Charlotte, NC (PRWEB) September 25, 2014

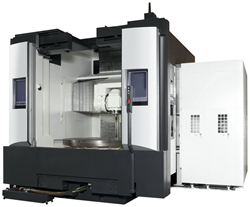

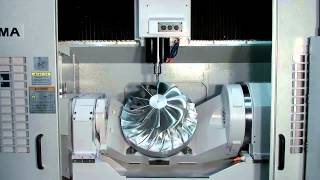

Okuma introduced its new V760EX vertical lathe, an update to the well-known V60R model at IMTS 2014. This new version offers a bigger operate envelope in the very same footprint, permitting for an further 110mm in workpiece height and an added 150mm maximum turning diameter. It gives stable, higher-precision cutting in a little footprint and is an excellent platform for machining thin and odd-shaped function pieces, and is properly suited for the oil and gas and aerospace industries.

The V760EX vertical lathe has effective cutting capabilities, a class major functioning range, and exceptional ergonomics. The box way method and rock strong base and column give a very reliable, hugely rigid structure. The headstock has flange building such as precision, hand-scraped mounting surfaces. This minimizes the effects of thermal deformation and vibration, guaranteeing stable, precise cutting.

This machine’s ergonomic design and style consists of straightforward access to the chuck and a front-skirt operation panel, delivering comfort for up-close jobs.

Key Specs of the V760EX Vertical Lathe

Max Turning Diameter, mm (in) Ø 760 (Ø )

Spindle Nose Sort, JIS A2-11

Speed Range, min⁻¹ 20~two,000

Energy 30 min, kW (hp) 30 (40)

Energy cont., kW (hp) 22 (30)

Fast Traverse (X/Z), m/min (ipm) 24/24 (945/945)

For much more details on Okuma’s V760EX visit http://www.okuma.com/v760ex.

About Okuma America Corporation

Okuma America Corporation is the U.S.-primarily based sales and service affiliate of Okuma Corporation, a planet leader in CNC (computer numeric handle) machine tools, founded in 1898 in Nagoya, Japan. The business is the industry’s only single-source provider, with the CNC machine, drive, motors, encoders, spindle and CNC manage all manufactured by Okuma. Okuma’s innovative and reliable technology, paired with comprehensive, localized service protection, makes it possible for users to run continuously with self-assurance – maximizing profitability. Along with its industry-leading distribution network (largest in the Americas), and Partners in THINC, Okuma facilitates top quality, productivity and efficiency, empowering the buyer and enabling competitive advantage in today’s demanding manufacturing environment. For much more details, check out http://www.okuma.com or stick to us on Facebook or Twitter @OkumaAmerica.

About Partners in THINC

Partners in THINC is a collaboration network of more than 40 market leaders who come collectively to resolve difficulties and explore new productivity concepts for real-world producers. With the open architecture, Pc-based THINC®-OSP handle as its nucleus, Partners in THINC brings specialized gear, expertise and a commitment to provide the very best achievable integrated solutions to the end-user. For far more information, check out http://www.okuma.com/partners-in-thinc.

###