Shenzhen, China (PRWEB) May 15, 2015

HLH Prototypes Co Ltd has emerged as a name synonymous with quality, reliability and cost effectiveness. Acclaimed as one of the largest and longest running prototyping and contract-manufacturing bureaus in China, HLH Prototypes is doing a tremendous job when it comes to offering quality bespoke solutions including prototyping, CNC machining and manufacturing services to its clients scattered all across the globe.

Talking about precision machining parts, Susie Su executive at HLH Prototypes, said, “Our credentials in delivering cost efficient precision machining parts make us stand out. Businesses of varied sizes across all industries rely upon us to provide high precision, high accuracy CNC machining and CNC turning of aluminum, steels and other metals and plastics. And in line with our stringent QC requirements and continuous improvement policy we seldom disappoint them. We have technology and experience to deliver CNC machining parts for both low to mid and high volume production runs.”

Courtesy of its own UKAS ISO9001:2008 accredited modern facilities located in Shenzhen, China, HLH Prototypes can offer high precision prototyping and finishing services backed by prompt lead times, while retaining the cost effectiveness. The prototyping and contract-manufacturing bureau offers prototype or volume machined parts in a selection of materials to cater to client’s requirements. Identifying the requirements of clients, it generates creative ideas to design prototypes. It employs innovative methods such as hand-sketching, 2D & 3D CAD modeling, mechanical drawing and product rendering to accomplish the designing jobs before entering the final prototype production stage.

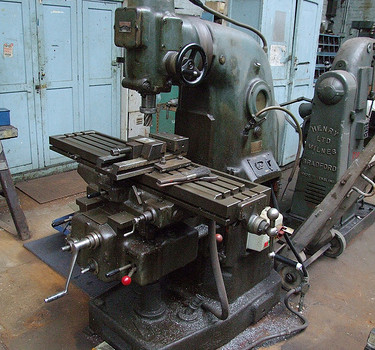

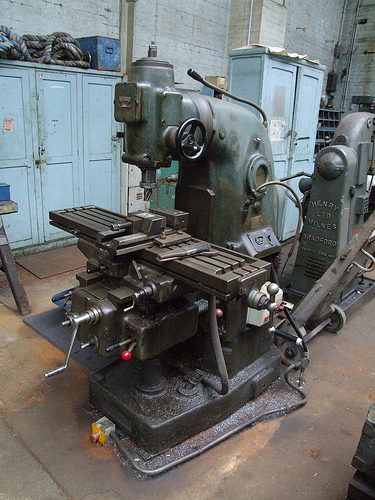

Susie Su further stated, “CNC machining is fast, accurate and cost effective and, hence a perfect choice for many projects. We have the experience, expertise and technology to deliver exceptional rapid prototyping and machining of prototypes and parts in a wide assortment of materials including plastics and metals. Our 3, 4 and 5 axis CNC machines are the best available in the industry and combine a mix of both domestic and imported high precision machines perfect for any job.”

For HLH Prototypes, quality is the paramount concern. Hence, it does everything possible to ensure the quality standards of its services. In pursuit of professional excellence, the prototyping and contract-manufacturing bureau invests heavily in technology. Its well-equipped facilities are run by few of the most proficient and seasoned professionals who are aware of the nuances of the trade. Backed by innovative equipment, they are capable of accomplishing tasks of any magnitude, within the specified time. Therefore, HLH Prototypes is the place to avail superior yet affordably priced CNC machining services China.

About HLH Prototypes:

With the base of operations in Shenzhen, China, HLH Prototypes is one of the largest and longest running prototyping and contract-manufacturing bureaus in China. It has proven credentials in offering a selection of services including precision CNC machining and turning, vacuum casting and reaction injection molding, SLA and SLS 3D printing and hand sculpture plus rapid and production tooling and sheet metal work all under one roof. It is also the ideal destination for those looking for aluminum prototyping in China. All these attributes make HLH Prototypes the preferred destination for availing plastic machining services at reasonable prices.

Contact Information:

HLH Prototypes

Office: 1801 Xing Ji Building, Xin Sha Road, Shajing, Baoan, Shenzhen, China, 518125

Factory: 2nd floor, Building 6, Hua Fa Industrial Park, Fu Yuan 1st Road, Fuyong, Baoan, Shenzhen, China

Tel: +86-755-82569129 (ext 817 for English)

Fax: +86-755-82569136

Email: info(at)hlhprototypes(dot)com

Web: http://www.hlhprototypes.com/

North America

Tel: +1 (305) 508-5958

Latin and South America (Spanish and Portuguese)

Tel: +55 47 30341953 | +55 47 96047686

Email: hlh(dot)lar(at)hlhprototypes(dot)com

Skype: lar-hlh

# # #

Find More Sheet Metal China Press Releases