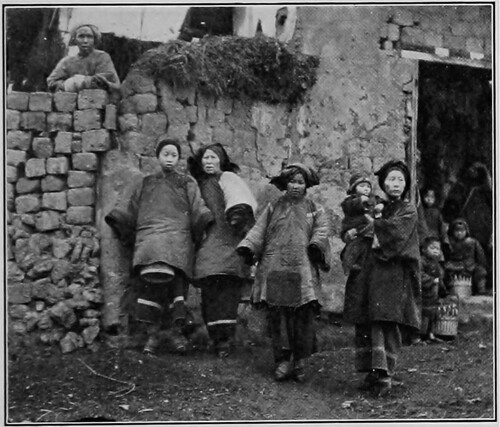

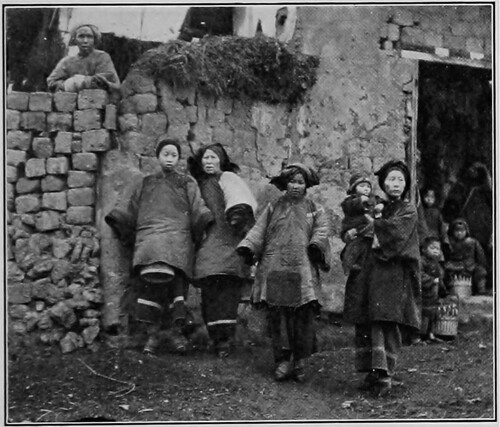

Some cool sheet metal china pictures:

Image from web page 100 of “An American engineer in China” (1900)

Image by World wide web Archive Book Photos

Identifier: cu31924023226081

Title: An American engineer in China

Year: 1900 (1900s)

Authors: Parsons, William Barclay, 1859-1932

Subjects: Parsons, William Barclay, 1859-1932 Railroads

Publisher: New York, McClure, Phillips & co.

Contributing Library: Cornell University Library

Digitizing Sponsor: MSN

View Book Page: Book Viewer

About This Book: Catalog Entry

View All Pictures: All Photos From Book

Click here to view book on the web to see this illustration in context in a browseable online version of this book.

Text Appearing Ahead of Image:

set, I donot know, but the last we saw of that man he washugging his rind like a ti-easure. Before we hadseen the last of his horse, nonetheless, we felt that ifthe pumaloe rind had constituted the complete ofthe acquire-cost we still need to have been thelosers. It is surprising how closely the men and women in onesection of the country pattern after those else-where, when one particular remembers the lack, almostabsolute lack, of intercommunication. But inspite of the basic sameness, which perhapsappears higher than it is on account of the uni-formity in physiognomy of the men and women, with theMongolian coloring and jet-black hair, there weremany pecuHar customs which appeared to belocalized, as numerous of them were found only in Chapter III: Hu-nan, the Closed Province 95 tiny districts, and travelled Chinese who accom-panied me, stated that they had in no way prior to seensimilar things elsewhere in the empire. Of thesethe most singular was the carrying of tiny bam-boo baskets lined with sheet metal and filled with

Text Appearing Soon after Image:

A Peculiar Custom by Chinese Women of Wearing Heat-ing-Baskets hot wood-ashes. Such baskets the girls in onelocality suspend from a belt beneath their shortblouses. Occasionally the baskets are worn infront, often behind, and occasionally in bothplaces, according, apparently, to the fancy of thewearer. Youngsters also produced use of the heating 96 An American Engineer in China apparatus, but men only seldom. No matter howworn, the effect in all situations was both extraordi-nary and comical. To get a photograph of Chi-nese ladies is almost as hard as to photographa herd of wild deer. Girls are supposed tokeep away from any man, and of course a foreignman is specially terrible. The picture of thewomen and their baskets was obtained by cau-tious stalking behind some Chinese, even though theirattention was attracted by 1 of the members ofmy employees. The immediate after the shutter droppedthe group had scattered. In farming strategies the Chinaman in the inte-rior is, of course, centuries behind. His gra

Note About Images

Please note that these images are extracted from scanned page photos that may possibly have been digitally enhanced for readability – coloration and look of these illustrations may not completely resemble the original work.

Image from web page 142 of “The art of lead burning a practical treatise explaining the apparatus and processes” (1905)

Image by Internet Archive Book Images

Identifier: artofleadburning00fayc

Title: The art of lead burning a practical treatise explaining the apparatus and processes

Year: 1905 (1900s)

Authors: Fay, C. H

Subjects: Lead burning

Publisher: New York, D. Williams company

Contributing Library: The Library of Congress

Digitizing Sponsor: The Library of Congress

View Book Page: Book Viewer

About This Book: Catalog Entry

View All Pictures: All Photos From Book

Click right here to view book on the internet to see this illustration in context in a browseable on-line version of this book.

Text Appearing Ahead of Image:

d just as forlead. Britannia metal is fast becoming the favoritelining for splash and drip boards on butlers pan-attempt sinks, as also for lining the function benches insaloons. It is soft enough to enable the most deli-cate china to be laid on it with no danger of chip-ping, and is also quite straightforward to preserve clean. It takesa high polish and constantly looks well. The methodof cutting the metal for a butlers pantry sink isshown in Fig. 51, the dotted lines showing theactual dimensions of the write-up to be covered,although the complete lines show the laps required tocover the edges of the board. This metal isharder than lead, and will not dress smooth withthe dresser. Any uneven spots have to be presseddown with a hot flatiron. The approach of turn-ing the edges is shown at a. The bending iron isheated and rubbed over the edge, progressively turn- THE ART OF LEAD BURNING. 139 ing the edges till they are at their suitable posi-tion. The iron must be constantly heated to in-positive the ideal final results, and if appropriately carried out no

Text Appearing Soon after Image:

cq CQ 1 140 THE ART OF LEAD BURNING. wrinkles will seem. A lined perform bench isalso shown in Fig, 52, which shows the methodof placing in the bar washer. The sheet metalmust be cut and fitted to its place and all theseams feasible ought to be soldered before placingthe metal in position. The edges must be tackedon the beneath side of the function, when practicable,with copper tacks. Sooner or later the blow pipe solderer will becalled upon to make repairs on Britannia metal,and will be shocked to discover that it will be impos-sible to solder the metal, owing to the excess ofmoisture beneath it. The greatest way to overcomethis, which is practically the only difficulty thatoccurs, is to reduce out a little square patch. Theedge can be cleaned and a patch of new metalcarefully fitted into the hole. When prepared to be-gin soldering, a piece of blotting paper ought to beinserted amongst the patch and board. Thispaper will absorb all the moisture and let theseam to be neatly soldered. The man who makeshimself

Note About Images

Please note that these images are extracted from scanned web page pictures that might have been digitally enhanced for readability – coloration and appearance of these illustrations could not perfectly resemble the original work.

Image from web page 620 of “Mechanical Contracting & Plumbing January-December 1912” (1912)

Image by Net Archive Book Images

Identifier: mechcontract1912toro

Title: Mechanical Contracting & Plumbing January-December 1912

Year: 1912 (1910s)

Authors:

Subjects: Air conditioning Refrigeration and refrigerating machinery Heating Plumbing

Publisher: Toronto : Maclean-Hunter Pub. Co.

Contributing Library: Fisher – University of Toronto

Digitizing Sponsor: University of Toronto

View Book Page: Book Viewer

About This Book: Catalog Entry

View All Photos: All Pictures From Book

Click right here to view book on-line to see this illustration in context in a browseable on-line version of this book.

Text Appearing Just before Image:

-■•mum We Can FurnishYour Requirements in All PLUMBING GOODS We handle a total line of Enameled Baths Enameled LavatoriesSinks and Laundry Tubs

Text Appearing Soon after Image:

Write us about ourVictorian China Lavatories. The James Morrison Brass Mfg.Company, Ltd. Producers and dealers in a completeline of Plumbing and Heating Supplies 93-97 Adelaide Street West TORONTO 19 Complete Course in Sheet Metal Work In prob. 23, plate 21, fig. 1 representsa pail, of which A-B is a boss, or rein-forcement on the deal with. The pattern is just a circle havingthe identical curve as the deal with, and iscut out to shape shown by fig. two, thenformed to shape by fig. three, and solderedto deal with. In prob. 24, fig. 1, is a strainer pail,the brest B is developed the exact same as thebrest on the watering pail, prob. 18,plate 20. To develop the spout A, continue theline C- any distance, and parallel to By L. W. KOSER this carry a line from the point V, asV-7. Draw a cross section of the spout fig.2, then divide it into equal spaces andcarry lines from exact same till they cut thelines O-V and C-V. Lay out a stretchout at correct anglesto C-O, as fig. three, and carry lines fromthe distinct points o

Note About Photos

Please note that these photos are extracted from scanned web page photos that could have been digitally enhanced for readability – coloration and look of these illustrations may not perfectly resemble the original operate.