A few nice milling machine parts images I found:

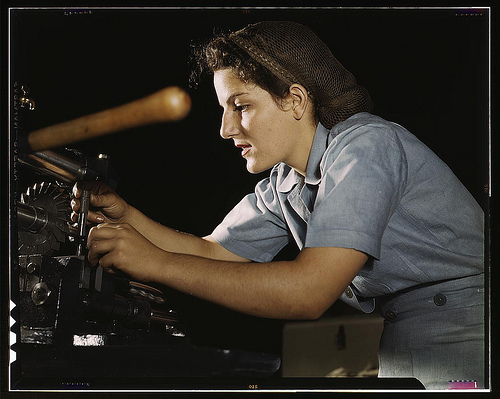

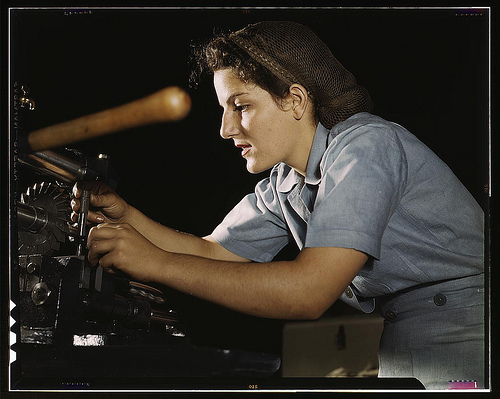

Mary Louise Stepan, 21, used to be a waitress. She has a brother in the air corps. She is working on transport parts in the hand mill, Consolidated Aircraft Corp., Fort Worth, Texas (LOC)

Image by The Library of Congress

Hollem, Howard R.,, photographer.

Mary Louise Stepan, 21, used to be a waitress. She has a brother in the air corps. She is working on transport parts in the hand mill, Consolidated Aircraft Corp., Fort Worth, Texas

1942 Oct.

1 transparency : color.

Notes:

Title from FSA or OWI agency caption.

Transfer from U.S. Office of War Information, 1944.

Subjects:

Consolidated Aircraft Corporation

Airplane industry

World War, 1939-1945

Women–Employment

United States–Texas–Fort Worth

Format: Transparencies–Color

Rights Info: No known restrictions on publication.

Repository: Library of Congress, Prints and Photographs Division, Washington, D.C. 20540 USA, hdl.loc.gov/loc.pnp/pp.print

Part Of: Farm Security Administration – Office of War Information Collection 12002-19 (DLC) 93845501

General information about the FSA/OWI Color Photographs is available at hdl.loc.gov/loc.pnp/pp.fsac

Higher resolution image is available (Persistent URL): hdl.loc.gov/loc.pnp/fsac.1a34943

Call Number: LC-USW36-292

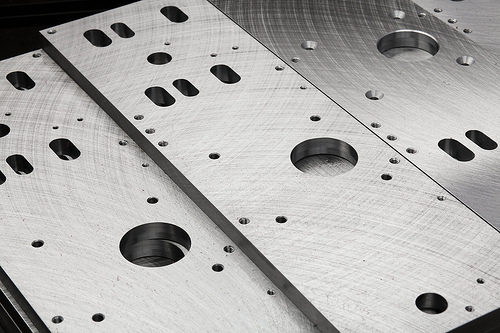

Machine Room

Image by tj.blackwell

A fantastically chaotic mess of rusting iron can be found in the mill’s old machine room, which is still populated with all manner of industrial implements from a former age. Around the fringe a grid of shelves and cupboards overflow with miscellaneous springs, sprockets, nuts, bolts and other metallic paraphernalia. The rest of the space is taken up with work benches alongside lathes, drills, clamps, vices and a variety of belt-driven units. This small room would have been, in some respects, the beating heart of the mill: continuously China manufacturing bespoke replacement parts for the looms and other equipment on the spinning floors.

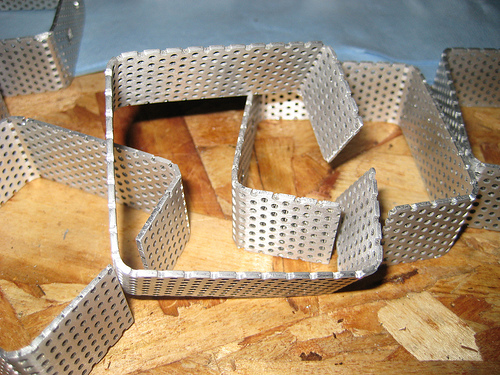

Machine Parts

Image by Theresa L Wysocki

Watkins Woolen Mill.

![James Brown – Get Up I Feel Like Being a Sex China Machine (Single Version) [Parts 1 & 2] James Brown – Get Up I Feel Like Being a Sex China Machine (Single Version) [Parts 1 & 2]](http://www.precisiontype.com/blog/wp-content/uploads/2014/08/dj.sfugrjop.60x60-50.jpg)