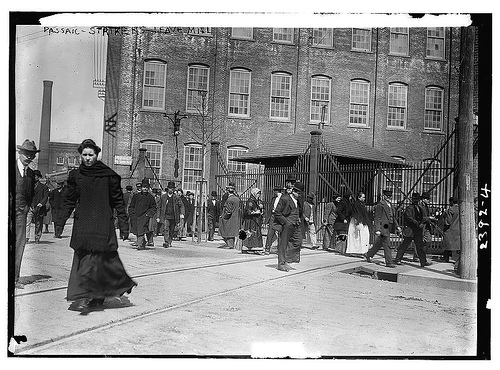

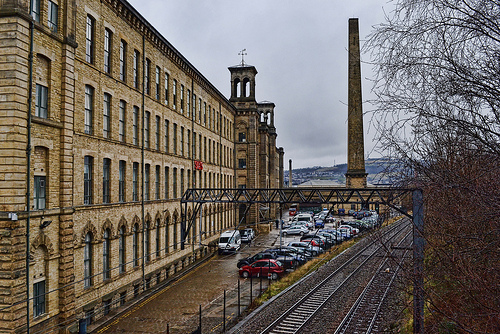

A couple of good milling and machining photos I identified:

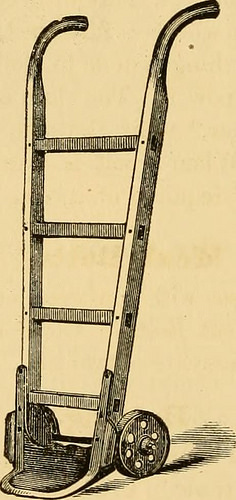

Image from page 107 of “Descriptive pamphlet of the Richmond Mill Furnishing Operates: all sizes of mill stones and complete grinding and bolting combined husk or transportable flouring mills, transportable corn and feed mills smut and separating machines zigzag and

Image by Internet Archive Book Photos

Identifier: descriptivepamph00rich

Title: Descriptive pamphlet of the Richmond Mill Furnishing Operates: all sizes of mill stones and full grinding and bolting combined husk or transportable flouring mills, transportable corn and feed mills smut and separating machines zigzag and oat separators, dustless separators, warehouse separators, water wheels mill shafting pulleys spur and bevel, iron and core, gearing ..

Year: 1873 (1870s)

Authors: Richmond Mill Furnishing Works. [from old catalog]

Subjects: Nordyke, Marmon & Company Flour industry Milling machinery Mills and mill-operate

Publisher: Richmond, Ind., Telegram Steam Print. Co.

View Book Web page: Book Viewer

About This Book: Catalog Entry

View All Pictures: All Pictures From Book

Click right here to view book online to see this illustration in context in a browseable on-line version of this book.

Text Appearing Prior to Image:

a lightcup, and providing the least resistance in passing via the grain ofany cup now provided. They are less liable to catch on the sides of the Elevator trunking,and no breaking and tearing as is frequent to the cheap wired or roughiron cups sacured to the belt in the ordinary manner. Cheap cupsmade in the usual style, wired tops, for old mills and repair jobs, con-stantly on hand. Our Improved Fastening. This is of unique benefit, has been utilized given that 1869, and allwho use and see it pronounce it vastly superior. It is a copper claspnicely contrived to firmly clamp the bucket to the belt. It perforatesthe belt and cup via two or three slotted openings. The cup 96 DESCRIPTIVE PAMPHLET OF THE can be effortlessly removed from the belt it does not cut the belt so as toweaken it it prevents the cups from tipping as they pass down. Theexpense is some much more than screws, but these possessing put up commonwarehouse elevators with this fastening, consider it the.cheapest articlein use. Bag Trucks.

Text Appearing Right after Image:

The frequent calls for this helpful write-up has induced us to preparefor and make them in massive quantities, until we uncover ourselves supply-ing the top retail and jobbing homes of the west less costly thanthey have been heretofore supplied by eastern makers. It is a betterconstructed and much more desirable tool than will generally be identified. Wemake a box truck also, similar in style. Conveyor Flights Of all sizes necessary, produced of sugar or maple lumber. They aresmooth, uniform and of desirable shape. In ordering, give dimen-sions of face or front of flight and size of hole you intend driving thetenon into also, the size and sort of wood the shaft is created of RICHMOND MILL FURNISHING Operates. 97 BUCKWHEAT BOLTS. We make these of different sizes. Some are wanted to makeflour swiftly for some certain markets, and require to be of largesize, with medium fine cloth. Those in most typical demand arefor custom mills and of two sizes : 1 with 8 feet, and 1 with 10feet reels in complete chests wi

Note About Pictures

Please note that these pictures are extracted from scanned web page pictures that may possibly have been digitally enhanced for readability – coloration and appearance of these illustrations may possibly not perfectly resemble the original perform.

Image from page 20 of “Descriptive pamphlet of the Richmond Mill Furnishing Performs: all sizes of mill stones and total grinding and bolting combined husk or portable flouring mills, transportable corn and feed mills smut and separating machines zigzag and

Image by Internet Archive Book Pictures

Identifier: descriptivepamph00rich

Title: Descriptive pamphlet of the Richmond Mill Furnishing Operates: all sizes of mill stones and full grinding and bolting combined husk or transportable flouring mills, portable corn and feed mills smut and separating machines zigzag and oat separators, dustless separators, warehouse separators, water wheels mill shafting pulleys spur and bevel, iron and core, gearing ..

Year: 1873 (1870s)

Authors: Richmond Mill Furnishing Functions. [from old catalog]

Subjects: Nordyke, Marmon & Business Flour industry Milling machinery Mills and mill-operate

Publisher: Richmond, Ind., Telegram Steam Print. Co.

View Book Web page: Book Viewer

About This Book: Catalog Entry

View All Photos: All Images From Book

Click here to view book on the internet to see this illustration in context in a browseable online version of this book.

Text Appearing Prior to Image:

ding balance. Standing balance is merely an equal weight on all sides. Running balance is obtaining the center of gravity just as far from theface on a single side as the other. Irregular motion, and no matter how quick, will not have an effect on the runnerwhen balanced as we have explained. If this critical item is correctly attended to, as properly as keepingthe stones in excellent flouring face, there will be significantly less killing of the life offlour, and enabling middlings and unclean bran to escape. The worth 12 DESCRIPTIVE PAMPHLET OF THE of the flour, both as regaids nourishment and wellness, depends on theamount of nutritious, aromatic and saccharine properties retained inthe flour which the wheat consists of. This result depends upon the flouring approach the meal has beensubjected to among the stones. On the amount of these propertiesin the flour also depend the weight and sweetness of the loaf whenbaked likewise its light and white qualities when employed for any pur-pose. ^SBOBUCaiUi RICHMOND MILL FURNISHING Functions.

Text Appearing Right after Image:

BOLTING CLOTHS. — There is a great dealsaid and published bythose who furnishcloths, regarding themerits of the brand ofcloth they sell, and de-merits of other individuals, sothat millers are at aloss exactly where to get,when there is so muchdifference of opinion.When bolting cloth iswanted, all we can askis to address us forsamples to examine. Ifthe cloth is ordered atonce, and you want privilege of examining at express workplace beforepaying for very same, please state it in the order. In the examination ofBolting Cloths parties are frequently led astray some brands of the Frenchand Swiss seem even, smooth and heavy they are nicely sized with akind of gum and sugar of lead, but when utilised awhile their undesirable quali-ties are betrayed by the uneven and fuzzy look. The cloth kept in stock and for sale by us is the brand of Dufour& Co.s Old Dutch Anchor, acknowledged by the most experiencedmill-wrights and millers to be the ideal. We have it imported directby the only importer of this sort of cloth in the Un

Note About Pictures

Please note that these photos are extracted from scanned web page photos that could have been digitally enhanced for readability – coloration and appearance of these illustrations may not perfectly resemble the original operate.

Image from page 88 of “Descriptive pamphlet of the Richmond Mill Furnishing Functions: all sizes of mill stones and comprehensive grinding and bolting combined husk or transportable flouring mills, portable corn and feed mills smut and separating machines zigzag and

Image by Internet Archive Book Photos

Identifier: descriptivepamph00rich

Title: Descriptive pamphlet of the Richmond Mill Furnishing Operates: all sizes of mill stones and full grinding and bolting combined husk or portable flouring mills, transportable corn and feed mills smut and separating machines zigzag and oat separators, dustless separators, warehouse separators, water wheels mill shafting pulleys spur and bevel, iron and core, gearing ..

Year: 1873 (1870s)

Authors: Richmond Mill Furnishing Functions. [from old catalog]

Subjects: Nordyke, Marmon & Organization Flour industry Milling machinery Mills and mill-operate

Publisher: Richmond, Ind., Telegram Steam Print. Co.

View Book Web page: Book Viewer

About This Book: Catalog Entry

View All Pictures: All Images From Book

Click here to view book on the internet to see this illustration in context in a browseable on the internet version of this book.

Text Appearing Just before Image:

dded on eachside of the stream. Observe in cutting the opening or notch to bevelthe edges down stream to inside say ^ of an inch of the side upstream that the edges of the notch sides and bottom be almost sharpbut correct and square, and the complete opening sufficient for the water topass the bottom of the notch can be leveled by letting the waterpass over in a thin sheet then drive a stake three to four feet abovethe dam to a single side or the middle of the stream, and the upper endof it on a level with the bottom of the notch in weir. And now thatyou have the dam produced and in position so that all the water will passthrough the notch and no leaks, let the water to attain its full depth,then take square or rule and measure the exact distance from the best ofthe stake driven in the stream to the prime of the water flowing towardsthe weir 2d. Width of notch 3d. Head and fall, and send to us,and we will give you the power of your stream, size of wheel to dothe preferred labor, &c. *l»^oc§*

Text Appearing Soon after Image:

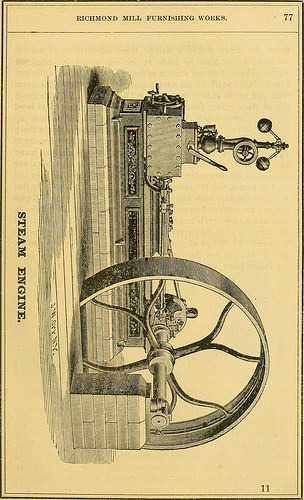

78 DESCRIPTIVE PAMPHLET OF THE ST£AM ENGINES. Careful experiments and practice with a view to appropriately proportionthe motive energy to the work to be carried out has prepared us for givingvaluable information regarding steam engines for the objective offlouring mills. And when requested will furnish the engines them-selves combining the required qualities, and see in particular person that all theparts, speed, &c., &c., be exactly adapted to do the operate. Whenwe furnish the engine, with the other supplies of the mill, which isfrequently the case, our buyers might rest assured all will be satis-factory as regards style of finish, durability, sufficiency of joower, andeconomy in the use of fuel. We do not make engines ourselves, butpurchase them of the very best makers, and if we should be consulted Jnall cases of whom to get, style, kind, &c., or be ordered to supplythe engine direct, our clients will be a lot more most likely to get what is very best. HANGING AND DRIVING MILL IRONS.

Note About Images

Please note that these images are extracted from scanned web page images that might have been digitally enhanced for readability – coloration and appearance of these illustrations could not perfectly resemble the original work.