A few nice component manufacturing company images I found:

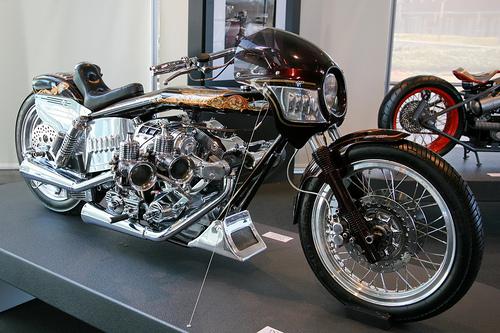

Hotchkiss 864 (1937)

Image by pedrosimoes7

Cascais, Portugal

in Wikipedia

Hotchkiss cars were made between 1903 and 1955 by the French company Hotchkiss et Cie in Saint-Denis, Paris. The badge for the marque showed a pair of crossed cannons, evoking the company’s history as an arms manufacturer.

The company’s first entry into car making came from orders for engine components such as crankshafts which were supplied to Panhard et Levassor, De Dion-Bouton and other pioneering companies and in 1903 they went on to make complete engines. Encouraged by two major car distributors, Mann and Overton of London and Fournier of Paris, Hotchkiss decided to start making their own range of cars and purchased a Mercedes Simplex for inspiration and Georges Terasse, previously of Mors, was taken on as designer.

Early cars

The first Hotchkiss car, a 17 CV four-cylinder model, appeared in 1903. The engine of the 20 CV type C was heavily based on the Mercedes Simplex except that wherever possible it used ball bearings rather than plain ones (including the crankshaft) and except the Hotchkiss drive. Six-cylinder models, the types L and O followed in 1907.

The ball bearing engines lasted until the 30CV type X of 1910. In that same year Hotchkiss moved into a smaller car market with the 2212cc type Z.

With the outbreak of World War I, the factory turned to war production and a subsidiary plant was opened in Coventry, England. Car production resumed in France 1919 with the pre war types AD, AD6, AF and AG.

Inter war production

After an attempt to enter the luxury market with the AK, which did not get beyond the prototype stage, the company decided on a one model policy and introduced the Coventry designed AM in 1923. Later that year the Coventry plant was sold to Morris. Henry Ainsworth (1884–1971) and A.H. Wilde who had run it, moved to Paris to become general manager and chief engineer of the car division respectively.

In 1926 construction of the new factory in the Boulevard Ornano was completed and Hotchkiss bought a steel pressing company allowing in-house manufacture of bodies. The one model policy lasted until 1929 when the six-cylinder AM73 and AM80 models were announced.

The AM models were replaced by a new range in 1933 with a new naming system. The 411 was an 11CV model with four-cylinder engine, the 413 a 13CV four and the 615, 617 and 620 were similar six-cylinder types. The 1936 686, which replaced the 620, was available as the high-performance Grand Sport and 1937 Paris-Nice with twin carburettors and these allowed Hotchkiss to win the Monte Carlo Rally in 1932, 1933, 1934, 1939, 1949 and 1950.

Second World War

The armament side of the company and the body stamping plant were nationalised in 1936 by the Front Populaire government. The car company in 1937 took over Amilcar. With re-armament speeding up they also started making military vehicles and light tanks. When France declared war, in September 1939, Hotchkiss were sitting on a army order for 1,900 H35 and H39 tanks powered by six-cylinder motors of respectively 3.5 and 6 litres capacity, and at the time of the German invasion in May 1940 they were still working through the order.[1] However, as the military situation deteriorated the decision was taken, on 20 May 1940, to abandon the Saint-Denis plant which by now was fully concentrated on war production.[1] There was a disorderly evacuation, initially towards Auxerre and then Moulins and then further towards the south, as employees desperately tried to keep information on the military production out of the hands of the Germans.[1] However, the national capitulation implicit in the signing of the armistice on 22 June left these efforts looking somewhat irrelevant, and most of the employees drifted back in the ensuing weeks.[1] Two exceptions were the Commercial Director, Jacques Jacobsen and the English born General Director, Henry Ainsworth, both of whom managed to avoid capture and to leave France.[1] During the war, like many businesses in the occupied (northern) zone, the company was obliged to work for the occupiers and was engaged in the repair of military vehicles.[1]

In 1941 François Lehideux, then a leading member of the government’s economic team, called Jean-Pierre Peugeot and his General Director Maurice Jordan to a meeting, and invited them to study the possibility of taking a controlling share in the Hotchkiss business.[1] The suggestion from Lehideux derived from a German law dated 18 October 1940 authorising the confiscation of businesses controlled by Jews.[1] The Peugeot business itself had been operating, grugingly, under overall German control since the summer of 1940. In any event, in July 1942 Peugeot took a controlling share in the Hotchkiss business and towards the end of 1942 the names of Peugeot and Jordan were listed as members of the Hotchkiss board.[1] There is no evidence of any attempt to combine the operations of the two businesses, however: after the war Peugeot would relinquish their holding in Hotchkiss.

With liberation in 1944, Ainsworth returned and production restarted in 1946 with the pre-war cars, a light truck and a tractor.

Post war models

1955 Hotchkiss Anjou

After the war, car production resumed only slowly with fewer than 100 cars produced in each of 1946 and 1947, but by 1948 things were moving a little more rapidly with 460 Hotchkiss cars produced that year.[2] This volume of output was wholly insufficient to carry the company, although truck production was a little more successful with more than 2,300 produced in 1948,[2] and it was support from the truck volumes and from the Jeep based M201 that enabled the company to stagger on as a car producer slightly more convincingly than some of France’s other luxury car makers, at least until the mid 1950s. The cars that represented the business in the second half of the 1940s were essentially the company’s prewar designs. The 2,312 cc four-cylinder car was now branded as the Hotchkiss 864 while the six-cylinder car was badged as the Hotchkiss 680 with a 3,016 cc engine or as the Hotchkiss 686 with the 3,485 cc engine.[2]

The automobile range was modernised in 1950 and a new car, the four-door saloon Anjou, was available on the 1350 (renamed from the 486) and 2050 (686) chassis. The Anthéor cabriolet was added in 1952. In 1948 Hotchkiss had bought the rights to the Grégoire front-wheel-drive car and this car entered production in 1951 but was expensive. Sales in general were falling and in 1950 Ainsworth retired. The Peugeot family sold their interest in the company. Coupé and cabriolet versions of the Hotchkiss-Grégoire were announced in 1951, but sales did not improve, and production stopped in 1952 after only 247 were made.

Merger and closure

Hotchkiss merged with Delahaye in 1954 to become Société Hotchkiss-Delahaye, but car production stopped in 1955 to be replaced by licence built Jeeps. In 1956 the company was taken over by Brandt, a household appliance maker, to become Hotchkiss-Brandt, who were again taken over in 1966 by Thomson-Houston. Military vehicles were made until 1967 and trucks until 1971.

[edit]

FROM PLANET EARTH

Image by jurvetson

On July 16, 1969, Apollo 11 took flight to the moon. In the days that preceded the launch, the U.S. scrambled to pull together the messages from Earth that would be left behind on the moon. This is the Apollo Goodwill Disc, and it was engineered to last long after the U.S. flag was destroyed.

This silicon disc contains etched letters (scanned and reduced 200x) from the leaders of the world’s nations. This is one of the discs produced by Sprague and retained by a Sprague manager; a second resides in the Smithsonian, and a third rests on the Moon’s Sea of Tranquility, deposited there by Buzz Aldrin.

(Does anyone know if other builds remain intact? A Sprague press release says that of the handful of discs made, one was given to President Nixon and one to President Johnson).

It is a tricky subject matter for photography. I wanted to capture the angle-dependendent iridescence of the semiconductor thin films. The overhead light source reflects off the leather seat cushion, revealing the shift from green to purple that occurs at oblique angles.

This comes from the early days of the semiconductor industry, when Apollo consumed 50% of global production, and wafers were just 2” wide (the ultimate disc was cropped around the 1.5” metallized ring and placed in a aluminum case).

The concept of using lithographic thin films to create a long-term alternative to microfiche was novel at the time, earning Sprague a patent (#3,607,347). I used those techniques to create a multi-colored Devo hat on a chip I designed at HP in 1988.

The story of the rushed creation of the disc is fascinating, as are the messages embedded in this interplanetary time capsule.

The concept started in June, 1969, and it was a politically charged project, in the midst of the Cold War and the Vietnam War. On June 27, NASA telephoned the state department, and got the unprecedented permission to contact the foreign chiefs of state to deposit a message on the moon. This was 19 days before launch. They were asked to compose and send typed and scribed letters to the U.S. (they came by telegram and mail).

But NASA did not know how they would store the messages so that they could last thousands of years in the harsh temperatures, solar radiation, and cosmic rays on the lunar surface. So they approached the supplier of some of the most advanced technology on Apollo – the nascent semiconductor industry.

Sprague manufactured 53,000 components on the Apollo 11 spacecraft and many more for the ground support equipment. The engineers chose silicon for the storage medium because of the density of storage and the stability of silicon over temperature in a vacuum.

“Crash course is an understatement. We had almost no time to put this together!”

— John Sprague, head of the semiconductor division

NASA officials delivered the goodwill letters on the July 4 holiday, and Sprague finished the first printing on July 5 at 3 a.m. Each letter was photographed, and optically reduced to the point where each letter was ¼ the width of a hair. The image was transferred to a glass photomask which was then used to image the silicon, much like the early days of IC manufacturing.

“It was a rush to get it done. We slept on lab benches for two days in a row.”

— Ray Carswell, Sprague Engineer

However, on July 9, the company was asked to start over and create a new disc with eight additional messages. It was completed and sent to Houston at 3:30 a.m. on July 11, five days before launch.

In the comments below are some of the messages that caught my eye, including the Vatican and Estonia (recognized despite their Soviet occupation at the time).

The letters were written independently at a historic epoch in exploration abroad and conflict at home. Most of them reference God or peace on Earth.

“The Silicon disc represents a historic time when many nations looked beyond their differences to come together to achieve this historic first.”

— Charlie Duke, Apollo 16 moonwalker

Steven F. Udvar-Hazy Center: X-35B Joint Strike Fighter, A-6E Intruder, F-4S Phantom II, Sikorsky UH-34D Seahorse, UH-1H Iroquois “Huey” Smokey III, F-105D Thunderchief, F4U-1D Corsair, P-40E, SR-71 Blackbird, et al

Image by Chris Devers

Quoting Smithsonian National Air and Space Museum | Lockheed Martin X-35B STOVL:

This aircraft is the first X-35 ever built. It was originally the X-35A and was modified to include the lift-fan engine for testing of the STOVL concept. Among its many test records, this aircraft was the first in history to achieve a short takeoff, level supersonic dash, and vertical landing in a single flight. It is also the first aircraft to fly using a shaft-driven lift-fan propulsion system. The X-35B flight test program was one of the shortest, most effective in history, lasting from June 23, 2001 to August 6, 2001.

The lift-fan propulsion system is now displayed next to the X-35B at the Steven F. Udvar-Hazy Center near Dulles Airport.

On July 7, 2006, the production model F-35 was officially named F-35 Lightning II by T. Michael Moseley, Chief of Staff USAF.

Transferred from the United States Air Force.

Date:

2001

Dimensions:

Wing span: 10.05 m (33 ft 0 in)

Length: 15.47 m (50 ft 9 in)

Height: approximately 5 m (15 ft 0 in)

Weight: approximately 35,000 lb.

Materials:

Composite material aircraft skin, alternating steel and titanium spars. Single-engine, single-seat configuration includes lift-fan and steering bars for vertical flight.

Physical Description:

Short takeoff/vertical landing variant to be used by U.S. Air Force, U.S. Marines and the United Kingdom, equipped with a shaft-driven lift fan propulsion system which enables the aircraft to take off from a short runway or small aircraft carrier and to land vertically.

Engine: Pratt & Whitney JSF 119-PW-611 turbofan deflects thrust downward for short takeoff/vertical landing capability. The Air Force and Navy versions use a thrust-vectoring exhaust nozzle. The Marine Corps and Royal Air Force/Navy version has a swivel-duct nozzle; an engine-driven fan behind the cockpit and air-reaction control valves in the wings to provide stability at low speeds.

Other major subcontractors are Rolls Royce and BAE.

• • • • •

Quoting Smithsonian National Air and Space Museum | Grumman A-6E Intruder:

The Navy’s experience in the Korean War showed the need for a new long-range strike aircraft with high subsonic performance at very low altitude–an aircraft that could penetrate enemy defenses and find and destroy small targets in any weather. The Grumman A-6 Intruder was designed with these needs in mind. The Intruder first flew in 1960 and was delivered to the Navy in 1963 and the Marine Corps in 1964.

The Navy accepted this airplane as an "A" model in 1968. It served under harsh combat conditions in the skies over Vietnam and is a veteran of the 1991 Desert Storm campaign, when it flew missions during the first 72 hours of the war. It has accumulated more than 7,500 flying hours, over 6,500 landings, 767 carrier landings, and 712 catapult launches.

Transferred from the United States Navy, Office of the Secretary

Date:

1960

Country of Origin:

United States of America

Dimensions:

Overall: 16ft 2in. x 52ft 12in. x 54ft 9in., 26745.8lb. (4.928m x 16.154m x 16.688m, 12131.8kg)

Materials:

Conventional all-metal, graphite/epoxy wing (retrofit), aluminium control surfaces, titanium high-strength fittings (wing-fold).

Physical Description:

Dual place (side by side), twin-engine, all-weather attack aircraft; multiple variants.

• • • • •

Quoting Smithsonian National Air and Space Museum | McDonnell F-4S Phantom II:

The U.S. Air Force, Navy, and Marine Corps and the air forces of 12 other nations have flown the multi-role Phantom II. In this aircraft, then a Navy F-4J, on June 21, 1972, Cmdr. S. C. Flynn and his radar intercept officer, Lt. W. H. John, spotted three enemy MiG fighters off the coast of Vietnam and shot down one MiG-21 with a Sidewinder air-to-air missile. This Phantom also flew combat air patrols and bombing missions during the Linebacker II bombing campaign that same year.

Later assigned to the Marine Corps, this F-4J was extensively modernized and designated an F-4S. Changes included improving the engines (smokeless), hydraulics, electronics, and wiring; modifying the wings to increase maneuverability; and adding a radar homing and warning antenna, as well as formation tape lights on the fuselage and vertical tail.

Transferred from the United States Navy.

Manufacturer:

McDonnell Douglas Corporation

Date:

1958

Country of Origin:

United States of America

Dimensions:

Overall: 16ft 3in. x 38ft 5in. x 58ft 3in., 39999.6lb. (4.953m x 11.709m x 17.755m, 18143.7kg)

Other: 58ft 3in. x 16ft 3in. x 38ft 5in. (17.755m x 4.953m x 11.709m)

Materials:

All metal, semi-monocoque structure

Physical Description:

Twin-turbojet (J79-GE-8), two-seat (tandem) fighter / bomber. All metal, semi-monocoque structure. Cantilever, low-wing, monoplane. Dog-toothed leading edge of wing (12 degrees), anhedral tail (23 degrees).

• • • • •

Quoting Smithsonian National Air and Space Museum | Republic F-105D Thunderchief :

The F-105 was designed as a supersonic, single-seat, fighter-bomber capable of carrying nuclear weapons or heavy bomb loads at supersonic speeds. The F-105D variant was an all-weather fighter-bomber version, fitted with mono-pulse and Doppler radar for night or bad weather operations. The original weapons bay, designed for nuclear stores, was sealed and fitted with additional fuel tanks. Bombs were carried on multiple weapons racks on the centerline of the fuselage, and on wing pylons. The aircraft was fitted with a retractable in-flight refueling probe. The first F-105D flew on 9 June 1959 and 610 F-105Ds were eventually built.

This aircraft has served in several F-105 units around the world and is restored to its 1967 Vietnam-era 388th Tactical Fighter Wing, 421st Tactical Fighter Squadron camouflage as it flew during its assignment to Korat RTAB, Thailand. This jet also was briefly assigned to the 355 TFW located at Takhli RTAB in 1968. After this "Thud" finished its combat tour-which certainly included missions supporting Operation "Rolling Thunder," "Steel Tiger," and "Barrel Roll"-it returned stateside and began more than a decade assigned to the District of Columbia Air National Guard and was transferred to the Air and Space Museum in late 1981.

Transferred from the United States Air Force.

Manufacturer:

Republic Aviation Corporation

Date:

1961

Country of Origin:

United States of America

Dimensions:

Overall: 19ft 8in., 26854.8lb. (5.994m, 12181.2kg)

Other: 19ft 8in. x 64ft 5in. x 34ft 11in. (5.994m x 19.634m x 10.642m)

Materials:

All metal monoplane, supersonic single-engine jet fighter.

Physical Description:

Single-seat, single-engine, jet, fighter/bomber; USAF.

• • • • •

Beginning in 1962, the H-34 served as the primary Marine Corps assault helicopter of the Vietnam War until its replacement by the turbine-powered CH-46. It began in 1952 as a Navy anti-submarine warfare helicopter evolved from the Sikorsky S-55 series. Initially designated as the HSS-1, it would also go on to see significant service in the combat assault and utility roles with the Army and Marine Corps. Great Britain and France also deployed versions in some of the first helicopter combat assault operations.

A large payload capacity and generous center-of-gravity range made the H-34 series an effective transport helicopter for the1950s. Its weaknesses were a reciprocating engine that struggled in the heat and humidity of Southeast Asia and maintenance intensive mechanical components. This Marine Corps UH-34D never served overseas, but wears the markings of Marine Medium Helicopter Squadron 163 that did see extensive combat in Vietnam.

Transferred from the United States Marine Corps

Manufacturer:

Sikorsky Aircraft

Country of Origin:

United States of America

Physical Description:

All equipment that came with the helicopter that is not attached to it is contained in box A19750823002 with the exception of two items. The VIP steps that attach to the side of the aircraft and the long-handled tool to assist with main rotor blade deployment are stored inside the helicopter’s cabin.

• • • • •

Quoting Smithsonian National Air and Space Museum | Bell UH-1H Iroquois "Huey" Smokey III:

In 1956, the Iroquois, commonly known as the Huey, first flew as an Army replacement for the H-13 medevac helicopter of Korean War fame. By the end of the 20th century, Bell had produced more Hueys than any other American military aircraft, except for the Consolidated B-24. Superbly suited to the air mobility and medical evacuation missions in Vietnam, the Huey became an indelible symbol of that conflict.

This UH-1 compiled a distinguished combat record in Vietnam from 1966 to 1970 with four units, including the 229th Assault Helicopter Battalion of the 1st Cavalry and the 118th and 128th Assault Helicopter Companies. Numerous patches on its skin attest to the ferocity of missions flown while operating as a "Smoke Ship," laying down smokescreens for air assault operations with the 11th Combat Aviation Battalion.

Transferred from the United States Army Aviation Museum

Manufacturer:

Bell Helicopter Company

Date:

1966

Country of Origin:

United States of America

Dimensions:

Rotor Diameter: 14.7 m (48 ft 3 in)

Length: 12.6 m (41 ft 5 in)

Height: 4.2 m (13 ft 7 in)

Weight, empty: 2,580 kg (5,687 lb)

Weight, gross: 4,309 kg (9,500 lb)

Materials:

Overall: Metal airframe, plexiglass windows.

Physical Description:

Utility helicopter, two-blade main and tail rotors, powered by a single GE T-53L13BA turbo-shaft engine. There are oil stains on the lower aft fuselage and beneath the tail rotor gear box. The horizontal stabilizer was removed.