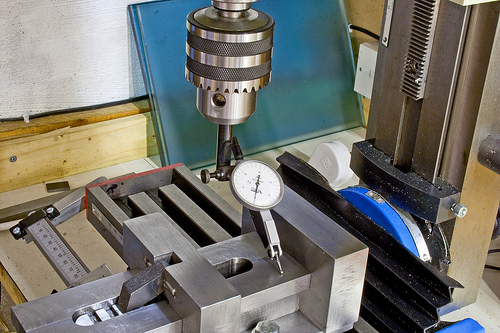

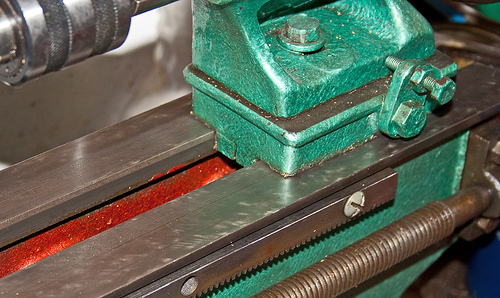

Some cool speedy precision machining pictures:

Steven F. Udvar-Hazy Center: South hangar panorama, such as Vought OS2U-3 Kingfisher seaplane, B-29 Enola Gay, among other people

Image by Chris Devers

Quoting Smithsonian National Air and Space Museum | Vought OS2U-three Kingfisher:

The Kingfisher was the U.S. Navy’s principal ship-based, scout and observation aircraft for the duration of Globe War II. Revolutionary spot welding techniques gave it a smooth, non-buckling fuselage structure. Deflector plate flaps that hung from the wing’s trailing edge and spoiler-augmented ailerons functioned like further flaps to let slower landing speeds. Most OS2Us operated in the Pacific, where they rescued numerous downed airmen, like World War I ace Eddie Rickenbacker and the crew of his B-17 Flying Fortress.

In March 1942, this airplane was assigned to the battleship USS Indiana. It later underwent a six-month overhaul in California, returned to Pearl Harbor, and rejoined the Indiana in March 1944. Lt. j.g. Rollin M. Batten Jr. was awarded the Navy Cross for creating a daring rescue in this airplane below heavy enemy fire on July four, 1944.

Transferred from the United States Navy.

Manufacturer:

Vought-Sikorsky Aircraft Division

Date:

1937

Country of Origin:

United States of America

Dimensions:

All round: 15ft 1 1/8in. x 33ft 9 1/2in., 4122.6lb., 36ft 1 1/16in. (460 x 1030cm, 1870kg, 1100cm)

Components:

Wings covered with fabric aft of the major spar

Physical Description:

Two-seat monoplane, deflector plate flaps hung from the trailing edge of the wing, ailerons drooped at low airspeeds to function like further flaps, spoilers.

• • • • •

Quoting Smithsonian National Air and Space Museum | Boeing B-29 Superfortress "Enola Gay":

Boeing’s B-29 Superfortress was the most sophisticated propeller-driven bomber of Globe War II and the initial bomber to property its crew in pressurized compartments. Though designed to fight in the European theater, the B-29 discovered its niche on the other side of the globe. In the Pacific, B-29s delivered a variety of aerial weapons: standard bombs, incendiary bombs, mines, and two nuclear weapons.

On August six, 1945, this Martin-constructed B-29-45-MO dropped the first atomic weapon utilised in combat on Hiroshima, Japan. Three days later, Bockscar (on show at the U.S. Air Force Museum close to Dayton, Ohio) dropped a second atomic bomb on Nagasaki, Japan. Enola Gay flew as the advance weather reconnaissance aircraft that day. A third B-29, The Fantastic Artiste, flew as an observation aircraft on each missions.

Transferred from the United States Air Force.

Manufacturer:

Boeing Aircraft Co.

Martin Co., Omaha, Nebr.

Date:

1945

Nation of Origin:

United States of America

Dimensions:

All round: 900 x 3020cm, 32580kg, 4300cm (29ft six five/16in. x 99ft 1in., 71825.9lb., 141ft 15/16in.)

Materials:

Polished all round aluminum finish

Physical Description:

4-engine heavy bomber with semi-monoqoque fuselage and higher-aspect ratio wings. Polished aluminum finish overall, normal late-Planet War II Army Air Forces insignia on wings and aft fuselage and serial number on vertical fin 509th Composite Group markings painted in black "Enola Gay" in black, block letters on lower left nose.

Steven F. Udvar-Hazy Center: B-29 Superfortress “Enola Gay” panorama

Image by Chris Devers

Quoting Smithsonian National Air and Space Museum | Lockheed P-38J-10-LO Lightning :

In the P-38 Lockheed engineer Clarence "Kelly" Johnson and his group of designers created one particular of the most productive twin-engine fighters ever flown by any nation. From 1942 to 1945, U. S. Army Air Forces pilots flew P-38s more than Europe, the Mediterranean, and the Pacific, and from the frozen Aleutian Islands to the sun-baked deserts of North Africa. Lightning pilots in the Pacific theater downed more Japanese aircraft than pilots flying any other Allied warplane.

Maj. Richard I. Bong, America’s top fighter ace, flew this P-38J-ten-LO on April 16, 1945, at Wright Field, Ohio, to evaluate an experimental technique of interconnecting the movement of the throttle and propeller handle levers. However, his appropriate engine exploded in flight prior to he could conduct the experiment.

Transferred from the United States Air Force.

Manufacturer:

Lockheed Aircraft Organization

Date:

1943

Nation of Origin:

United States of America

Dimensions:

All round: 390 x 1170cm, 6345kg, 1580cm (12ft 9 9/16in. x 38ft four five/8in., 13988.2lb., 51ft 10 1/16in.)

Supplies:

All-metal

Physical Description:

Twin-tail boom and twin-engine fighter tricycle landing gear.

• • • • •

Quoting Smithsonian National Air and Space Museum | Boeing B-29 Superfortress "Enola Gay":

Boeing’s B-29 Superfortress was the most sophisticated propeller-driven bomber of World War II and the first bomber to residence its crew in pressurized compartments. Though created to fight in the European theater, the B-29 discovered its niche on the other side of the globe. In the Pacific, B-29s delivered a selection of aerial weapons: traditional bombs, incendiary bombs, mines, and two nuclear weapons.

On August 6, 1945, this Martin-constructed B-29-45-MO dropped the very first atomic weapon used in combat on Hiroshima, Japan. Three days later, Bockscar (on show at the U.S. Air Force Museum near Dayton, Ohio) dropped a second atomic bomb on Nagasaki, Japan. Enola Gay flew as the advance weather reconnaissance aircraft that day. A third B-29, The Great Artiste, flew as an observation aircraft on both missions.

Transferred from the United States Air Force.

Manufacturer:

Boeing Aircraft Co.

Martin Co., Omaha, Nebr.

Date:

1945

Nation of Origin:

United States of America

Dimensions:

General: 900 x 3020cm, 32580kg, 4300cm (29ft 6 five/16in. x 99ft 1in., 71825.9lb., 141ft 15/16in.)

Components:

Polished general aluminum finish

Physical Description:

4-engine heavy bomber with semi-monoqoque fuselage and high-aspect ratio wings. Polished aluminum finish overall, regular late-World War II Army Air Forces insignia on wings and aft fuselage and serial quantity on vertical fin 509th Composite Group markings painted in black "Enola Gay" in black, block letters on decrease left nose.