Colorado Springs, CO (PRWEB) September 23, 2014

Colorado Springs-based Diversified Machine Systems (DMS), and subsidiary brand Freedom Machine Tool, will exhibit two CNC routers at the SOCOM Expo in a 10’ x 20’ booth from the Freedom Machine Tool line – the Orthorout 4×4 and Workplace Machining Center.

This is the inaugural year for The Southern Colorado Manufacturing (SOCOM) Expo and Conference, is an occasion in Colorado Springs that provides education about the region’s expanding manufacturing company, as properly as possibilities for companies, suppliers, service providers and educational institutions to connect. This expo was developed for National Manufacturing Week by a group of nearby manufacturing firms who are seeking new avenues to create neighborhood awareness about the rapidly developing manufacturing sector. Not only does the expo concentrate on facilitating organization-to-enterprise relationships within the area, but it also presents manufacturing to students as a viable profession path. The expo currently estimates to host over 1,800 students from middle school via college.

As 1 of the organizations involved in this partnership and a promoter of these initiatives, DMS has signed on as an Industry Host Sponsor and will also be offering tours of their World Headquarters on National Manufacturing Day – Friday, October 3rd.

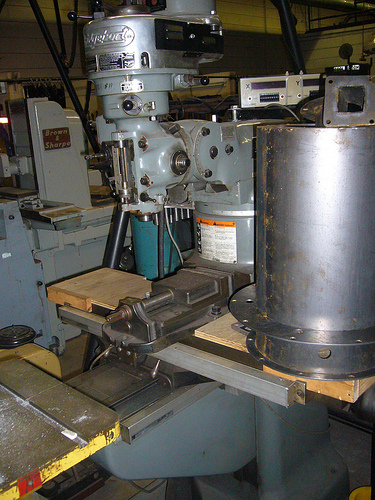

At their SOCOM booth, DMS will be exhibiting the Freedom Machine Tool Orthorout 4×4 – a CNC Router developed for the orthotic market and utilized by custom health-related facilities. The other machine on display will be the new Workplace Machining Center, which is so compact and portable that it’s capable to roll by way of a common doorway. Live demos will be run both days on the Workplace Machining Center, including the live machining the plaque awards for the winners of the Awards Ceremony.

The SOCOM Expo kicks off National Manufacturing Week with setup and networking on Monday, September 29th, and Expo and Conference spanning two complete days on Tuesday, September 30th and Wednesday, October 1st at the Freedom Economic Services Expo Center in Colorado Springs, CO.

Sponsored by the exact same nearby manufacturers and DMS is the displaying of the American Made Film (http://www.TheAmericanMadeMovie.com) at the 21st Century Library on Wednesday evening at 6pm – open to the public.

On Thursday, Pikes Peak Community College is hosting Manufacturing Panel Forums to encourage students to explore the tours on Friday, National Manufacturing Day which can be found at MFGDay.com. DMS is hosting two 1-hour tours starting at 9am to 11am.

Understand a lot more about the Expo at SOCOMExpo.com and a lot more about DMS at DMSCNCRouters.com.

ABOUT DIVERSIFIED MACHINE SYSTEMS

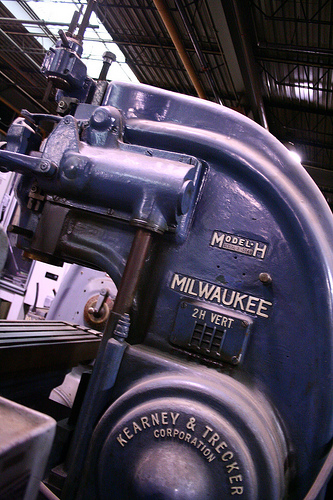

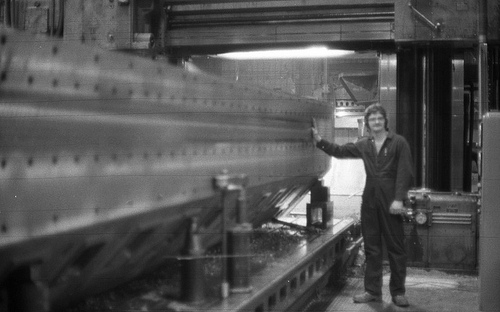

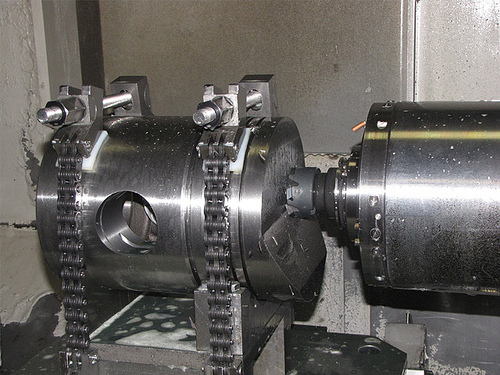

Diversified Machine Systems (DMS) was lately named a 2014 Colorado Business to Watch and awarded the 2013 Regional Enterprise Excellence in Manufacturing Award. With more than 30 years of innovation and sector expertise as an Original Gear Manufacturer, DMS’ line of CNC routers and machining centers are routinely utilised on supplies such as wood, composites, aluminum, steel, plastics, and foams. Renowned for top quality and precision, our advanced machining centers are engineered to increase efficiency and productivity, whilst preserving the high quality and precision our customers have come to anticipate from DMS.

Be positive to connect with us socially for the most existing news:

Twitter.com/DMSCNCRouters

YouTube.com/DMSCNCRouters

Instagram.com/DMSCNCRouters

Facebook.com/DMSCNCRoutersandMachineCenters

Plus.Google.com/+DMSCNCRoutersandMachineCenters

Locate Much more Cnc Engineering Press Releases