www.toplevelcnc.com CNC Machined Components, Aluminum Machining Components, Aluminum Machined Components Supplier, Aluminum Machining China, Aluminum CNC Machining, Custom …

Video Rating: 5 / five

Machining

Most recent Advanced Precision Machining News

3D Systems acquires American Precision Prototyping, Machining to expand …

ROCK HILL, S.C. 3D Systems has acquired sister companies American Precision Prototyping (APP) and American Precision Machining (APM), providers of speedy prototyping and advanced manufacturing, engineering services, and solution improvement.

Study a lot more on Military Embedded Systems

What's next for packaging machinery automation?

The application of advanced motion technology for packaging machinery took a different trajectory than that taken for machine tools. Though machine tools make some extremely quick movements, they usually do so on single components …. Beckhoff talked about the …

Read much more on Packaging World

How Linear Encoders Boost Precision Machining Tools And How Cold Forging Operates

Precision machining tools have been greatly enhanced by linear encoders in a number of methods. A linear encoder is a sensor, transducer or readhead paired with a scale that encodes position. It performs by the sensor reading the scale and converting that encoded position into a digital signal which is then decoded into position by a digital readout. Linear encoders are utilised in metrology instruments and precision machining tools such as digital calipers and coordinate measuring machines. Linear encoders use many distinct physical properties to encode the position such as optical, magnetic, inductive, and capacitive.

Optical linear encoders are the most common kind of encoder on the marketplace nowadays especially for precision machining tools. A standard scale for optical linear encoders varies from hundreds of microns down to just a couple of. This type of scale is really accurate and precise which is why it dominates most of the industry. The magnetic encoders are yet another favourite and they function by scales that are either active which is magnetized or passive which is reluctance.

There are two main applications for linear encoders including measurement and motion systems. Measurement is specifically important when it comes to precision machining because it needs to be correct down to the hundredth of a millimeter. Linear encoders for measurement are commonly found in coordinate measuring machines (CMM), laser scanners, calipers, gear measurement, tension testers, and digital study outs. Motion systems from linear encoder also aid precision machining since they supply precise higher speed movement.

Linear encoders are either open or closed which can carry various positive aspects and disadvantages. Being open they are prone to dirt particularly getting in precision machining tools and machines. Nonetheless enclosing the encoder limits it accuracy due to friction. The alternative of the encoder becoming closed or open in a machine demands to be thought about on a case by base basis.

Precision Machining accomplished with Cold Forging?

It has been identified and tested that precision cold forging creates perfectly shaped parts with easy or complex geometry and it’s faster than machining. Precision machining is the most well-known way of generating tools and parts for machinery but it is quite expensive due to the machines and the length of time it requires to generate the components. Forging can operate on cold or hot materials cold working is conducted at temperatures of at 480degree Celsius to 780, and hot operating at above the recrystallisation temperature of the material getting forged.

Normally applying strenuous and heavy deformation to cold steel cracks the steel but by sustaining compression at all points this does not happen. By using little components cold forging can create a final shape with stainless steel supplying they are effectively lubricated and contained. Cold forging tends to make goods precisely to their shape which can’t be accomplished with hot forging, and given that with cold forging components can often be formed in 1 blow production prices are really higher. Cold forging is a wonderful alternative to precision machining simply because it cuts the machining time fairly considerably which for a business means lowers expenses on making components and a quicker price at which they can be supplied.

Robert Cooke, chairman of a precision machining organization, states that production time has been reduce from two minutes to a handful of seconds. The timing and the method involved in cold forging is dependent on the material becoming employed but generally there are 6 measures that take spot, pre-type production, upsetting, annealing, lubrication, cold forging, and the finishing machining. Cold forging has numerous benefits over the standard precision machining techniques such as modest batch sizes can be accomplished making use of rapid change tooling, monitoring the process of the methods for top quality control, fine surface finish, high productivity, and so on and so on. With these dramatic benefits it is thought that cold forging will become even far more common amongst the precision machining industry over the years to come

If you are searching for a precision machining firm take a look at ITI-Manchester’s web site.

Uncover More Machining Forged Parts Articles

Huge Precision Machining Capabilities

Large precision machining Capabilities.

Cool Precision Machining Components pictures

Some cool precision machining parts photos:

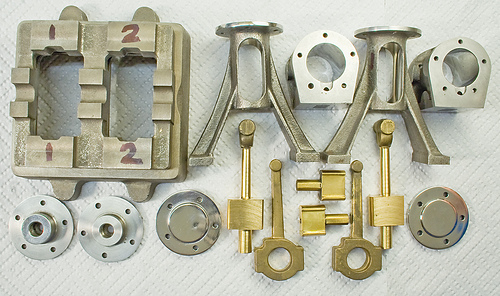

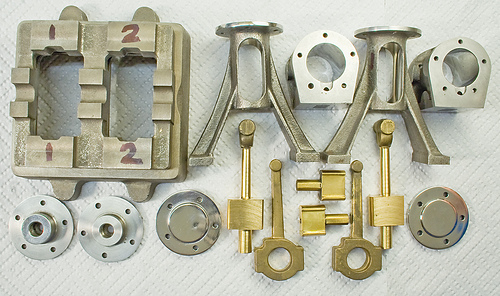

A Disassembly of parts

Image by tudedude

Some of the parts of the Stuart D10 Twin Cylinder Steam engine. Some parts are completely machined some are awaiting their fate in the near future.

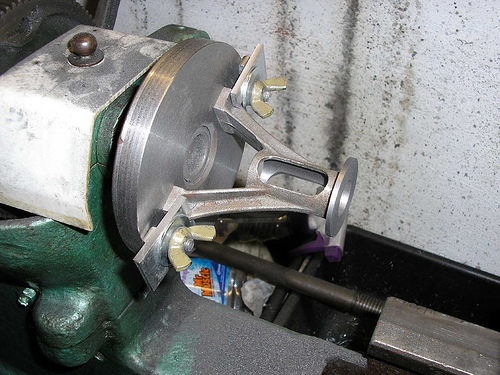

Machining a Standard bore and leading

Image by tudedude

Second part of machining the requirements

Combo five-axis CNC Cylinder Head & Block Machining center: The CENTROID A560 Port/Block

CNC port cylinder heads, blueprint and CNC machine engine blocks and make all types of parts with one machine the CENTROID A560. See the machine in action po…

Video Rating: / 5

Newest Precision Cnc Machining Services News

Busch Precision buys Maintenance Service Corp. of West Allis

Busch Precision Inc. has purchased the machine tool service and repair, and CNC retrofitting company of Upkeep Service Corp. of West Allis. Based in Milwaukee, Busch Precision will operate the Maintenance Service Division out of Busch's headquarters …

Read a lot more on Milwaukee Business Journal

Existing pulse

Combining Rollomatic's R&D, purchasing power, and other sources, Strausak continues to develop precision CNC grinding machines, such as the 5-axis Fleximat. As one of the very first users of the NUM handle and Numroto tool grinding … specializes in CCM …

Read much more on Today’s Healthcare Developments

6060 Aluminium Bracket Machining.

Far more 6060 Aluminium machining on the trust old Chinese 3020 CNC machine, this time it is a curved washer/bracket issue for a house produced German Equatorial Mount…

Video Rating: 5 / five

Trojan Custom Arch – Machining Components 1

Just machining some elements for a custom arch I’m developing for my 10m Trojan project.

Video Rating: / 5

Making several tiny wood elements at Custom Wood Products in Charles City, Iowa.

Aluminum Polishing soon after CNC Machining at Jevny Technology in China

Aluminum Polishing after CNC Machining at Jevny Technologies in China Jevny Technologies is a Complete Service Rapid Prototype,Manufacturing and OEM company located …

Video Rating: 1 / five