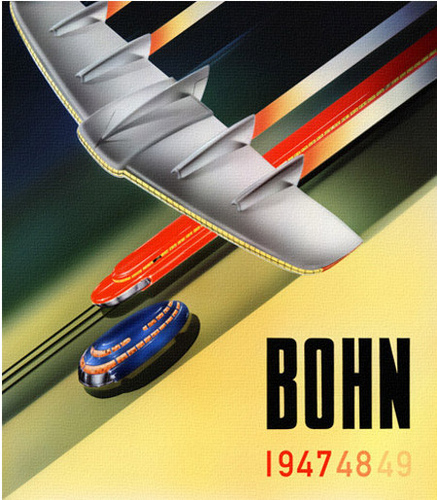

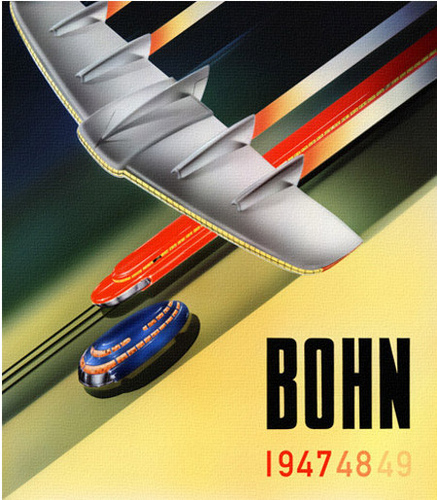

Verify out these sheet metal components china images:

Bohn Aluminum & Brass, 1947 …item three.. Alcoa Cuts Worldwide Aluminum Forecast on China Slowdown — Aluminum will typical ,212 a ton subsequent year (Thursday, 11 October 2012) …

Image by marsmet525

“We do see a slight slowdown in some regions in finish- markets, and the main driver for this is China,” Chairman and Chief Executive Officer Klaus Kleinfeld said on a conference call with analysts. Chinese demand may possibly pick up at the end of the fourth quarter because of stimulus spending, he mentioned.

.

…….***** All pictures are copyrighted by their respective authors …….

.

……………………………………………………………………………………………………………………………………………………………………….

.

…..item 1)…. Habor Aluminum … www.harboraluminum.com/ …

> aluminum industry evaluation, market outlook & forecasts

> important aluminum news & our comments free!

> aluminum other analysts views

.

.

……………………………………………………………………………………………………………………………………………………………………….

.

…..item 2)…. Reuters … www.reuters.com … Press Release

Hydro and Orkla to form the world’s major aluminium options provider

* Reuters is not responsible for the content in this press release.

Mon Oct 15, 2012 1:00am EDT

www.reuters.com/write-up/2012/ten/15/idUS33196+15-Oct-2012+…

Norsk Hydro ASA and Orkla ASA have agreed to combine their respective profiles, building systems and tubing organization, creating the world’s major aluminium solutions provider. The new combined company, to be named Sapa, will be a 50/50 joint venture owned by Hydro and Orkla.

.

.

……………………………………………………………………………………………………………………………………………………………………….

.

…..item three)…. HELLENIC SHIPPING NEWS – Worldwide … www.hellenicshippingnews.com …

On-line Day-to-day Newspaper on Hellenic and International Shipping

Tuesday, 16 October 2012 | 17:43

.

.

Alcoa Cuts Worldwide Aluminum Forecast on China Slowdown

Thursday, 11 October 2012 | 00:00

www.hellenicshippingnews.com/News.aspx?ElementId=582a442a…

Alcoa Inc. (AA), the largest U.S. aluminum producer, reduce its forecast for international consumption of the metal by 1 percentage point on slowing Chinese demand, assisting to trigger a decline in Asian stocks for a third day.

Demand will climb by 6 % this year, New York-based Alcoa stated yesterday in its third-quarter earnings statement. That is significantly less than the company’s July prediction for a 7 % improve in usage.

“We do see a slight slowdown in some regions in end- markets, and the major driver for this is China,” Chairman and Chief Executive Officer Klaus Kleinfeld said on a conference get in touch with with analysts. Chinese demand may possibly pick up at the finish of the fourth quarter simply because of stimulus spending, he mentioned.

The forecast revision by Alcoa, typically the 1st firm on the Dow Jones Industrial Average to report earnings, comes a day right after the International Monetary Fund and Rio Tinto Group, the world’s third-largest mining business, trimmed their growth outlook estimates for China. Aluminum rates in London touched a 34-month low in August as worldwide supply exceeded demand.

“The international economy is clearly slowing,” Lloyd O’Carroll, a Richmond, Virginia-primarily based analyst for Davenport & Co., stated yesterday in an interview. “That’s what the IMF stated nowadays and so I consider what Alcoa is carrying out is constant with that.”

— Shares Drop

Alcoa traded at 7.02 euros as of 9:38 a.m. in Frankfurt. That’s equivalent to .03, a 1.1 percent decline from yesterday’s closing cost in New York. The MSCI Asia Pacific Index (MXAP) slipped .9 percent at four:42 p.m. in Tokyo, whilst Aluminum Corp. of China Ltd., the nation’s biggest producer of the metal, dropped as much as 2.1 percent in Hong Kong.

Demand from heavy-truck and trailer manufacturing will fall this year, Alcoa mentioned. It now sees Chinese truck and trailer output slumping as a lot as 21 %, compared with a decline of as considerably as eight % projected 3 months ago. Chinese can and packaging development might be 8 percent, down from Alcoa’s July forecast of as a lot as 20 %.

The IMF yesterday reduce its international growth forecast and lowered its projected expansion for China, the world’s most significant aluminum user, by .two percentage point annually, to 7.8 percent this year and 8.2 % in 2013. London-primarily based Rio, which has pulled back from projects as sluggish worldwide development lowered demand for metals, yesterday lowered its estimates for China’s growth to beneath 8 %.

— Net Loss

Alcoa reported a third-quarter net loss of 3 million, or 13 cents a share, compared with net income of 2 million, or 15 cents, a year earlier as sales dropped 9.2 %. Excluding fees related to environmental remediation and the settlement of a lawsuit brought by Aluminium Bahrain BSC (ALBH), Alcoa had per-share profit of three cents. The typical of 18 estimates compiled by Bloomberg was for break-even earnings per share.

“We are clearly seeing the effect of a Chinese slowdown globally and it is indicated in Alcoa’s numbers,” said Nader Naeimi, Sydney-based head of dynamic asset allocation at AMP Capital Investors Ltd., which manages almost billion.

Alcoa reiterated that demand will boost this year in the worldwide aerospace, auto, packaging and building industries.

The business said it improved productivity across all four company units. Its rolled goods enterprise posted the highest ever right after-tax operating income and the engineered products and options segment had a record margin on earnings before interest, taxes, depreciation and amortization.

Total sales fell to .83 billion from .42 billion, beating the .56 billion typical of 10 estimates.

— Civil Suit

Alcoa settled a four-year racketeering lawsuit brought by Aluminium Bahrain, the state-owned smelter known as Alba, both organizations stated yesterday. Alba’s 2008 civil suit alleged that Alcoa bribed officials in Bahrain to charge far more for alumina. Alba stated it paid million a lot more than it must have.

Alcoa will pay Alba million in two cash installments and agree to a extended-term sales agreement, without having admitting liability. Alba said the settlement has a total value of 7 million.

Alcoa, Rio Tinto, Norway’s Norsk Hydro ASA (NHY) and closely held Zeeland Aluminum have reduce 1.21 million metric tons of production capacity because mid-2011, according information compiled by Bloomberg.

Aluminum for delivery in three months on the London Metal Exchange averaged ,950 a ton in the third quarter, 20 % less than a year earlier. It traded at ,024 a ton as of 8:47 a.m. neighborhood time.

Costs beneath ,000 may drive more production cuts, Ken Hoffman, a Bloomberg Industries analyst, stated last week.

— Decoupled Cost

Alcoa’s Kleinfeld stated that the company predicts global demand will exceed provide by 262,000 tons this year.

The aluminum cost is “decoupled” from the supply and demand “fundamentals” of the industry, and instead is getting influenced by investor concerns about the European debt crisis and the slowdown in China, he mentioned on the call.

“The macro elements are at the moment dominating the pricing scenario,” he mentioned. “But it can reverse extremely, really swiftly.”

Aluminum will typical ,212 a ton subsequent year, according to the median of 22 analyst estimates compiled by Bloomberg. The metal traded at more than ,300 in 2008 ahead of the monetary crash, and reached a 2011 intraday higher of ,803 a ton.

Alcoa is organized into four segments: alumina, which mines bauxite and processes it into the precursor to aluminum principal metals, which smelts aluminum flat-rolled products, which tends to make sheets used in beverage cans as effectively as airplane wings and vehicle parts and engineered products and options, which produces aerospace fasteners, turbine blades and truck wheels.

— Supply: Bloomberg

.

.

……………………………………………………………………………………………………………………………………………………………………….

.

.

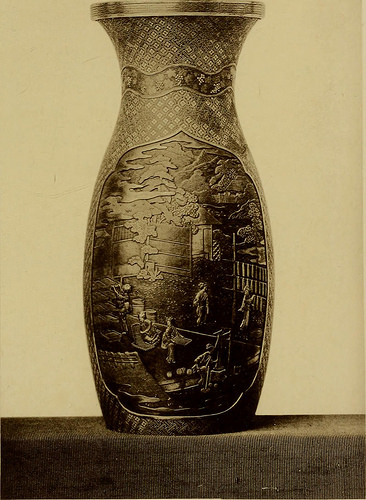

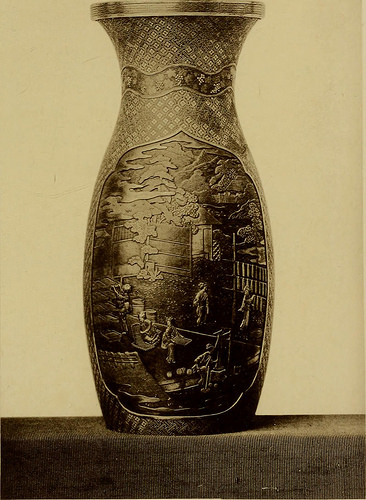

Image from web page 488 of “The industries of Japan : collectively with an account of its agriculture, forestry, arts, and commerce. From travels and researches undertaken at the expense of the Prussian government” (1889)

Image by Web Archive Book Photos

Identifier: industriesofjapa00rein

Title: The industries of Japan : with each other with an account of its agriculture, forestry, arts, and commerce. From travels and researches undertaken at the price of the Prussian government

Year: 1889 (1880s)

Authors: Rein, J. J. (Johannes Justus), 1835-1918 Rein, J. J. (Johannes Justus), 1835-1918. Japan nach Reisen und Studien. V. 2. Land- und Forstwirthschaft, Industrie und Handel. English Hodder and Stoughton, publisher

Subjects: Industries Agriculture Art, Japanese

Publisher: London : Hodder and Stoughton

View Book Page: Book Viewer

About This Book: Catalog Entry

View All Images: All Photos From Book

Click right here to view book on the internet to see this illustration in context in a browseable on the web version of this book.

Text Appearing Just before Image:

h stone weapons andcoarse earthen vessels, are also copper swords and modest roundbells (Suzu) of copper plate, and other bells (Tsuri-gane) of con-siderable size.1 Copper possibly came 1st with Buddhism fromChina and Corea to Japan. It is certain that it has served for theornamentation and outfitting of Buddhist temples and pagodas, asin India and China, in manifold types, from the very first introductionof Buddhist teaching till the present time. If it does not play in Japanese religion and in the household soprominent a portion as in India, where copper and brass vessels haveserved for ages the manifold purposes for which we, normally,use wooden, clay and glass ware, it is nonetheless in Japan oftensubstituted for the earthen vessel as well as for iron, zinc and tin.Among other beneficial copper utensils, I mention only the Yatate orportable writing-case, in which the Japanese organization man carries 1 See Kanda Takahira On some Copper Bells. Transact. As. Soc. ofJapan, vol. iv. p. 29 to 33.

Text Appearing Right after Image:

PHOTOTYPE BY STRUMPER & CO., HAMBUI INLAID VASE OF CAST-IRON.Original in the ROYAL KUNSTGEWERBE MUSEUM Berlin. METAL Business. 437 with him his brush and fluid India ink, the Kana-darai, the wash-dish of brass or copper, and the Yuwakashi or copper kettle forboiling water. Copper cannot be cast like iron and bronze, since it makesbubbles and types holes in stiffening. It is as a result worked upinto wire and sheet form. It is very considerably employed in this kind formounting fine boxes and cabinets, with holds and cramps, whichare most tastefully decorated by engraving of arabesques, flowers,birds, and other items.1 I will give right here another technique of treating copper, which hasnot yet been described anyplace else. I first became acquaintedwith it by means of the celebrated bronze manufacturer, Kanaya Goro-saburo, in Kioto. Besides several sorts of bronze ware, he makesalso tiny copper water-kettles, holding from a half to a wholeliter, in which only the revolving knob of the cover and the twosold

Note About Images

Please note that these pictures are extracted from scanned web page photos that may have been digitally enhanced for readability – coloration and look of these illustrations might not completely resemble the original function.

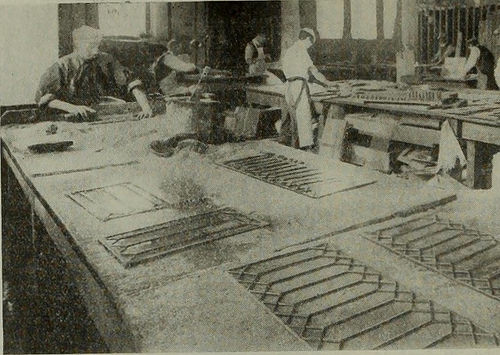

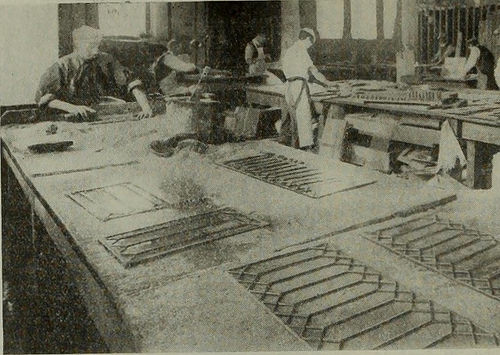

Image from web page 1065 of “Hardware merchandising January-March 1916” (1916)

Image by Net Archive Book Photos

Identifier: hardmerchjanmar1916toro

Title: Hardware merchandising January-March 1916

Year: 1916 (1910s)

Authors:

Subjects: Hardware sector Hardware Implements, utensils, and so on Developing

Publisher: Toronto :

View Book Web page: Book Viewer

About This Book: Catalog Entry

View All Photos: All Pictures From Book

Click right here to view book on the internet to see this illustration in context in a browseable online version of this book.

Text Appearing Just before Image:

ed lead is painted on.They are allowed to stay a day in thedrying area, then are cleaned with adamp cloth, rolled in paper and packedin boxes twenty to every single. Art Glass Work A extremely critical portion of the activi-ties of a big glass concern is the artglass division. Here a big stockof the various shades of glass is kept.The colored glasses are mostly all madewith the use of chemical compounds. In the rubyglass the color is obtained by mixing insome pure gold. Cobalt blue is obtainedby adding the cobalt metal. An artistdesigns all the numerous patterns. Hemakes a drawing and indicates the num-ber and shade of the glass he desires.One more man cuts the glass and arrangesthe pieces according to the specificationson the drawing. These pieces are thenlaid together on a work table with theaid of the lead frames. When the de-sign is totally laid out the lead sec-tions are soldered together and a cementrun around the glass in the frame tokeep it securely in location. Copper frames HARDWARE AND METAL

Text Appearing Following Image:

Mivi-h 18, 191! Arranging and cementing art glass designs. are used on some of the greater classes ofart frames. Several Different Kinds of GlassIn addition to the art glass, plateglass and ordinary sheet glass there arcnumerous other kinds of glass, such asthe wired plate glass, which is usedlargely in skylights, elevator fronts, fac-tory window. Ordinary chicken wirenetting is molded into the centre of theglass and prevents the glass from fall-ing out ought to it grow to be cracked. Thenthere is the prism glass for the purposeof reflecting light into the interior ofbuildings from alleyways and light wellsand other locations exactly where it is difficult toget a direct light ray. Also there arethe figured rolled glasses made in manypatterns and utilised as decorative glasses. Bending of Glass One particular of the most exciting processesin the manufacture of glass is the bend-ing of sheets to the a variety of shapes re-quired in the trade. There are the hentjilates employed in china cahinets, hook casesand cabinets of variou

Note About Pictures

Please note that these pictures are extracted from scanned web page pictures that may have been digitally enhanced for readability – coloration and look of these illustrations may not completely resemble the original perform.