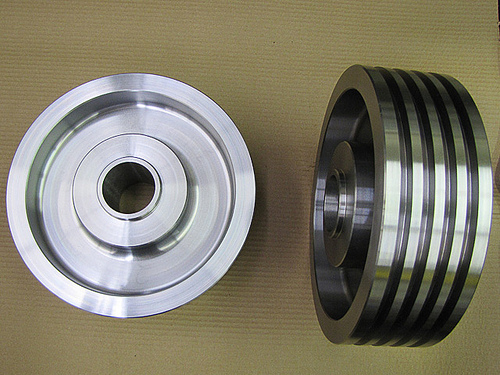

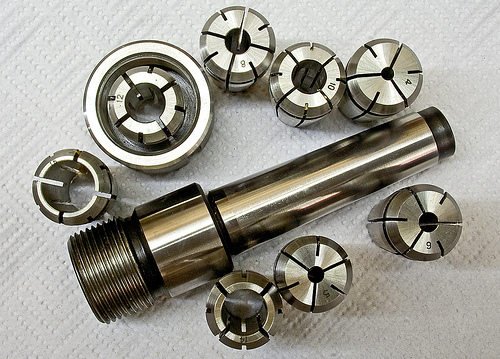

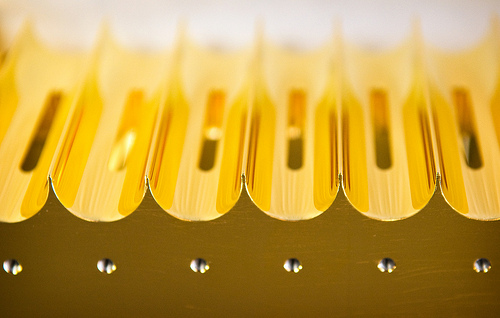

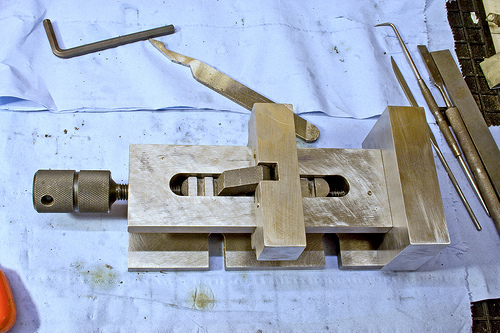

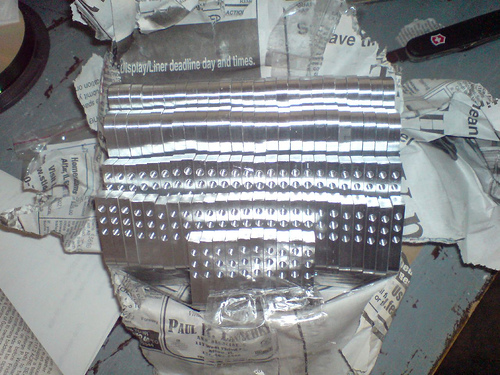

These days market is studded with numerous high precision turned & China machined components. The range consisting of Wiper Shaft, CNC China Machining and even Inspection Infrastructure for automobiles, electric motor and many more. Each product speaks of its quality, durability and higher performance.

The entire range is manufactured as per international quality norms and standards. These products are checked on different parameters to ensure dimensional accuracy, product conformity, excellent performance and higher functional life. We offer the products in bulk quantity as suggested by our esteemed clients around the world.

For optimum production, China manufacturing units are fully equipped with modern machinery and latest technology. Moreover, designing of the products is done in the state of the art research & development department. These designs are not just developed by our highly qualified technocrats but also with the help of our wise clients who constantly provide us their valuable suggestions. Moreover, best quality management system maintained in the industries help in offering excellent product range to huge clients located in different parts of the world.

Besides, excellent after sales services are provided to meet the varied requirements of the clients in well specified manner. This helps the firms to establish better relation with their honorable clients for mutual benefits.

Excellent Quality Management System

A product is known by its quality. As quality improves, the sale of the product goes higher and higher. Every industry has its own set of well defined parameters to test the products. These parameters basically include quality, performance and durability of the range. By implementing product control plan, inspection of raw materials (incoming) and pre delivery inspection, higher growth targets are achieved.

Moreover, a team of highly qualified & experienced professionals assist in delivering smooth and quality service. Owing to quality inspection & service, higher client satisfaction is attained in a systematic order. So you get a good number of precision engineered turned & China machined components that include CNC China Machining, Wiper Shaft and Inspection Infrastructure for electric motor, automobiles and many more. All these products require less maintenance and have longer service life. So here quality management system has a wider role.

Product Range

The entire range of CNC China Machining, Wiper Shaft and Inspection Infrastructure are manufactured in ISO 9001 : 2008 certified units. These high precision turned /machined components also consists of China Grinding, China Turning, Drilling, China Machining, Tapping, Thread Rolling, and more. These products are widely used in numerous China engineering and automotive based Industries. In addition to this, superior after sales services are also provided to fulfill the needs of the customers and keep them fully satisfied & happy. This helps the manufacturers build better relation with their customers. Several parameters on which the range is checked comprise

Dimensional Accuracy

Product Conformity

Highest Degree Of Performance

Longer Functional Life

All these are universally accepted norms & parameters to assure the clients get superior product range and best of services as long as they require. These pre defined parameters help in providing optimum client satisfaction. These products are available in custom specifications and at the competitive price range for various industrial and non industrial utilities.

Informative articles are provided by the writer cum journalist. His valuable write up – High Precision Turned And China Machined Components offers all information regarding CNC China Machining, Wiper Shaft and Inspection Infrastructure for numerous China engineering and automotive based Industries. So read this!