Grinding 420 SS to .0002″ tolerance.

Video Rating: / 5

Precision

Nice International Precision Machining pictures

A handful of nice international precision machining photos I discovered:

Steven F. Udvar-Hazy Center: south hangar panorama, like Grumman G-22 “Gulfhawk II”, Boeing 367-80 (707) Jet Transport, Air France Concorde amongst other folks

Image by Chris Devers

Quoting Smithsonian National Air and Space Museum | North American P-51C, "Excalibur III":

On Could 29, 1951, Capt. Charles F. Blair flew Excalibur III from Norway across the North Pole to Alaska in a record-setting 10½ hours. Employing a technique of meticulously plotted "sun lines" he created, Blair was capable to navigate with precision where traditional magnetic compasses frequently failed. 4 months earlier, he had flown Excalibur III from New York to London in less than 8 hours, breaking the existing mark by over an hour.

Excalibur III 1st belonged to famed aviator A. Paul Mantz, who added further fuel tanks for lengthy-distance racing to this normal P-51C fighter. With it Mantz won the 1946 and 1947 Bendix air race and set a transcontinental speed record in 1947 when the airplane was named Blaze of Noon. Blair purchased it from Mantz in 1949 and renamed it Excalibur III, after the Sikorsky VS-44 flying boat he flew for American Export Airlines.

Present of Pan American Planet Airways

Manufacturer:

North American Aircraft Organization

Date:

1944

Nation of Origin:

United States of America

Dimensions:

Wingspan: 11.3 m (37 ft)

Length: 9.8 m (32 ft 3 in)

Height: three.9 m (12 ft 10 in)

Weight, empty: 4,445 kg (9,800 lb)

Weight, gross: 5,052 kg (11,800 lb)

Prime speed: 700 km/h (435 mph)

Supplies:

All round: Aluminum

Physical Description:

Single seat, single engine, low wing monoplane, World War II fighter modified for racing.

• • • • •

Quoting Smithsonian National Air and Space Museum | Grumman G-22 "Gulfhawk II":

1 of the most fascinating aerobatic aircraft of the 1930s and ’40s, the Grumman Gulfhawk II was constructed for retired naval aviator and air show pilot Al Williams. As head of the Gulf Oil Company’s aviation division, Williams flew in military and civilian air shows around the nation, performing precision aerobatics and dive-bombing maneuvers to promote military aviation throughout the interwar years.

The sturdy civilian biplane, with its strong aluminum monocoque fuselage and Wright Cyclone engine, practically matched the Grumman F3F common Navy fighter, which was operational at the time. It took its orange paint scheme from Williams’ Curtiss 1A Gulfhawk, also in the Smithsonian’s collection. Williams personally piloted the Gulfhawk II on its last flight in 1948 to Washington’s National Airport.

Gift of Gulf Oil Corporation

Manufacturer:

Grumman Aircraft Engineering Corporation

Date:

1936

Nation of Origin:

United States of America

Dimensions:

Wingspan: eight.7 m (28 ft 7 in)

Length: 7 m (23 ft)

Height: three.1 m (10 ft)

Weight, aerobatic: 1,625 kg (three,583 lb)

Weight, gross: 1,903 kg (four,195 lb)

Prime speed: 467 km/h (290 mph)

Engine: Wright Cyclone R-1820-G1, 1,000 hp

Components:

Fuselage: steel tube with aluminum alloy

Wings: aluminum spars and ribs with fabric cover

Physical Description:

NR1050. Aerobatic biplane flown by Main Alford "Al" Williams as demonstration aircraft for Gulf Oil Company. Related to Grumman F3F single-seat fighter aircraft flown by the U.S. Navy. Wright Cyclone R-1820-G1 engine, 1000 hp.

• • • • •

Quoting Smithsonian National Air and Space Museum | Boeing 367-80 Jet Transport:

On July 15, 1954, a graceful, swept-winged aircraft, bedecked in brown and yellow paint and powered by four revolutionary new engines first took to the sky above Seattle. Built by the Boeing Aircraft Firm, the 367-80, much better identified as the Dash 80, would come to revolutionize commercial air transportation when its developed version entered service as the famous Boeing 707, America’s first jet airliner.

In the early 1950s, Boeing had begun to study the possibility of making a jet-powered military transport and tanker to complement the new generation of Boeing jet bombers getting into service with the U.S. Air Force. When the Air Force showed no interest, Boeing invested million of its own capital to create a prototype jet transport in a daring gamble that the airlines and the Air Force would acquire it when the aircraft had flown and established itself. As Boeing had carried out with the B-17, it risked the organization on one roll of the dice and won.

Boeing engineers had initially based the jet transport on studies of enhanced designs of the Model 367, greater identified to the public as the C-97 piston-engined transport and aerial tanker. By the time Boeing progressed to the 80th iteration, the design bore no resemblance to the C-97 but, for security causes, Boeing decided to let the jet project be recognized as the 367-80.

Work proceeded rapidly after the formal start of the project on May possibly 20, 1952. The 367-80 mated a big cabin primarily based on the dimensions of the C-97 with the 35-degree swept-wing style based on the wings of the B-47 and B-52 but considerably stiffer and incorporating a pronounced dihedral. The wings were mounted low on the fuselage and incorporated high-speed and low-speed ailerons as properly as a sophisticated flap and spoiler method. Four Pratt & Whitney JT3 turbojet engines, every generating ten,000 pounds of thrust, had been mounted on struts beneath the wings.

Upon the Dash 80’s 1st flight on July 15, 1954, (the 34th anniversary of the founding of the Boeing Company) Boeing clearly had a winner. Flying 100 miles per hour more rapidly than the de Havilland Comet and significantly larger, the new Boeing had a maximum variety of more than three,500 miles. As hoped, the Air Force bought 29 examples of the design and style as a tanker/transport soon after they convinced Boeing to widen the design and style by 12 inches. Happy, the Air Force designated it the KC-135A. A total of 732 KC-135s have been constructed.

Rapidly Boeing turned its interest to promoting the airline market on this new jet transport. Clearly the market was impressed with the capabilities of the prototype 707 but never ever much more so than at the Gold Cup hydroplane races held on Lake Washington in Seattle, in August 1955. During the festivities surrounding this event, Boeing had gathered several airline representatives to take pleasure in the competition and witness a fly previous of the new Dash 80. To the audience’s intense delight and Boeing’s profound shock, test pilot Alvin "Tex" Johnston barrel-rolled the Dash 80 over the lake in complete view of thousands of astonished spectators. Johnston vividly displayed the superior strength and performance of this new jet, readily convincing the airline sector to purchase this new airliner.

In searching for a market, Boeing discovered a prepared buyer in Pan American Airway’s president Juan Trippe. Trippe had been spending a lot of his time looking for a suitable jet airliner to allow his pioneering firm to preserve its leadership in international air travel. Working with Boeing, Trippe overcame Boeing’s resistance to widening the Dash-80 style, now known as the 707, to seat six passengers in each and every seat row rather than five. Trippe did so by putting an order with Boeing for 20 707s but also ordering 25 of Douglas’s competing DC-8, which had but to fly but could accommodate six-abreast seating. At Pan Am’s insistence, the 707 was created 4 inches wider than the Dash 80 so that it could carry 160 passengers six-abreast. The wider fuselage created for the 707 became the common design for all of Boeing’s subsequent narrow-physique airliners.

Even though the British de Havilland D.H. 106 Comet and the Soviet Tupolev Tu-104 entered service earlier, the Boeing 707 and Douglas DC-eight had been bigger, quicker, had greater range, and have been more profitable to fly. In October 1958 Pan American ushered the jet age into the United States when it opened international service with the Boeing 707 in October 1958. National Airlines inaugurated domestic jet service two months later utilizing a 707-120 borrowed from Pan Am. American Airlines flew the 1st domestic 707 jet service with its own aircraft in January 1959. American set a new speed mark when it opened the very first regularly-scheduled transcontinental jet service in 1959. Subsequent nonstop flights amongst New York and San Francisco took only 5 hours – three hours much less than by the piston-engine DC-7. The one-way fare, including a surcharge for jet service, was 5.50, or 1 round trip. The flight was practically 40 % more quickly and practically 25 % more affordable than flying by piston-engine airliners. The consequent surge of site visitors demand was substantial.

The 707 was originally developed for transcontinental or a single-stop transatlantic range. But modified with added fuel tanks and more efficient turbofan engines, the 707-300 Intercontinental series aircraft could fly nonstop across the Atlantic with complete payload under any circumstances. Boeing constructed 855 707s, of which 725 were purchased by airlines worldwide.

Getting launched the Boeing Firm into the commercial jet age, the Dash 80 soldiered on as a hugely profitable experimental aircraft. Till its retirement in 1972, the Dash 80 tested quite a few sophisticated systems, several of which have been incorporated into later generations of jet transports. At one particular point, the Dash 80 carried three different engine kinds in its 4 nacelles. Serving as a test bed for the new 727, the Dash 80 was briefly equipped with a fifth engine mounted on the rear fuselage. Engineers also modified the wing in planform and contour to study the effects of diverse airfoil shapes. Numerous flap configurations have been also fitted which includes a highly sophisticated method of "blown" flaps which redirected engine exhaust more than the flaps to improve lift at low speeds. Fin height and horizontal stabilizer width was later improved and at one particular point, a specific multiple wheel low stress landing gear was fitted to test the feasibility of operating future heavy military transports from unprepared landing fields.

Following a long and distinguished profession, the Boeing 367-80 was ultimately retired and donated to the Smithsonian in 1972. At present, the aircraft is installated at the National Air and Space Museum’s new facility at Washington Dulles International Airport.

Gift of the Boeing Firm

Manufacturer:

Boeing Aircraft Co.

Date:

1954

Nation of Origin:

United States of America

Dimensions:

Height 19′ 2": Length 73′ 10": Wing Span 129′ eight": Weight 33,279 lbs.

Physical Description:

Prototype Boeing 707 yellow and brown.

• • • • •

Quoting Smithsonian National Air and Space Museum | Concorde, Fox Alpha, Air France:

The 1st supersonic airliner to enter service, the Concorde flew thousands of passengers across the Atlantic at twice the speed of sound for more than 25 years. Created and built by Aérospatiale of France and the British Aviation Corporation, the graceful Concorde was a spectacular technological achievement that could not overcome severe economic troubles.

In 1976 Air France and British Airways jointly inaugurated Concorde service to destinations around the globe. Carrying up to one hundred passengers in fantastic comfort, the Concorde catered to initial class passengers for whom speed was vital. It could cross the Atlantic in fewer than 4 hours – half the time of a standard jet airliner. Nonetheless its higher operating charges resulted in extremely higher fares that restricted the quantity of passengers who could afford to fly it. These troubles and a shrinking marketplace ultimately forced the reduction of service until all Concordes had been retired in 2003.

In 1989, Air France signed a letter of agreement to donate a Concorde to the National Air and Space Museum upon the aircraft’s retirement. On June 12, 2003, Air France honored that agreement, donating Concorde F-BVFA to the Museum upon the completion of its final flight. This aircraft was the very first Air France Concorde to open service to Rio de Janeiro, Washington, D.C., and New York and had flown 17,824 hours.

Gift of Air France.

Manufacturer:

Societe Nationale Industrielle Aerospatiale

British Aircraft Corporation

Dimensions:

Wingspan: 25.56 m (83 ft ten in)

Length: 61.66 m (202 ft 3 in)

Height: 11.3 m (37 ft 1 in)

Weight, empty: 79,265 kg (174,750 lb)

Weight, gross: 181,435 kg (400,000 lb)

Leading speed: 2,179 km/h (1350 mph)

Engine: Four Rolls-Royce/SNECMA Olympus 593 Mk 602, 17,259 kg (38,050 lb) thrust each

Manufacturer: Société Nationale Industrielle Aérospatiale, Paris, France, and British Aircraft Corporation, London, United Kingdom

Physical Description:

Aircaft Serial Number: 205. Which includes 4 (four) engines, bearing respectively the serial quantity: CBE066, CBE062, CBE086 and CBE085.

Also included, aircraft plaque: "AIR FRANCE Lorsque viendra le jour d’exposer Concorde dans un musee, la Smithsonian Institution a dores et deja choisi, pour le Musee de l’Air et de l’Espace de Washington, un appariel portant le couleurs d’Air France."

Deus Cantando / Winfried Ritsch, Peter Ablinger

Image by Ars Electronica

“DEUS CANTANDO” plays with the interpretive capacities of the human brain. Transcription application tends to make it achievable to reconstruct the frequency spectrum of a spoken text by signifies of a piano. Winfried Ritsch’s laptop-controlled piano performs the “composition” with consummate precision. Each and every one of the 88 electromechanical fingers is capable of up to 16 keystrokes per second. The interpretive capacities of the human brain then transform what have been initially abstract musical structures into a sequence of words in a human language. The outcome is an emphatic plea to save the Blue Planet and to defend human existence on Earth—the text of the 2009 Declaration of the International Environmental Criminal Court that was founded at the Planet Venice Forum pursuant to an initiative of Adolfo Pérez Esquivel and the Dalai Lama.

"DEUS CANTANDO (God, singing) for computer-controlled piano and screened text" is a operate by Peter Ablinger, Winfried Ritsch, Thomas Musil (AT). The work was developed at the Institue for Electronic Music Graz

credit: Robertba

Newest China Precision Parts News

INTERMACH Myanmar & SUBCON Myanmar 2014

There will also be four National Pavilions from Japan, Thailand, China and Taiwan featuring merchandise ranging from the most recent company tools to high-tech machinery and equipment. Spectacularly, this year's event will also function "Training on the Topic …

Study far more on PR Newswire UK (press release)

Book Review: 'How Google Functions' by Eric Schmidt and Jonathan Rosenberg

In “How Google Functions,” Eric Schmidt and Jonathan Rosenberg offer a firsthand account of how they and their inner circle created Google's early management methods by applying algorithmic precision to often complicated challenges. … However that famous …

Study much more on Wall Street Journal

Boeing components, bespoke medicines: As China rises, Singapore invests in …

Lien's Singapore factory makes higher-functionality components that aid hold the 737's landing gear with each other, an example of the specialized merchandise that are enabling the city to keep an industrial base even as labour costs climb. “We have to remain 1 step …

Read more on Monetary Post

Precision Linear Stage: Extended Travel, Low Profile, Higher Resolution

Auburn, MA (PRWEB) October 02, 2014

PI’s new M-417 linear stage provides 500 mm travel and half-micron resolution. This motorized precision positioner can be computer controlled for automation and precision assembly applications. The linear translation stage can manage higher duty cycles and boasts high velocity of one hundred mm/second. Precision recirculating ball bearings give guiding precision in the one hundred µrad range over the total travel range.

The low friction ball screw with a 2 mm thread pitch permits for maintenance free of charge operation and the integrated extremely effective PWM servo amplifier improves expense efficiency although simplifying installation and operation – no additional amplifier required. For instance, the M-417 can be driven by PI’s miniature, palm-prime C-863 Mercury servo motion controller.

Closed-Loop Operation, Limit & Reference Point Switches

An incremental optical rotary encoder with 4000 counts/rev controls the position delivering unidirectional repeatability of .5 µm. Non-contacting reference point and limit switches shield the mechanics from harm.

Dimensions and Application

The M-417 stage is 120 mm wide and 56 mm high. Its pressure-relieved aluminum base ensures the stage’s high stability. This low-profile positioning stage is well suited for automation and precision motion manage applications for science and market.

Far more info and datasheet: http://www.pi-usa.us/news/news_ka.php

Precision Linear Stage: Extended Travel, Low Profile, High Resolution

PI’s new M-417 linear stage gives 500 mm travel and half-micron resolution. This motorized precision positioner can be computer controlled for automation and precision assembly applications. The linear translation stage can manage high duty cycles and boasts higher velocity of one hundred mm/second. Precision recirculating ball bearings give guiding precision in the one hundred µrad variety over the complete travel range.

The low friction ball screw with a 2 mm thread pitch allows for upkeep free operation and the integrated extremely effective PWM servo amplifier improves expense efficiency although simplifying installation and operation – no added amplifier required. For instance, the M-417 can be driven by PI’s miniature, palm-best C-863 Mercury servo motion controller.

Closed-Loop Operation, Limit & Reference Point Switches

An incremental optical rotary encoder with 4000 counts/rev controls the position providing unidirectional repeatability of .5 µm. Non-contacting reference point and limit switches protect the mechanics from damage.

Dimensions and Application

The M-417 stage is 120 mm wide and 56 mm higher. Its stress-relieved aluminum base ensures the stage’s high stability. This low-profile positioning stage is well suited for automation and precision motion control applications for science and industry.

More info and datasheet:

http://www.pi-usa.us/news/news_ka.php

About PI

PI is a top manufacturer of precision motion control gear, piezo systems, piezo motors and actuators for semiconductor applications, photonics, bio-nano-technology and medical engineering. PI has been creating and manufacturing common & custom precision products with piezoceramic and electromagnetic drives for four decades. The company has been ISO 9001 certified considering that 1994 and supplies revolutionary, high-good quality options for OEM and research. PI is present worldwide with ten subsidiaries, R&D / engineering on three continents and total staff of 750+

Precision Machining Technology at Tri-C

The Precision Machining Technologies (PMT) system at Cuyahoga Community College (Tri-C®) just may be for you. PMT provides entry-level job talent training for …

Video Rating: 5 / 5

Newest Ultra Precision Machining News

STMicroelectronics Outlines Constantly-On 6-Axis Ultra-Efficiency Accelerometer …

Moreover, ST has leveraged its robust and mature manufacturing processes for the production of its business-leading micro-machined accelerometers and gyroscopes, even though manufacturing its IC interfaces employing CMOS technology. This option supports trimming …

Read far more on MarketWatch

Microsoft Devices Lures Consumers With Insurance Coverage On Lumia 930

Its Premium metal edges are sand blasted and precision machined to finely crafted specifics to generate a robust, slim and striking smartphone that's just merely lovely to look at, with the best of Microsoft built in." … The Lumia 930 also comes …

Study a lot more on Vanguard

Angelbird SSD2go Pocket External SSD Assessment (512GB)

This variety of ultra-transportable SSD proves that big issues come in small packages. Though it has a small stature, it is extremely robust and capable of taking all the abuse you can give it with its CNC machined aluminum housing. It is packed complete of …

Read more on The SSD Overview

Most recent Precision Machining Parts News

Manufacturing Day focuses on future

The company has about 200 staff at its primary facility in Trumbauersville and a sister plant in China, where they make machine-precision parts for every little thing from wind turbines to Harley-Davidson motorcycles. "I like it," the teen said. "It appears a …

Read far more on Bucks County Courier Instances

Good Precision Engineering Components pictures

Some cool precision engineering elements images:

Helping hands

Image by tudedude

Good Precision Machining images

A few good precision machining photos I discovered:

Okanagan’s Highland Trail gets renewed life

Image by BC Gov Photos

Thanks to a multi-level partnership between Recreation Sites and Trails BC, BC Parks and the Vernon Fire Zone to improve to Okanagan’s recreation opportunities, the Highland Trail is getting upgrades to make it safer and far more accessible for residents and visitors.

The first phase of the multi-phase improvement project is now comprehensive. The trailhead, in the northeast corner of Kalamalka Lake Provincial Park at Cosens Bay Gate, has been cleared of debris and widened and a new sign has been installed.

Note the section of the Highland Trail inside the provincial park is known locally as Higher Rim Trail.

For much more information: www.newsroom.gov.bc.ca/2013/ten/partnership-provides-local…

Okanagan’s Highland Trail gets renewed life

Image by BC Gov Images

Thanks to a multi-level partnership amongst Recreation Internet sites and Trails BC, BC Parks and the Vernon Fire Zone to improve to Okanagan’s recreation possibilities, the Highland Trail is getting upgrades to make it safer and far more accessible for residents and guests.

The very first phase of the multi-phase improvement project is now total. The trailhead, in the northeast corner of Kalamalka Lake Provincial Park at Cosens Bay Gate, has been cleared of debris and widened and a new sign has been installed.

Note the section of the Highland Trail inside the provincial park is known locally as Higher Rim Trail.

For much more information: www.newsroom.gov.bc.ca/2013/10/partnership-provides-nearby…

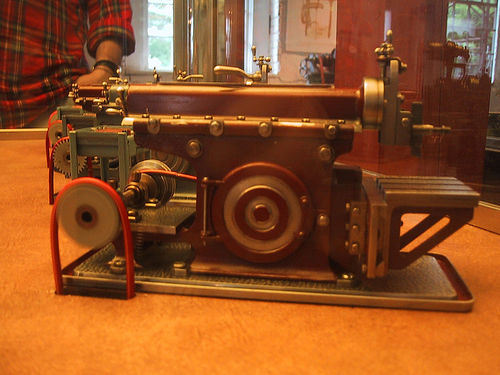

Miniature Machine

Image by jessamyn

Precision Aesthetics Renews Its Commitment to Non-Surgical Body Shaping and Non- Surgical Fat Reduction with Exilis Elite

(PRWEB) September 30, 2014

New York’s Precision Aesthetics is a distinctive health-related facility focused on the most effective non-surgical healthcare cosmetic treatments, accessible anywhere in the planet, for the face and the physique. Led by Lisa A Zdinak MD, Health-related Director, it boasts no much less than twelve technologies sourced from other countries, several of which it was the first to introduce to New York. In addition there are numerous combination protocols and proprietary methods also employed at the health-related facility. Exilis was in fact discovered at a European trade show by Dr Lisa. It was instantly recognized for its efficacy in non-surgical fat reduction and physique shaping.

Previously, Precision Aesthetics relied solely on Thermage for body shaping, loose skin and non-surgical face lifting. Nonetheless the devices are not identical, they have slightly distinct strengths. Despite the fact that each machines are capable of physique shaping, face lifting and dealing with loose skin, Exilis seems to have the edge for body shaping and non-surgical fat reduction. Soon after a lot of years of knowledge Chief Technician, Danielle Braz and Dr Lisa Zdinak have evolved each mixture protocols and special systems for deciding which patient conditions would benefit from either machine alone, or the mixture of the two. In reality Precision Aesthetics worked closely with Engineers from BTL Industries and President and Chief Engineer and CEO Jan Zarsky in building protocols for its newest upgrade known as Exilis Elite.

Precision Aesthetics is the only Thermage Black Diamond and Pinnacle Award winner for over 7 years in New York. For many years Thermage was the only device that was effectively becoming employed for non-surgical skin tightening and physique shaping. Although still a top Thermage provider, numerous New York individuals are deciding on Exilis for certain situations. Apart from physique shaping, Exilis is also much better for smaller places on the face and physique and “post lipo” lumps. Each machine has certain conditions it excels at treating that only a technician certified in utilizing both would be able to decide.

In addition to Thermage and Exilis a few of the far more well-liked offerings at Precision Aesthetics are Acoustic Wave for cellulite, Carboxytherapy for Stretch marks, and Vampire Face lift for the face.

Precision Aesthetics is positioned at ten West 74th st in a boutique style facility designed by Dr Lisa for ultimate in patient privacy and comfort. Privacy is taken very seriously. In truth due to VIP client concerns any signage indicating a Doctors workplace on the creating and on our door have been removed. For much more data go to http://www.precisionaestheticsmd.com/services-exilis-nonsurgical-fat-reduction.html