Check out these milling and machining images:

Image from web page 106 of “Descriptive pamphlet of the Richmond Mill Furnishing Operates: all sizes of mill stones and complete grinding and bolting combined husk or portable flouring mills, transportable corn and feed mills smut and separating machines zigzag and

Image by Web Archive Book Photos

Identifier: descriptivepamph00rich

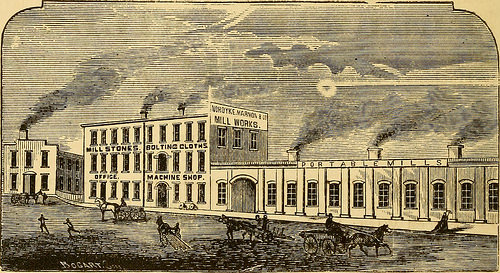

Title: Descriptive pamphlet of the Richmond Mill Furnishing Functions: all sizes of mill stones and full grinding and bolting combined husk or portable flouring mills, portable corn and feed mills smut and separating machines zigzag and oat separators, dustless separators, warehouse separators, water wheels mill shafting pulleys spur and bevel, iron and core, gearing ..

Year: 1873 (1870s)

Authors: Richmond Mill Furnishing Operates. [from old catalog]

Subjects: Nordyke, Marmon & Business Flour business Milling machinery Mills and mill-work

Publisher: Richmond, Ind., Telegram Steam Print. Co.

View Book Page: Book Viewer

About This Book: Catalog Entry

View All Photos: All Pictures From Book

Click right here to view book online to see this illustration in context in a browseable on-line version of this book.

Text Appearing Prior to Image:

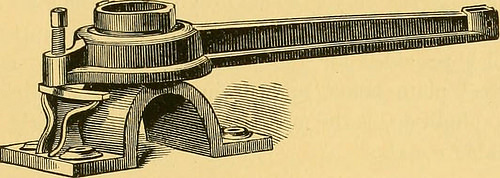

SOCART&SriLLMAN This engraving represents the head and element of the trunk of anElevator, or what is termed an elevator head Fig. 2 (on subsequent web page)represents the elevator foot. An elevator head and foot as furnishedby us contains Fig. 1 and Fig. 2 with turned iron pulleys in them, thenecessary shafting, and an outside bevel or spur gear wheel or turnedpulley to acquire energy for driving the Elevator. RICHMOND MILL FURNISHING Functions. 95 Note.—The iron spicier as represented leaning against the Elevatorhead (Fig. 1) has no connection with any element of it except to showthe shape of our patterns in that line.

Text Appearing Right after Image:

Fig. two.Elevator Cups (Enhanced.) Of all the sizes essential for any type of an elevator we make inour establishment. Having lengthy employed a workman on this workwith special machinery of our personal, and as we buy the stock in largequantities, we are as nicely equipped as it is possible to be for makingthis helpful appendage of a flour mill. Their positive aspects are : dura-bility and economy, the distinct sizes are completely uniform, of thesmaller and medium sizes the physique is produced of heavy tin, and allhaving an iron band neatly and skilfully secured about the upperedge. It makes a completely robust, smooth, at the identical time a lightcup, and providing the least resistance in passing via the grain ofany cup now offered. They are less liable to catch on the sides of the Elevator trunking,and no breaking and tearing as is common to the low-cost wired or roughiron cups sacured to the belt in the ordinary manner. Inexpensive cupsmade in the usual style, wired tops, for old mills and repair jobs, con-stantly

Note About Pictures

Please note that these pictures are extracted from scanned web page images that could have been digitally enhanced for readability – coloration and look of these illustrations could not completely resemble the original operate.

Image from web page 98 of “Descriptive pamphlet of the Richmond Mill Furnishing Works: all sizes of mill stones and full grinding and bolting combined husk or transportable flouring mills, transportable corn and feed mills smut and separating machines zigzag and

Image by World wide web Archive Book Pictures

Identifier: descriptivepamph00rich

Title: Descriptive pamphlet of the Richmond Mill Furnishing Works: all sizes of mill stones and complete grinding and bolting combined husk or transportable flouring mills, transportable corn and feed mills smut and separating machines zigzag and oat separators, dustless separators, warehouse separators, water wheels mill shafting pulleys spur and bevel, iron and core, gearing ..

Year: 1873 (1870s)

Authors: Richmond Mill Furnishing Functions. [from old catalog]

Subjects: Nordyke, Marmon & Firm Flour market Milling machinery Mills and mill-operate

Publisher: Richmond, Ind., Telegram Steam Print. Co.

View Book Web page: Book Viewer

About This Book: Catalog Entry

View All Pictures: All Images From Book

Click here to view book on the web to see this illustration in context in a browseable on-line version of this book.

Text Appearing Before Image:

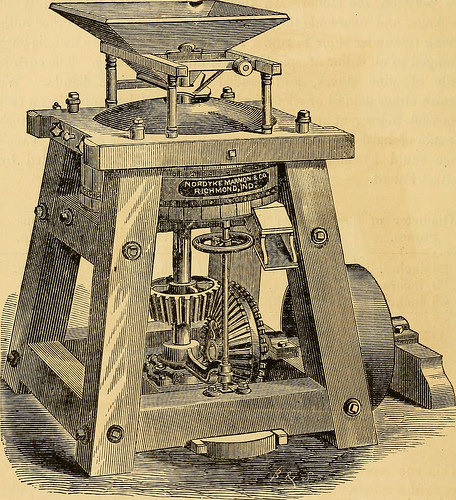

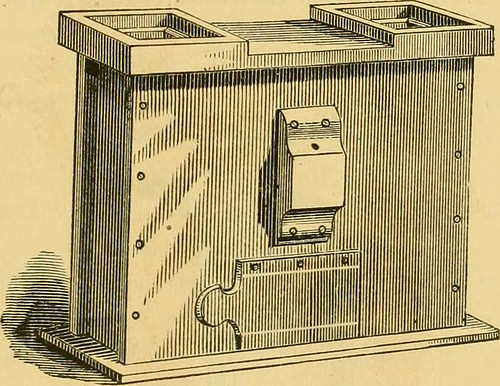

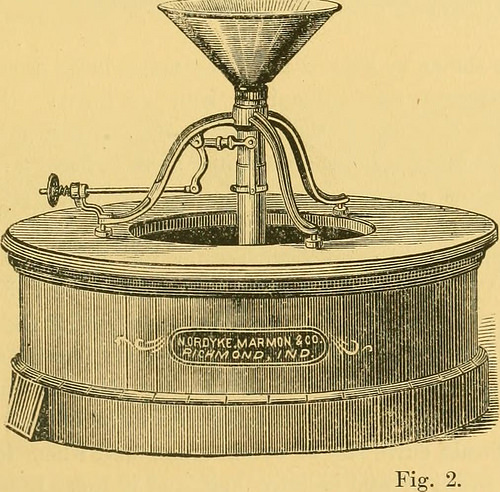

made of double-thickness lapped andtongued and screwed with each other. The body is created of pine staves,worked on a double-headed tongueing and grooving machine created forthis goal, with their mandrels in radius positions to make a closefitting joint for any size we choose to make the outdoors bands are ofblack walnut, below which we place neat iron bands, a single at the baseand a single near the best, beneath the projecting curb or best. For shield-ing the wood from becoming affected, we coat the inside with white lead RICHMOND MILL FURNISHING Performs. paint, and give the outside three coats of good varnish. In thepieparation to ship them and keep each portion from the liability ofdamaging in the least, we make a complete protection of a light framework and circle pieces surrounding the complete. When the hopperframe and feed rig is ordered we spot them inside. This not onlymakes a powerful and sturdy cover to the mill-stone, but one particular that forstyle of finish and attractive appearance pleases all. Silent Feeders.

Text Appearing Following Image:

Of these we make some half a dozen kinds, differing somewhat in con-struction and look, some of which are shown in the accompany-ing cuts. Fig. 1 is of the style identified as the glass globe tripod.The globe is made of the greatest clear flint glass from 1-fourth to one particular-half inch in thickness. The iron frame can be hfted from itsbearings on the curb at any time. The hand wheel and screw bywhich the feed to the stone is regulated, is provided with a spring sothat by pressing upon the wheel the feed tube can be suddenly raisedif necessary, when by the action of the spring it will take its exactposition as prior to. All the parts are carefully fitted up, the hand wheeland such other components turned as essential to full it in a tastefulmanner. DESCRIPTIAE PAIVIPHLET OF THE

Note About Images

Please note that these pictures are extracted from scanned page photos that could have been digitally enhanced for readability – coloration and look of these illustrations could not completely resemble the original operate.