Speedy Components Manufacturing Inc. RAPIDPARTS.CA You Draw it. We Make it. Business. CUSTOM metal precision part generating machine shop service for your machining ne…

Video Rating: 3 / 5

Rapid Prototyping China

Speedy Components Manufacturing Inc. RAPIDPARTS.CA You Draw it. We Make it. Business. CUSTOM metal precision part generating machine shop service for your machining ne…

Video Rating: 3 / 5

Playing with PowerDirector on some video I took of the CNC machine cutting out some prototype jukebox kits.

Video Rating: 5 / five

Element Six to develop ultrafast-pulse disk lasers for precision machining

The new laser will be designed with higher average output power to improve productivity and precision in micromachining of transparent components. As element of the three-year project titled "Ultrafast High-Average Power Ti:Sapphire Thin-Disk Oscillators …

Study much more on Industrial Laser Solutions Magazine

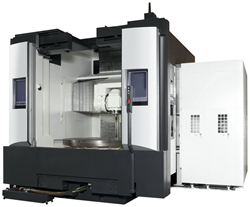

Machining Center Balances Precision, Productivity

Kern Precision's Ultra Precision EVO CNC machining center is equipped for three- to 5-axis machining of medium to big lot sizes. The machine provides high productivity via fast acceleration, feed prices and spindle speeds as higher as 50,000 rpm …

Study much more on Contemporary Machine Shop

Transfer Machining Center Produces Tiny Precision Parts

²) with minimum chip-to-chip instances of .five sec., thanks to linear motors in all axes. The transfer center consists of 4 workstations, every single equipped with two higher-speed, 60,000-rpm spindles, that perform simultaneously to give high-precision and quick …

Study much more on Contemporary Machine Shop

We recognize that you literally have thousands of choices when it comes to selecting a supplier to supply you with precision machining services. Nevertheless, we…

Video Rating: / five

Huge parts CNC Machining by Trace-A-Matic. TAM is a leading CNC Machining Job Shop in Milwaukee, Wisconsin. Properly-known for very-engineered CNC machined pa…

Video Rating: 5 / 5

www.cadcam123.com. Powerful and effortless in use 2D two,5D cadcam software for NC milling and lathe jobs. Free of charge downloads trial version. Import and export of DXF and…

Video Rating: 5 / five

Omnitech Selexx CNC Router machining various strong wood components such as door, window, and furniture parts. For more info on our variety of woodwork…

Video Rating: / five

Clearwater, FL (PRWEB) April 30, 2014

BobCAD-CAM, Inc. develops CAD/CAM CNC machining software program for manufacturing businesses. They have just released the new v26 Wire EDM 2 & four Axis CAD/CAM software program, adding it to their line of CNC programming computer software merchandise. Their CAD/CAM goods improve workflow efficiency by streamlining the process of choosing tools, materials and cutting methods which can be quite time consuming and produces the numeric code that the machine requires to really machine the portion rapidly and error cost-free. With the new release of their Wire EDM module, CNC machining companies that use Wire Electrical Discharge Machines can completely streamline and automate the approach of creating dies and other precision components that call for EDM programming.

“The Tool & Die industry and any precision Wire EDM shop will truly benefit from becoming in a position to program their two or 4 axis EDM parts with this technologies as we have added machining wizards and dynamic machining methods for 2 and four axis programming along with a extended list of inside, outside and open shape cutting operations that actually streamline EDM portion producing,” mentioned Greg Myers, who oversees Software Improvement at BobCAD-CAM.

The new v26 Wire EDM CAD/CAM release has received a main overhaul and now contains many of the effective enhancements that were added to the milling software program but only customized for what an EDM programmer wants. New characteristics start off with new machining wizards for producing outdoors and inside cutting toolpaths as well as open shape cutting for two Axis and four axis programming. All wire toolpath machining operations use these machining Wizards. These machining wizards step the operator by way of all of the required stages necessary to produce a two or four axis system fundamentally removing the guesswork from programming. The new Dynamic Machining Methods functionality also allows the operator to add Rough Reduce, Skim Cuts, and Tab Cut operations on the fly. For the very first time ever, BobCAD-CAM now gives strong simulation for Wire EDM with this new release.

The new CAM Tree manager makes it possible for the operator to keep cutting operations, machine configurations, cutting circumstances, post processing and every thing else involved all in 1 location and easy to handle. Posting has been tremendously enhanced. For instance, many predefined processing orders are now available and operators can just modify the posting order with the press of a button, or totally customize their posting order to meet their requirements. Copy and Pasting characteristics and machine operations is also an added benefit.

“The new v26 Wire EDM CAD/CAM system has a lot to supply the Wire EDM machining market for precision part creating,” added Myers.

For much more info on this new 2 & 4 Axis Wire EDM CAD/CAM software program, make contact with BobCAD-CAM straight at 877-262-2231 or 727-442-3554.

Charlotte, NC (PRWEB) August 21, 2014

At IMTS 2014, Okuma will introduce its new VTM-2000YB multitasking CNC turning center, which provides heavy-duty construction for huge parts machining. The extreme rigidity and strong cutting capabilities of this machine make it excellent for machining huge diameter workpieces, such as those in the aerospace sector. The vertical architecture provides the benefit of “natural” element handling and outstanding chip fall, although taking up minimal floor space. At IMTS this machine will be using the full work envelope, cutting on a fan hub and engine case, featuring Super-NURBS and tooling from Sandvik, a member of Partners in THINC.

The VTM-2000YB requires the profitable notion of the VTM-200YB and advances the style to enhance rigidity, energy, B-axis range, speed and accuracy. It utilizes Okuma’s Thermo-Friendly Idea to enhance thermal stability, and has potent turning and milling capabilities with .001° B and C axes. This CNC turning center has 1.6 meters of Y-axis travel, combines powerful turning and milling functions for massive parts in the exact same machine and includes a 36 tool ATC for tool changing.

Important Specs of VTM-2000YB CNC Turning Center

Max Turning Diameter mm (in) Ø 2,000 (Ø 78.74″)

Spindle Nose Sort 380mm Flat Nose

Lathe Spindle Speed min⁻¹ 4~200

Milling Spindle Speed min⁻¹ 10,000

Fast Traverse (X/Y/Z) m/min (ipm) 32/32/32 (1,260/1,260/1,260)

Fast Traverse (B/C) rpm 19.5/20

For a lot more information on Okuma’s VTM-2000YB pay a visit to the Okuma Booth S-8500 at IMTS 2014.

About Okuma America Corporation

Okuma America Corporation is the U.S.-primarily based sales and service affiliate of Okuma Corporation, a planet leader in CNC (laptop numeric control) machine tools, founded in 1898 in Nagoya, Japan. The organization is the industry’s only single-supply provider, with the CNC machine, drive, motors, encoders, spindle and CNC manage all manufactured by Okuma. Okuma’s revolutionary and trustworthy technologies, paired with complete, localized service protection, permits customers to run constantly with self-assurance – maximizing profitability. Along with its sector-leading distribution network (largest in the Americas), and Partners in THINC, Okuma facilitates high quality, productivity and efficiency, empowering the customer and enabling competitive advantage in today’s demanding manufacturing environment. For much more data, check out http://www.okuma.com or adhere to us on Facebook or Twitter @OkumaAmerica.

About Partners in THINC

Partners in THINC is a collaboration network of a lot more than 40 business leaders who come together to resolve troubles and explore new productivity ideas for real-world producers. With the open architecture, Pc-primarily based THINC®-OSP handle as its nucleus, Partners in THINC brings specialized equipment, expertise and a commitment to give the ideal attainable integrated options to the finish-user. For far more details, visit http://www.okuma.com/partners-in-thinc.

###

Hardinge Inc. to Present at the 2014 Western New York Investors Conference

16, 2014 (GLOBE NEWSWIRE) — Hardinge Inc. (Nasdaq:HDNG), a leading international provider of sophisticated metal-cutting solutions and accessories, announced these days that Richard L. Simons, Chairman, President and Chief Executive Officer, and Douglas J …

Read much more on Stockhouse

Snecma (Safran) and RTI International Metals Sign Titanium Aluminide Provide …

RTI delivers titanium mill goods, extruded shapes, formed and 3D-printed parts, and extremely engineered precision-machined elements by way of our downstream integrated supply chain. Headquartered in Pittsburgh, Pa., RTI has areas in the United …

Study much more on MarketWatch

Just In Time Machining Invests At Least .2 Million In Ocala, Florida …

Given that its founding in 1996, JIT has applied its focus on becoming a complete-service, family members-owned, CNC or automated machinery shop offering prototyping, CNC and CNC-turn mill machining, drilling, milling, turning and sawing, welding and metal fabrication …

Study far more on Region Improvement On the web

Just In Time Machining will locate its new production facility in Ocala …

“We are proud to officially welcome a new manufacturing company, Just in Time Machining, to Marion County. Their CNC machine shop will bring 25 new complete-time jobs to our regional workforce with an average salary of $ 37,000 for CNC operators. Our Board's …

Study a lot more on Region Improvement On-line