When making metal prototypes, each precision and speed are crucial. You want to make positive that you make these prototypes as precise as achievable so that you do not risk damaging your machinery when you attempt them out. You also want to make positive that you get your prototypes accomplished as swiftly as possible so that you dont waste worthwhile time waiting for finished prototypes to try out. It is vital to your production to stay as efficient as achievable, and testing out new components can be a huge part of that. Thankfully, it is achievable to get a fast prototype made of a metal portion.

The technologies that tends to make a rapid prototype possible is a method known as additive manufacturing. In the past, metal prototypes took a extended time to make due to the fact they either needed to be cast in molds or formed out of a solid chunk of metal. It requires time to make a mold, and even longer to shave hard metal into the correct shape. But additive manufacturing permits you to swiftly form metal prototypes to precise specifications by taking a diverse approach to manufacturing prototypes. As an alternative of taking away from your raw material in order to form the prototype, it adds thin layers of material together to type the prototype.

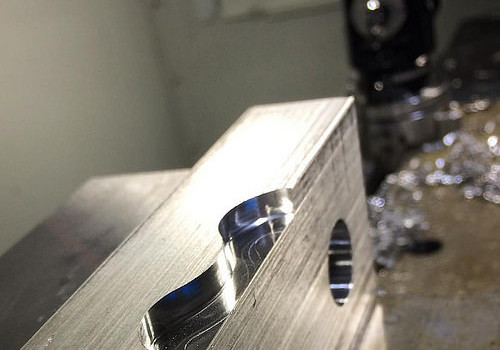

Laser sintering, also identified as direct metal laser sintering, or DMLS, entails making use of lasers to quickly heat twenty-micron layers of powdered metal collectively in order to type metal prototypes. Due to the fact the layers are so thin, you can add them progressively and still get a minute amount of detail. The precision of this technique is actually much far better than you would get attempting to create a hasty mold for a new part, and it also saves you from wasting your income making molds for components that do not work out. This is but an additional advantage of obtaining a rapid prototype produced.

And as soon as you find a speedy prototype that functions, you can just make a mold of the prototype and then cast components based on the prototype. Simply because metal prototypes formed by this strategy are so accurate, the components you cast from the mold of the original prototype are accurate, as well. This cuts down on the time it requires to go from prototype to working element, and time is cash, as they say. The more rapidly you are capable to incorporate your new, a lot more effective component into the day-to-day of your production, the more profit you will see.

Pay a visit to http://www.directedMFG.com for far more information regarding why this business is one particular of the best speedy prototype businesses in the globe. As a premier speedy prototypes company, DirectedMFG continues to provide its customers with goods and services that meet and exceed expectations. Speak to DirectedMFG these days by calling 714-546-1113.

Uncover Far more China Prototypes Articles