Shenzen, China (PRWEB) January 02, 2015

HLH Prototypes provides some of the best prototyping solutions, which includes high quality CNC machining services in China. The organization is dedicated to high quality and service even though striving to provide clientele with the highest levels of both. They are currently are regarded as the initial option for ideal prototyping service by numerous businesses about the globe. They invest heavily in technologies and folks although keeping rates low.

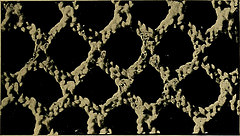

“HLH has the engineering experience that provides practical and inexpensive prototyping services to clients positioned all over the world,” says Xenia Xie. Their very best prototyping service is able to assistance low-to-mid-volume production of plastic and metal components. HLH Prototypes uses technologies like CNC, SLA, SLS and FDM let for low volume production and for higher volumes we offer rapid tooling or injection molding.

HLH Prototypes is a leading provider of CNC machining, additive manufacturing or 3D printing, fast prototyping, injection molding and fast tooling services. They are capable of completing projects with exceptional and varied finishes and high precision and accuracy. Many organizations use HLH Prototypes for their machining, prototyping and contract manufacturing.

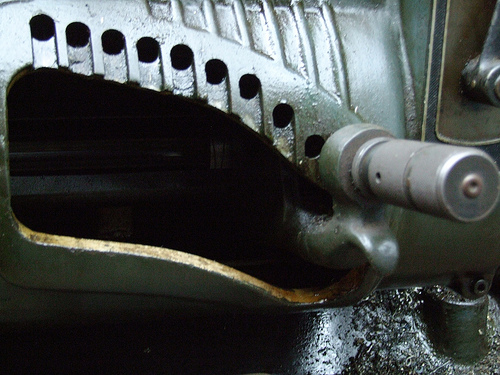

“HLH Prototypes offers high high quality CNC machining services in China,” says a organization representative. Their work is quickly, precise and expense successful. HLH Prototypes is in a position to machine prototypes in a variety of plastics and metals. Their 3, four and 5 axis CNC machines consist of some of the highest top quality found in the sector. They plastics they machine are ABS, Pc, PMMA, Nylon, Nylon +GF, PPS, PEEK, PP, POM, and other individuals. The metals they machine are aluminum, steel, stainless steel, copper, brass, and much more.

The higher top quality CNC machining solutions in China is a result of the greatest prototyping service kind HLH Prototypes. Their investment in equipment and the individuals that run that gear has evolved a low price service at the highest high quality. Their facilities use state-of-the-art equipment that supplies the very best prototyping service using plastics and metals. As the very best speedy tooling prototyping solutions, they have earmarked a spot for themselves.

About The Business:

HLH Prototyping offers the best prototyping service with higher high quality CNC machining services in China. They will be attending a lot of events in 2015 to function the advancement in their solutions. In March 2015 they will attend the TCT Show + Customized which is the top occasion devoted to 3D printing, additive manufacturing and product development. When it comes to speedy prototyping service, they are really ahead of the other folks.