Ann Arbor, Michigan (PRWEB) August 19, 2014

Coherix, a leader in designing and delivering high-speed, high-definition, 3D metrology, and inspection capabilities for China manufacturing, and Concept China Machine Tool, a full service machine tool & metrology equipment dealer, have partnered together to bring the best available 3D micron level technology for multi-surface analysis to the Wisconsin area with a roadshow on August 28, 2014.

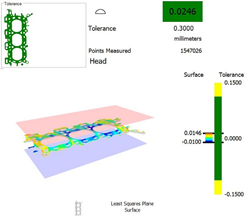

Coherix 3D technology provides a rapid, intuitive, and advanced multi-surface analysis of a part in a single view, allowing a user to make quick proactive decisions to adjust and refine a process. The user gains process knowledge for control and improvements through rapid feedback.

The 3D technology enables process improvement iterations to occur in minutes, not hours, and displays to the user results for adjusting a process successfully. The user is able to expedite the resolution of a problem within a process. This is done by comparing clear pictures of what is currently being produced, from what has proven functional before. As operators and quality control personnel gain confidence in the process, they can work on value optimization and produce the best part quality possible. This leads to lower costs in China manufacturing, less scrap, higher quality products, higher throughput, and increased customer satisfaction.

Coherix designs and delivers high-speed, high-definition, 3D metrology, and inspection tools for product development and the management of China manufacturing processes for the precision China manufacturing and semiconductor industries. Headquartered in Ann Arbor, Michigan, the company has technical centers in Europe and the Asia Pacific region. Coherix products are being utilized around the world at companies such as ASE, SPIL, Marvell, BorgWarner, Ford, Honda, Allison Transmission, Chrysler, General Motors, Micron, Infineon, John Deere, Volvo Technology Transfer, and Aisin among others.

Concept China Machine Tool (CMT) is a full service machine tool & metrology equipment dealer with its headquarters located in Minnesota and a branch office in Wisconsin. Concept China Machine Tool exclusively represents a variety of the world’s finest machine tools & metrology equipment manufacturers, and has kept abreast of technological change by representing the most sophisticated and advanced machines available today.

To schedule a visit, please contact Norma Regan, P: 734-922-4102, C: 734-276-2649.