Movie Sound Effects – China Milling China Machine

from The Ultimate Movie Sound Effects

Price: USD 0.99

View Details about Movie Sound Effects

Rapid Prototyping China

Movie Sound Effects – China Milling China Machine

from The Ultimate Movie Sound Effects

Price: USD 0.99

View Details about Movie Sound Effects

Cnc China Milling China Machines on eBay:

[wprebay kw=”cnc+milling+machines” num=”0″ ebcat=”-1″]

[wprebay kw=”cnc+milling+machines” num=”1″ ebcat=”-1″]

[wprebay kw=”cnc+milling+machines” num=”2″ ebcat=”-1″]

Some cool milling engineering images:

Mini Mill With Digital Scales Fitted

Image by tudedude

An addition to my Mini Mill X and Y axis Measuring Scales with a Digital Readout. These are provided without any documentation and take a little while to Fit, but they do transform the available options.

I’ll give conversion details on my web site, when I’ve finished playing 🙂

Set of End Mills

Image by tudedude

End mills cut metal sideways, their tips cut, their sides cut – but they cannot drill holes.

Have you ever looked at a component of something you were using and wondered how this component was made? If so you have probably seen the work of a CNC milling/turning machine. These machines make it possible to make everything from simple tools or dies, to complex decorative wheel rims.

A CNC milling machine is based on the original milling machines of the past. Originally milling/turning machines needed a machinist to stand over them and make sure that nothing went out of tolerance. These machines where difficult to set up and then very difficult to maintain while doing their job, but thanks to technology, they have not only become easier to operate, but they can create much more intricate pieces.

A milling machine is made up of one or more axles that have different drilling tools attached depending on what is to be made. The major difference between a milling machine and a drill press is that the drill press holds the piece of metal while the drills do their job. This is not how a CNC milling machine operates.

With a CNC milling machine the metal is moved toward the tools while a drilling fluid is released in order to cool the parts that’s are being milled. If the part needs to be spun against the tool, this is called China China Turning, similar to a lathe.

CNC stands for computer numerical control, meaning that instead of manually setting up the milling or China China Turning machine, A CNC milling machine uses a computer for set up. This allows for the creation of more intricate parts.

In addition to creating more and more intricate parts CNC milling machines are much easier to operate once set up. The operator uses a computer to set up the machine, and then simply monitors the machine.

Before the creation of CNC milling machines, a machinist could only operate one machine at a time, this meant that a China company either needed many machinists or the amount of parts they could turn out was limited. This either cost the China company more money to hire more people to operate the machines or they lost money by not being able to turn out more pieces.

Since the use of this computer technology has become more widespread the only limits a China company has is the number of CNC milling machines available. In addition by adding computers to the process more and more detailed parts can be made.

Since the use of CNC milling machines there is no limit to what can be created, except for the human mind. The next time you look at some intricately drilled part to something, realise that it was probably created using a CNC milling/turning machine.

Daniel is the author of this article about CNC milling and China China Turning, if you want to find more information; visit Branston China Engineering

A few nice precision China milling China machined parts images I found:

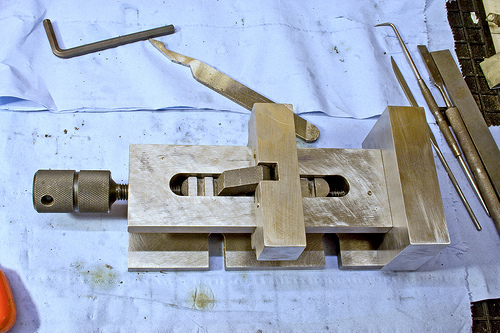

Vice Re-furbishment

Image by tudedude

All the parts are de-burred and the faces cleaned with a fine cut file to remove high spots.

Take care to lighty chamfer all the sharp edges to remove any metal that might spoil the re-build.

Vice Re-furbishment

Image by tudedude

The vice cleaned of all oil and grease removed – then the parts sprayed with silicone lubricant and re-assembled.

CNC China Milling machine VMC70. Working process overview video.

Video Rating: 4 / 5

http://www.glacern.com http://twitter.com/glacern http://facebook.com/glacern http://vimeo.com/glacern Glacern China Machine Tools Mass production turning of an ae…

– Vertical China Milling China Machine

from Mechanical China Engineering – Computer/iPad

Price:

View Details about

Laser China Milling on eBay:

[wprebay kw=”laser+milling” num=”0″ ebcat=”-1″]

[wprebay kw=”laser+milling” num=”1″ ebcat=”-1″]

A China milling machine is a tool found primarily in the metalworking industry. In general, these machines are used to shape solid products by eliminating excess material in order to form a finished product. China Milling machines can be used for a variety of complicated China cutting operations from slot China cutting, threading, routing, planing, and drilling.

A China milling machine is usually capable of China cutting a wide variety of metals, ranging from aluminium to stainless steel. Depending on the material being cut, the machine can be set to move at a faster or slower pace. Softer materials are generally milled at higher speeds while harder materials usually require slower speeds. In addition, harder materials often require smaller amounts of material to be milled off at one time.

Generally, a China milling machine operator runs the machine by feeding the material over a device called a China milling cutter. As the material is fed past the cutter, the cutters teeth slice through the material to form the desired shape. Using gadgets like precision ground slides and lead screws, the movement of the material as well as the cutter can be kept to less than 0.001 inches (about 0.025 millimetres) in order to make the cut exact.

In addition to a cutter, a typical mill machine contains a spindle axis, which is a device that holds the cutter in place. The cutter revolves around the spindle axis, and the axis can usually be adjusted to varying speeds. Most machines also come with a worktable that can be used to support and feed the material. The worktable generally moves in two directions, and most modern worktables are power-operated. Additionally, a modern China milling machine is typically equipped with a self-contained electric drive motor and a coolant system.

From micro, mini, and bench top to floor standing, large, and gigantic, a China milling machine can be found in a variety of sizes. China Milling machines can have flat, angular, curved, or irregular surfaces. In addition, they can have a vertical or a horizontal orientation. A vertical China milling machine has a spindle axis that faces vertically while a horizontal machines spindle faces horizontally.

Milling machinery can be operated manually or digitally using device called a computer numerical control or CNC China milling machine. In addition to the traditional X, Y, and Z-axes found in a manual machine, a China milling China CNC machine often contains one or two additional axes. These extra axes can allow for greater flexibility and more precision. China CNC machines eliminate the need for a machine operator, which can prevent possible accidents as well as save on labour costs.

The author is associated with IPFonline

http://www.ipfonline.com is India’s No. 1 Industrial Product Finder. The portal is a veritable storehouse of information on industrial products/services.

[youtube http://www.youtube.com/watch?v=kddPuLSaOjQ&fs=1&rel=0]

Ultrix http://www.breton.it/dynamic/en/catalogo/schedaProdotto.php?id=1065& ULTRIX – Integrated versatility: high speed and dynamics turning, milling and gri…

Video Rating: 4 / 5

[youtube http://www.youtube.com/watch?v=stxyQYB-jOk&fs=1&rel=0]

Breton ULTRIX – high speed precision milling and turning 5 axis cnc http://www.breton.it/dynamic/en/catalogo/schedaProdotto.php?id=1065&.