http://www.deltexmachineshop.com At Deltex Machine Shop Inc., we offer you our consumers a one particular-cease shopping encounter. Doing enterprise with us signifies you no longer…

Video Rating: 5 / five

Machine

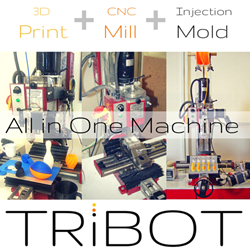

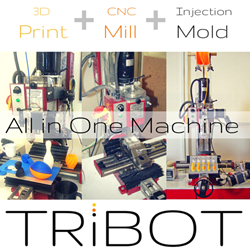

New Multi-Function Machine Capable of 3D Printing, CNC Milling, and Injection Molding

Nampa, ID (PRWEB) September 18, 2014

View the Kickstarter here.

The TRiBOT fills the void that currently exists among light duty 3D printers and heavier duty machining and injection molding equipment. The TRIBOT desktop workshop machine can take concepts from prototype to production without investing in three different machines at far more than 3 times the cost.

It is the 1st machine to offer the distinctive 3-in-one particular manufacturing capabilities of 3D printing, CNC milling and auto-injection molding. Unlike other 3D printing machines, the TRiBOT is constructed on a solid 130 lb iron frame. It is capable of printing detailed prototype models while nevertheless preserving the practical use as a CNC Mill or manual mill to shape solid steel with ease.

The TRiBOT is the ultimate tool for creators with wonderful suggestions who do not have access to the multiple machines, tools and technologies required to bring their ideas to life. The TRiBOT provides the special potential to create their ideas and prototype them, then ideal them down to the finest detail and then make them. All with 1 machine.

John Rule, President of Luminar Merchandise in Nampa, Idaho says “The TRiBOT is the most versatile machining tool that offers creators the ultimate tool for bringing an notion to life.”

Ron Steele, chief engineer comments “Anybody who has ever tried to turn an thought into a finished product knows how difficult it can be to get from prototype, to perfecting, to production stages. You typically need not just one particular, but an assortment of extremely costly specialized tools to travel via the creation process.” The TRiBOT offers the versatility of three machines with a considerably smaller footprint and price tag than would usually come with buying three machines capable of the very same functions.

The Kickstart campaign aims to raise $ 30,000 in 45 days on the crowd-funding website, by reaching entrepreneurs, inventors, artists, clothes designers, jewelry designers, engineers, schools, labs, manufacturing shops, or just a machine hobbyist who desires the most versatile machine obtainable. The campaign launched September 17th and ends on November 1st.

Learn far more about the group right here.

Luminar Goods is a small manufacturing firm located in the stunning Idaho Treasure Valley appropriate outdoors of Boise. Luminar plans to send waves by way of the little scale manufacturing planet with the the TRiBOT. Passionate about supplying inventors, designers, engineers, artists, and anybody with an concept the tools essential to make it a reality.

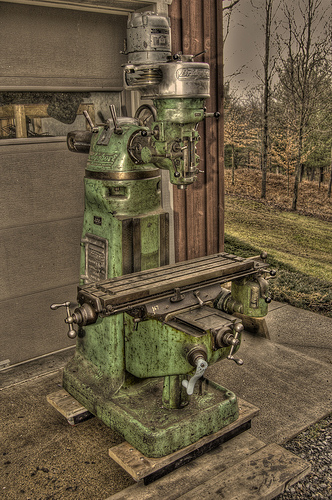

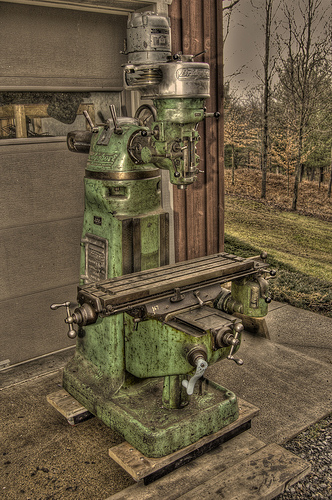

Bridgeport milling machine (constructed in 1948)

Verify out these vertical milling machine pictures:

Bridgeport milling machine (built in 1948)

Image by Darron Birgenheier

The a single-ton monster poses for its portrait.

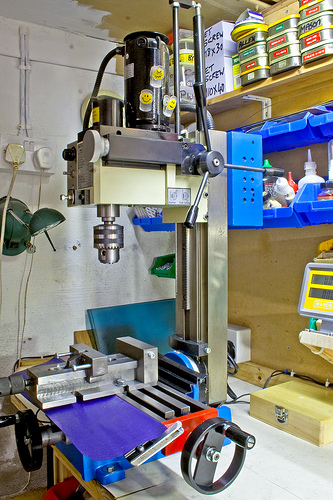

Mini Mill Complete Length

Image by tudedude

Spend special interest to the unfinished paint perform on the ceiling 🙂

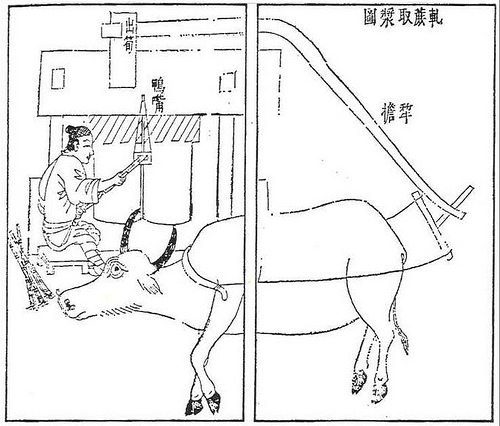

Crushing cane with an ox-powered vertical-toothed roll crusher, 1637

Image by Marcel Douwe Dekker

Supply: Song Yingxing (1637) Tiangong Kaiwu, portion three on agriculture and milling processes

Studying to operate a cutting machine, these two NYA workers receive education to match them for critical function, Corpus Christi, Texas. Right after eight weeks they will be eligible for civil service jobs at the Naval Air Base (LOC)

A couple of good machined metal parts images I identified:

Understanding to work a cutting machine, these two NYA personnel obtain training to fit them for essential work, Corpus Christi, Texas. After eight weeks they will be eligible for civil service jobs at the Naval Air Base (LOC)

Image by The Library of Congress

Hollem, Howard R.,, photographer.

Studying to function a cutting machine, these two NYA personnel acquire training to fit them for essential work, Corpus Christi, Texas. Following eight weeks they will be eligible for civil service jobs at the Naval Air Base

1942 August

1 transparency : color.

Notes:

Title from FSA or OWI agency caption.

Transfer from U.S. Office of War Info, 1944.

Subjects:

United States.–Navy

Airplane sector

Planet War, 1939-1945

Civil service

Laborers

Air bases

United States–Texas–Corpus Christi

Format: Transparencies–Colour

Rights Information: No recognized restrictions on publication.

Repository: Library of Congress, Prints and Photographs Division, Washington, D.C. 20540 USA, hdl.loc.gov/loc.pnp/pp.print

Portion Of: Farm Safety Administration – Workplace of War Information Collection 12002-18 (DLC) 93845501

Common info about the FSA/OWI Color Photographs is accessible at hdl.loc.gov/loc.pnp/pp.fsac

Higher resolution image is accessible (Persistent URL): hdl.loc.gov/loc.pnp/fsac.1a34872

Get in touch with Quantity: LC-USW36-53

1911 Avery 40-120 HP Steam Traction Engine (at the Buckley Old Engine Show) [BOES two/9]

Image by jimflix!

Self-propelled steam-powered traction engine (steam tractor) built in 1911 by the Avery Business in Peoria, Illinois.

Some history: This was a single of the most uncommon traction engines of the day. With its renowned under-mounted engine, looking more like a railway locomotive than a standard steam traction engine, it attracted a lot of focus when it hit the agricultural market place in the early 20th century. The giant 40 HP model (above) could pull massive gang plows by means of tough prairie sod.

The Avery below-mounted engine was excellent for other jobs in addition to plowing. “Is it plowing, seeding, shelling, sawing, ensilage cutting, grain hauling, road grading, residence moving or other operate? No matter what the function is we can supply you with the correct sort of an engine or tractor to do the perform,” mentioned the Avery Firm.

For far more information about these Avery steam traction engines, see this report. Right here are a handful of quick videos of this running and operating at the show: video 1, video 2, video three.

Steam traction engines had been used in two ways:

1. “on the belt" utilizing the steam engine to power stationary farm machinery (such as a threshing machine) by signifies of a continuous leather belt driven by the flywheel.

2. "on the drawbar" as a steam tractor pulling heavy loads, specifically plowing a fields. A 65 to 85 horsepower engine with an eight furrow plow could plow 25 to 35 acres in day, compared to about a single acre a day by horse.

The smaller horsepower number, 40 HP in this case, is the "on the drawbar" pulling power of the tractor. The bigger quantity, 120 in this case, is the "on the belt" power of the engine at the flywheel.

Note that steam engines have some advantages more than internal combustion engines in that they have full torque all the way down to zero RPM. You can commence and quit the engine with the plow in the furrows with out shifting gears or even employing the clutch.

Back to the show: The steam tractors are probably the coolest issue at the show, and there are Several of them!

Taken at the annual Buckley Old Engine Show in Buckley, Michigan (on M-37 south of Traverse City). By the way, this is a single of the greatest run outside events I’ve ever attended! And it really is entertaining for the complete family. When was the final time you rode a train pulled by a true steam locomotive…?! And here’s The Buckley Old Engine Show song written by Kim Carson-Colley! The video offers you a taste of a bit of what’s there.

I left this quite massive so you can zoom in to see much more detail.

Quiz — see if you can uncover the two bull dogs. Hint: they are not true ones. This tractor is portion of Avery’s Bull Dog line with a "Teeth Speak" motto. Here’s the logo for this line, so that’s an additional clue.

(Click on image to view on black — appears better.)

Cnc Lathe Machine

Lathes are created for precise machining of comparatively hard materials. They are originally made to machine metals nonetheless, with the advent of plastics and other supplies, and with their inherent versatility, they are employed in a wide variety of applications, and a broad variety of materials. These rigid machine tools eliminate material from a rotating operate piece by means of the (usually linear) movements of various cutting tools, such as tool bits and drill bits.

A lathe shapes material by rotating it rapidly while pressing a fixed cutting or abrading tool. These days, lathes equipped with laptop numerical handle (CNC) characteristics have a tendency to dominate the factory or machine shop floor. CNC lathe machinists operate these machines to aid fashion tools and goods.

CNC Lathes are quickly replacing the older production lathes due to their ease of setting and operation. They are designed to use modern day carbide tooling and totally utilize modern processes.

The machine is controlled electronically by way of a computer menu style interface, the system may possibly be modified and displayed at the machine, along with a simulated view of the procedure. The setter/operator needs a higher level of talent to carry out the process, nevertheless the expertise base is broader compared to the older production machines exactly where intimate understanding of every single machine was deemed crucial. These machines are often set and operated by the very same person, where the operator will supervise a small number of machines (cell).

The design and style of a CNC lathe has evolved yet once more nonetheless the fundamental principles and components are nevertheless recognizable, the turret holds the tools and indexes them as needed. The machines are usually totally enclosed, due in massive element to occupational overall health and safety (OH&S) troubles.

With the advent of cheap computers, cost-free operating systems such as Linux, and open source CNC software program, the entry price tag of CNC machines has plummeted.

When a shop desires to shape a portion utilizing a CNC lathe, a programmer will first create a set of machining guidelines and translate them into a laptop aided/automated manufacturing (CAM) program for the machine to adhere to. Then a CNC lather operator downloads the system, sets up the lathe, begins the machine and monitors it until the job is total.

The author is related with IPFonline

http://www.ipfonline.com is India’s No. 1 Industrial Product Finder. The portal is a veritable storehouse of information on industrial goods/solutions.

Precision Grinding Machine Exporter,Manufacturer,Gujarat

Purchase Precision Grinding Machine from PITRODA UTILITY INDUSTRIES. Exporter, Manufacturer & Supplier of Precision Grinding Machine Precision Grinding Machines,P…

Video Rating: / five

PMP – Precision Machine Components Poland

PMP – Precision Machine Parts Poland.

Video Rating: / 5

precision machine parts made by Joinconn, www.dgjuwang.cn.for precision machine components more information pls. speak to lisa@dgjuwang.cn , Skype ID: sales7-juwang Te…

Trace-A-Matic, Large Portion CNC Machine Shop Milling, Cost-Efficient, High Production Machining

Huge parts CNC Machining by Trace-A-Matic. TAM is a leading CNC Machining Job Shop in Milwaukee, Wisconsin. Properly-known for very-engineered CNC machined pa…

Video Rating: 5 / 5

www.cadcam123.com. Powerful and effortless in use 2D two,5D cadcam software for NC milling and lathe jobs. Free of charge downloads trial version. Import and export of DXF and…

Video Rating: 5 / five

Tree Journeyman 325 CNC milling machine – Part 1

First look at a 1986 Tree Journeyman 325 CNC mill, troubleshooting some servo drive problems, and making a initial part. Original brochure for the machine: htt…

The new age of CNC Horizontal Machine

As we know that the CNC milling machine can be divided into two categories horizontal and vertical primarily based on the placement of the cutting tool. Needless to say the vertical primarily based machine will execute all operations vertically and similarly horizontal will carry out it horizontally. Bigger sized machines are also obtainable to meet the specifications of businesses manufacturing larger components. These machines are employed to consist of three, four and 5 axis machining centers. It is really clear that the 5 axis machines are the quickest and perform precise milling operations compared to the other two. CNC Milling is a cutting approach in which material is removed from a block by a rotating tool. Lots of makers use CNC Horizontal Machining for buyers in a selection of industries, such as aerospace, automotive, healthcare and defense. For these industries and other individuals, we create engine elements, custom and mold tooling, complex mechanisms and enclosures, as well as customized parts.

The need to have of Horizontal Milling Machine

Individuals constantly employed the traditional CNC milling machine as they did not had any options to make their manufacturing enterprise a worthy 1. They actually needed a excellent number of workers to run these machines. The traditional kind of milling machine are manually operated, it needs lot of time, and effort. The latest automated version can increase the speed of cutting in comparison to manually operated machines. Usually instances the material that needs to be cut is stiff and thick which can’t be made-up with manually operated machines. The horizontal milling machine simply drills any material, saving lot of time and overhead expense occurred due to material wastage. In a lot of industrial applications, it is essential to create identical finished merchandise, the sophisticated CNC machining offers with exact and correct cutting, creating the item attractiveand growing the profit turnover of the firm.

Horizontal machining is quite expense successful and produces higher top quality items. This variety of milling machine is created to do it all with a huge assortment of tough supplies. The method is quick and needs minimal setups along the way. This decreases the developing labor fees that frequently accompany any manufacturing environment. The finishes are superior and the final product comes out just as planned. Several horizontal mills are completely automated and need no human intervention to operate correctly. All the programming is accomplished ahead of time so that absolutely nothing is left to possibility. This reduces processing time by about one fourth of the part and most importantly due to the fact manual labor is no longer needed.

Comparison amongst Horizontal and Vertical CNC machines

Horizontal milling machines ado function like Vertical milling machines but they certainly have some standard variations. A horizontal mill operates in much the identical way as a vertical milling machine does. However, horizontal mills have overhead arm supports and cutters that are arbor driven. Horizontal mills demand you to pay a tiny much more attention to safety and maintenance rules so that significant injuries as cutters are always sharp. So, makers should sustain security measures for their workers in the factory for a better output.

For more information about CNC machining, Please visit http://www.undergearengineering.com/