer its customers with goods and solutions that meet and exceed expectations. Make contact with DirectedMFG nowadays by calling 714-546-1113.

Busch Precision buys Maintenance Service Corp. of West Allis

Busch Precision Inc. has purchased the machine tool service and repair, and CNC retrofitting company of Upkeep Service Corp. of West Allis. Based in Milwaukee, Busch Precision will operate the Maintenance Service Division out of Busch's headquarters …

Read a lot more on Milwaukee Business Journal

Existing pulse

Combining Rollomatic's R&D, purchasing power, and other sources, Strausak continues to develop precision CNC grinding machines, such as the 5-axis Fleximat. As one of the very first users of the NUM handle and Numroto tool grinding … specializes in CCM …

Read much more on Today’s Healthcare Developments

Higher Put on Resistant Elements for the Hydro Excavation Market

Mechanical excavators have a quantity of strong advantages for their users, but potentially the most significant is the speed at which they can operate, which can save consumers a great deal of time. The major situation with mechanical excavation, nonetheless, is …

Study far more on Azom.com

US strike targets leader of Somali extremist group

They struck using a number of hellfire missiles and precision-guided munitions. A witness in Somalia described … A missile strike in January killed a high-ranking intelligence officer for al-Shabab, and final October a vehicle carrying senior members of …

Study far more on Colorado Springs Gazette

Transfer Machining Center Produces Modest Precision Parts

The s100multi transfer machining center from Bumotec, portion of the Starrag Group, is said to deliver high-speed acceleration of three g (27.24 m/sec.²) with minimum chip-to-chip occasions of .five sec., thanks to linear motors in all axes. The transfer center …

Study more on Modern day Machine Shop

427 SOHC built and dyno tested at Precision Machine Service.

Tristateturbo.com is the North East leader in precision turbocharger machine shop services, offering certified military grade welding and high speed turbocha…

Video Rating: 5 / 5

Check out these precision engineering solutions images:

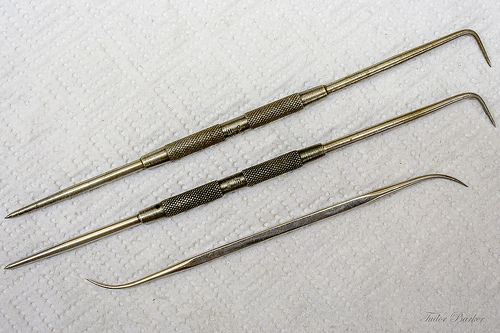

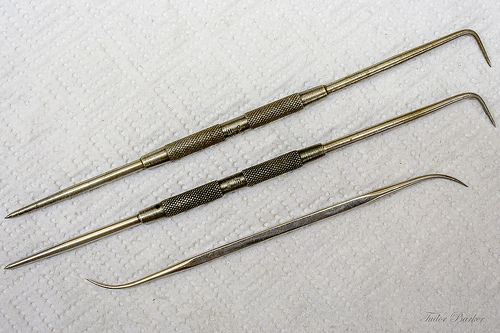

Marking Out Scribers

Image by tudedude

Utilized for scribing lines on metal – the lower of the 3 is a Dental Choose that has been pressed into service.

2ID Living Insignia – Historic Photo – 21 May 2009 – US Army Korea – Second Infantry Division

Image by U.S. Army Korea (Historical Image Archive)

imcom.korea.army.mil

2nd ID Warriors form ‘living insignia’ for 2nd time in division history

By Master Sgt. Michael Pintagro

2nd Infantry Division Public Affairs

Around 5,000 Warriors from the 2nd Infantry Division created a human version of the division’s distinctive Indianhead patch for only the second time in an organizational history dating from Globe War I Thursday morning (May possibly 21) at Indianhead Stage Field on Camp Casey, Korea.

A steady drizzle that persisted throughout the occasion may have dampened the Warriors’ wet climate gear and dress uniforms but it didn’t dampen the Soldiers’ resolve to take part in an historic event.

Organizers placed the initial human elements of the division patch around six a.m. and continued to develop the insignia throughout the early morning, adding Warriors to the huge formation as they marched onto the field as firms, platoons and detachments. Various dress uniforms replicated the insignia color scheme.

The insignia was constructed from the middle out, with the most intricate portions of the pattern established initial and the masses of Soldiers replicating the exterior placed final.

The division’s commanding basic, command sergeant key and senior staff stood at the base of the insignia. About 9:25 the assembled Warriors looked up and a tiny army of division photographers – several mounted 35 feet high in mechanical “cherry pickers” – commenced snapping shots.

Maj. Gen. John W. Morgan III, the commanding basic, addressed his Soldiers following the second-of-its sort “photo op” in division history.

“Great job,” he told them. “You are component of history and part of the great 2nd Infantry Division. I’m proud of every and each and every one particular of you. Thank you for your service to the nation and to this wonderful division.”

Warriors of all ranks, roles and career fields from organizations and installations across the division’s footprint in Korea joined their leaders in the “patch.”

According to 2nd Lt. Michael Nuclo, the division engineer operations officer and a essential event organizer, leaders created a conscious effort to include all division units and ranks. “We’ll have Soldiers from every important division hub,” he said ahead of the occasion. “They’re coming from (camps) Hovey, Casey, Camp Red Cloud, Humphrey and K-16.”

Participants expressed enthusiasm for the opportunity to play a unique function in division history.

“When I very first got to Korea they took us to the 2nd ID Museum and showed us the original patch image and mentioned if we had been right here lengthy adequate we might get a likelihood to recreate it,” stated Pfc. Isaac Buckman of Company F, 333rd Target Acquisition Battery, 210th Fires Brigade. “I thought that was truly cool, and it is fantastic that I genuinely had an chance to do it.”

“This will go down in history and will always be remembered,” added Pvt. Jeremiah Heard of Battery E, 143rd Air Defense Artillery, 210th Fires Brigade. Other Soldiers, he predicted, “will really like it and they will wish they could do it just the exact same way that we did.”

Occasion organizers seemed equally inspired by their achievement and relieved it came off with out a hitch.

“This was a deliberate operation like everything else we do in this division,” said Lt. Col. Michael Anastasia, the division G-3 (operations officer) and the major figure in the planning and execution of the living insignia. “The occasion was meticulously planned and executed precisely according to that strategy.”

“Everything went extremely properly,” mentioned Lt. Col. Leroy Sharpe, the division engineer. “We knew it was going to rain and we planned for it. I’m glad it all came with each other so properly. It was an honor and privilege to be portion of history nowadays.”

“I believe it went quite well,” added Sgt. 1st Class Kyle Roberts, the NCOIC of the division engineer shop. “It feels fairly excellent to be component of an event like this that hopefully will last one more 84 years.”

The ceremony recreated an occasion carried out 84 years ago at Fort Sam Houston, Texas, which served as division headquarters for the duration of the period amongst the World Wars.

“It’s the initial time this has been accomplished considering that 1925,” said William M. Alexander, the 2nd ID museum director and division historian. Organizational pride, heritage and esprit de corps, the retired Army colonel added, motivated both “living insignia” ceremonies.

“Living insignia” formations, Alexander noted, “were broadly common during the ‘20s – that was probably the higher point of their reputation. Maj. Gen. Morgan had the vision to do this once more.”

Alexander mentioned he plans to show the new living insignia photo alongside the 1925 image in the museum foyer.

Event organizers confronted daunting engineering, mechanical and logistical challenges. Conducting a five,000-Soldier formation, with all its inherent transportation and scheduling troubles, represents a significant feat in itself. Occasion and unit leaders worked tirelessly to ensure consistency in uniform and precision in placement.

Division engineers faced a particularly daunting task: determining and implementing the appropriate configuration and dimensions. This required engineers to establish models projecting the most likely appearance of the Soldiers from a vantage point 35 feet higher and to the front of the formation, and arranging five,000 Warriors in accordance with that vision.

“We utilized computer models – there are mathematical equations we employed primarily based on the patch design and adjusting for the slope of the angle from 35 feet,” Nuclo mentioned.

“For all our technological positive aspects I’m not certain what we did was a lot distinct from what they did in 1925,” he added with a smile. “That was a generation of Americans that built a lot of amazing issues.”

Organizers and observers described the present as an excellent time for the division to recreate the insignia.

“Service on the Korean Peninsula is so crucial a component of the division’s heritage it is only acceptable they do this on the peninsula,” Alexander said. “The division suffered the highest number and proportion of casualties for the duration of the war and its members received the highest number of awards. More than half of the division’s service has been in Korea. It’s due to that Korean War legacy Gen. Douglas MacArthur stated, ‘No division I’ve ever commanded is greater than the 2nd ID.’”

“This is a time in the history of the division when the camaraderie and esprit de corps have by no means been larger,” Anastasia stated. “In my 21 years of service I’ve never ever been portion of an organization with such a spirit of brotherhood, so this was an excellent time to take the image.”

Nuclo drew an historical parallel among the generations of Warriors pictured in the previous and present living insignia photographs.

“The older guys in that image would have served in Planet War I, and most of the younger guys would serve later in World War II,” Nuclo said of the 1925 photo. “So you had a exclusive moment when most of the participants served in one particular of the two greatest wars of their era. Now our Soldiers are either on their way from or sooner or later going to Iraq or Afghanistan – the two wars of our era.”

For a lot more information about the U.S. Army in Korea pay a visit to us on-line at imcom.korea.army.mil

http://www.devindustries.org/] Welcome to Dev Industries Manufacturer & Supplier of Precision Engineered productsthe organization was established in 2006. Our Ri…

Video Rating: / 5

http://www.hada-industries.com/] Welcome to Hada Industries.Manufacturer and Exporter of Precision Engineered Merchandise.The business was established in the ye…

Video Rating: / five