Charlotte, NC (PRWEB) March 25, 2015

Okuma America Corporation, a planet-leader in CNC machine tool manufacturing, hosted higher college students from the Floyd D. Johnson Technologies Center, York Complete High College, York, South Carolina on Friday, March 13 in Charlotte, North Carolina. This exclusive event gave students the chance to find out much more about CNC machining technologies and career possibilities in the machine tool industry.

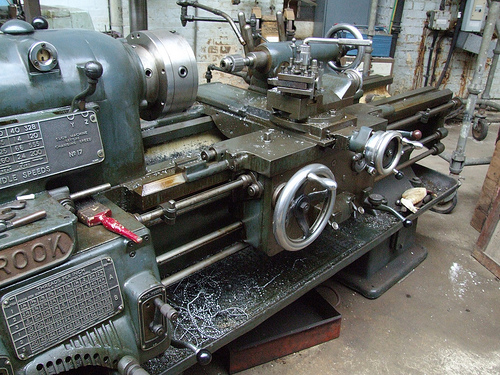

The pre-engineering students toured Okuma Headquarters, the Aerospace Center of Excellence and the Partners in THINC technologies center. Okuma America President & COO Jim King, and Okuma sales and technical specialists educated students about career possibilities as engineers, machine tool operators, programmers and service experts. The students viewed reside cutting demonstrations on state-of-the-art machine tools in addition to trying their hand at the manual art of hand scraping.

“Community outreach is critical to Okuma. We’re pleased to be able to showcase our facilities and technologies and introduce students to the wide selection of career possibilities accessible in the manufacturing market. Hopefully their time spent right here ignites a passion for the machine tool business,” mentioned Jim King, President & COO.

Okuma is hosting many student-focused, educational events during the upcoming year which includes a unique occasion in October to celebrate Manufacturing Day. For much more info on Okuma America Corporation and Partners in THINC pay a visit to http://www.okuma.com/.

About Okuma America Corporation

Okuma America Corporation is the U.S.-based sales and service affiliate of Okuma Corporation, a planet leader in CNC (personal computer numeric manage) machine tools, founded in 1898 in Nagoya, Japan. The organization is the industry’s only single-supply provider, with the CNC machine, drive, motors, encoders, spindle and CNC control all manufactured by Okuma. Okuma’s innovative and reliable technology, paired with complete, localized service protection, permits users to run continuously with self-assurance – maximizing profitability. Along with its industry-top distribution network (biggest in the Americas), and Partners in THINC, Okuma facilitates quality, productivity and efficiency, empowering the customer and enabling competitive advantage in today’s demanding manufacturing environment. For far more information, go to http://www.okuma.com/ or stick to us on Facebook or Twitter @OkumaAmerica.

About Partners in THINC

Partners in THINC is a collaboration network of far more than 40 business leaders who come together to solve problems and explore new productivity ideas for real-globe manufacturers. With the open architecture, Computer-based THINC®-OSP handle as its nucleus, Partners in THINC brings specialized equipment, expertise and a commitment to give the ideal possible integrated options to the finish-user. For far more details, pay a visit to http://www.okuma.com/partners-in-thinc.

###

Associated Cnc Engineering Press Releases