Check out these prototype china pictures:

YF-18A NAWS China Lake Museum 160775

Image by Jerry Gunner

The prototype Hornet, preserved at China Lake.

Rapid Prototyping China

Check out these prototype china pictures:

YF-18A NAWS China Lake Museum 160775

Image by Jerry Gunner

The prototype Hornet, preserved at China Lake.

Some cool china mechanical engineering pictures:

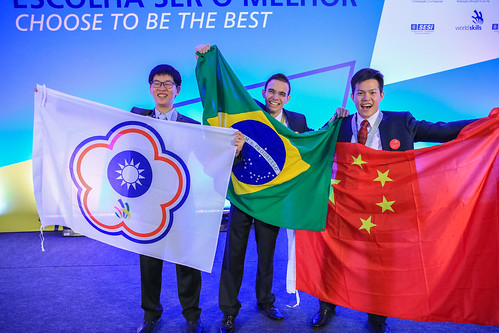

WSC2015_closing_MM-7524

Image by WorldSkills

WSC2015_ClosingCeremony_BB-5587

Image by WorldSkills

WSC2015_ClosingCeremony_BB-5580

Image by WorldSkills

Some cool sheet metal components china images:

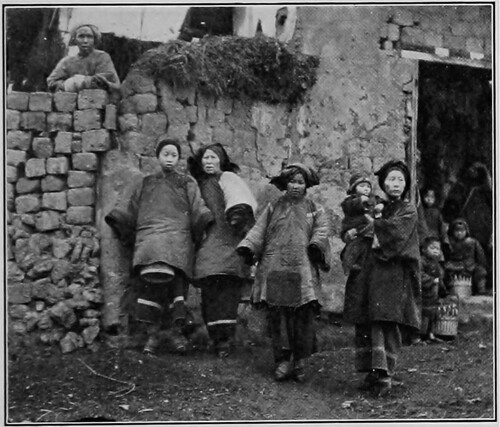

Image from web page 64 of “Sunset” (1898)

Image by Net Archive Book Pictures

Identifier: sunset74jansout

Title: Sunset

Year: 1898 (1890s)

Authors: Southern Pacific Company. Passenger Department

Subjects:

Publisher: [San Francisco, Calif. : Passenger Dept., Southern Pacific Co.] Menlo Park, CA : Sunset Publishing Corporation

Contributing Library: Web Archive

Digitizing Sponsor: World wide web Archive

View Book Page: Book Viewer

About This Book: Catalog Entry

View All Photos: All Images From Book

Click here to view book online to see this illustration in context in a browseable on the web version of this book.

Text Appearing Before Image:

arently altering it, andat the identical time adding to the appear-ance of the fireplace unit? To find outhow a lot smaller the opening shouldbe, experiment by employing a massive sheet ofcardboard to cover part of the mouth,until you uncover the proportion that ef-fectively stops the smoking. (If indoubt as to proportions, send to Wash-ington, D. C, for Farmers BulletinNo. 1230.) An economical and sensible methodis to build a grate and fender as illus-trated here. The minimum height ofthe grate and fender is 14 inches, and,as the height of the opening in the aver-age fireplace is in between 30 and 34inches, this really cuts the openingdown to about a third its original size.Any machine-shop worker can makesuch a grate. The fender is most attrac-tive, created out of hammered copper andwrought iron if no one particular is found whodoes this function, have a mechanic makeone out of sheet metal. The fender isneeded not only for appears, but in orderto decrease the draft under the fire.Being loose, it can be easily removed

Text Appearing Soon after Image:

although one cleans out the ashes andsweeps the hearth. The front of the grate is created of% by li/j-inch soft steel. The bottombars of the grate are reduce from I/2 by114-inch bars, and are spaced % inchapart, resting at front and rear on two by2-inch angle iron. If the grate is 20inches or more than in depth, it is better tohave the center supported by anotherangle iron. The center grate bars areleft loose, so that they can be turnedover or replaced in case of warping. Inmost fireplaces the back is narrowerthan the front, in which case the trian-gular sides of the bottom of the grate(see sketch) can generally be made outof a piece of y^ by 6-inch sheet ironcut at an angle. It will be discovered veryconvenient to have the grate resting ontwo or much more U-shaped legs for slidingit into the fireplace opening, though itcan be supported on bricks. Rivets(five/16-inch size) are utilised and %-inchholes are drilled which ought to take careof any inaccuracies in lining up theholes. The grate must be set in threeinches fro

Note About Images

Please note that these photos are extracted from scanned page images that may have been digitally enhanced for readability – coloration and appearance of these illustrations may not completely resemble the original operate.

Verify out these china prototypes pictures:

Ubco Assembly

Image by locusresearch

2×2 in assambly, China 2015

Check out these precision engineering images:

Boxed Set – Drills and taps

Image by tudedude

View On Black

A Naked Mini Mill

Image by tudedude

Mini Mill striped to it’s bare essentials, at least as far as the milling table is concerned. The machining is good where it wants to be nice.

Check out these rapid prototyping in china photos:

Protei 011 “Optimist” Kit

Image by cesarharada.com

scoutbots.com/

protei.org

A handful of nice mechanical engineering china images I located:

Decoding Cancer

Image by Planet Economic Forum

Jeffrey M. Drazen, Editor-in-Chief, The New England Journal of Medicine, USA, Cao Xuetao, President, Chinese Academy of Health-related Sciences, People’s Republic of China, Katrine Bosley, Chief Executive Officer, Editas Medicine, USA and Lydia Sohn, Professor, Mechanical Engineering, University of California, Berkeley, USA at the World Economic Forum – Annual Meeting of the New Champions in Dalian, People’s Republic of China 2015. Copyright by World Economic Forum / Sikarin Fon Thanachaiary

Image from web page 82 of “Railway mechanical engineer” (1916)

Image by World wide web Archive Book Pictures

Identifier: railwaymechanica96newy

Title: Railway mechanical engineer

Year: 1916 (1910s)

Authors:

Subjects: Railroad engineering Engineering Railroads Railroad automobiles

Publisher: New York, N.Y. : Simmons-Boardman Pub. Co

Contributing Library: Carnegie Library of Pittsburgh

Digitizing Sponsor: Lyrasis Members and Sloan Foundation

View Book Page: Book Viewer

About This Book: Catalog Entry

View All Photos: All Images From Book

Click right here to view book on the web to see this illustration in context in a browseable on the internet version of this book.

Text Appearing Ahead of Image:

83 83 1,949 1916 1,732 70 1,802 37 37 1,839 1917 1,924 31 1,955 45 45 two,000 1918 1,480 92 1,572 1 1 1,503 1919 306 85 391 160 160 551 1920 1.272 168 1,440 ■Includes Canadian output. ■i^Consists of Canadian output and equipment constructed in business shops. vehicle list only Ijecause they will presumably be operated in pas-senger trains. South America and China have been the biggest foreign buy-ers. The Argentine Government ordered 53, the ChileanState Railways ordered ten, and railways in Colombia, 28.The Tientsin-Pukow of China gave us an order for 45. Itis noteworthy that in the case of the Chilean and Tientsin-Pukow automobiles, all-steel construction was specified. Of the Total of 1,739 passenger automobiles owned by the Pacificsystem of the Southern Pacific, 890 are all-steel, 812 are woodand 37 are of steel underframe construction. The very first steelcoach, constructed as an experiment, was completed in the Sacramentashops of the firm in 1906, and no wooden passenger carshave been constructed by the company given that 1910.

Text Appearing Following Image:

The First Steam Turl^ine Locomotive THE first steam turbine locomotive actually constructedwas created in 1907 by Professor Belluzzo of theEcole Polytechnique, Milan, Italy, and given its mitialtrial run in 1908 at the performs of the Societe AnonymeOfficine Meccaniche, Milan. An old four-wheel regular gage switching locomotive wa.,emploved for the purposes of the test, the clinders and otherparts of the reciprocating engine getting removed and turbmesand npcessar manage mechanism substituted. This engmehad 47ii-in.driving wheels, a wheel base of 6 ft. six)4 in., aheating surface of 646 sq. ft. and carried a boiler pressureof 145 lb. per sq. in. The weight soon after conversion was 57,300 lb. . . J Four turbines were emploved, one turbine getting gearedto every enri of the two a.xles. Steam was admitted from theboiler to the fonvard turbine on the proper hand side, andafter passing through this turbine it was additional expandedthrough the rear turbine on the right hand side, then passedto the left

Note About Images

Please note that these photos are extracted from scanned page pictures that might have been digitally enhanced for readability – coloration and appearance of these illustrations might not perfectly resemble the original work.

Some cool sheet metal china pictures:

Image from web page 100 of “An American engineer in China” (1900)

Image by World wide web Archive Book Photos

Identifier: cu31924023226081

Title: An American engineer in China

Year: 1900 (1900s)

Authors: Parsons, William Barclay, 1859-1932

Subjects: Parsons, William Barclay, 1859-1932 Railroads

Publisher: New York, McClure, Phillips & co.

Contributing Library: Cornell University Library

Digitizing Sponsor: MSN

View Book Page: Book Viewer

About This Book: Catalog Entry

View All Pictures: All Photos From Book

Click here to view book on the web to see this illustration in context in a browseable online version of this book.

Text Appearing Ahead of Image:

set, I donot know, but the last we saw of that man he washugging his rind like a ti-easure. Before we hadseen the last of his horse, nonetheless, we felt that ifthe pumaloe rind had constituted the complete ofthe acquire-cost we still need to have been thelosers. It is surprising how closely the men and women in onesection of the country pattern after those else-where, when one particular remembers the lack, almostabsolute lack, of intercommunication. But inspite of the basic sameness, which perhapsappears higher than it is on account of the uni-formity in physiognomy of the men and women, with theMongolian coloring and jet-black hair, there weremany pecuHar customs which appeared to belocalized, as numerous of them were found only in Chapter III: Hu-nan, the Closed Province 95 tiny districts, and travelled Chinese who accom-panied me, stated that they had in no way prior to seensimilar things elsewhere in the empire. Of thesethe most singular was the carrying of tiny bam-boo baskets lined with sheet metal and filled with

Text Appearing Soon after Image:

A Peculiar Custom by Chinese Women of Wearing Heat-ing-Baskets hot wood-ashes. Such baskets the girls in onelocality suspend from a belt beneath their shortblouses. Occasionally the baskets are worn infront, often behind, and occasionally in bothplaces, according, apparently, to the fancy of thewearer. Youngsters also produced use of the heating 96 An American Engineer in China apparatus, but men only seldom. No matter howworn, the effect in all situations was both extraordi-nary and comical. To get a photograph of Chi-nese ladies is almost as hard as to photographa herd of wild deer. Girls are supposed tokeep away from any man, and of course a foreignman is specially terrible. The picture of thewomen and their baskets was obtained by cau-tious stalking behind some Chinese, even though theirattention was attracted by 1 of the members ofmy employees. The immediate after the shutter droppedthe group had scattered. In farming strategies the Chinaman in the inte-rior is, of course, centuries behind. His gra

Note About Images

Please note that these images are extracted from scanned page photos that may possibly have been digitally enhanced for readability – coloration and look of these illustrations may not completely resemble the original work.

Image from web page 142 of “The art of lead burning a practical treatise explaining the apparatus and processes” (1905)

Image by Internet Archive Book Images

Identifier: artofleadburning00fayc

Title: The art of lead burning a practical treatise explaining the apparatus and processes

Year: 1905 (1900s)

Authors: Fay, C. H

Subjects: Lead burning

Publisher: New York, D. Williams company

Contributing Library: The Library of Congress

Digitizing Sponsor: The Library of Congress

View Book Page: Book Viewer

About This Book: Catalog Entry

View All Pictures: All Photos From Book

Click right here to view book on the internet to see this illustration in context in a browseable on-line version of this book.

Text Appearing Ahead of Image:

d just as forlead. Britannia metal is fast becoming the favoritelining for splash and drip boards on butlers pan-attempt sinks, as also for lining the function benches insaloons. It is soft enough to enable the most deli-cate china to be laid on it with no danger of chip-ping, and is also quite straightforward to preserve clean. It takesa high polish and constantly looks well. The methodof cutting the metal for a butlers pantry sink isshown in Fig. 51, the dotted lines showing theactual dimensions of the write-up to be covered,although the complete lines show the laps required tocover the edges of the board. This metal isharder than lead, and will not dress smooth withthe dresser. Any uneven spots have to be presseddown with a hot flatiron. The approach of turn-ing the edges is shown at a. The bending iron isheated and rubbed over the edge, progressively turn- THE ART OF LEAD BURNING. 139 ing the edges till they are at their suitable posi-tion. The iron must be constantly heated to in-positive the ideal final results, and if appropriately carried out no

Text Appearing Soon after Image:

cq CQ 1 140 THE ART OF LEAD BURNING. wrinkles will seem. A lined perform bench isalso shown in Fig, 52, which shows the methodof placing in the bar washer. The sheet metalmust be cut and fitted to its place and all theseams feasible ought to be soldered before placingthe metal in position. The edges must be tackedon the beneath side of the function, when practicable,with copper tacks. Sooner or later the blow pipe solderer will becalled upon to make repairs on Britannia metal,and will be shocked to discover that it will be impos-sible to solder the metal, owing to the excess ofmoisture beneath it. The greatest way to overcomethis, which is practically the only difficulty thatoccurs, is to reduce out a little square patch. Theedge can be cleaned and a patch of new metalcarefully fitted into the hole. When prepared to be-gin soldering, a piece of blotting paper ought to beinserted amongst the patch and board. Thispaper will absorb all the moisture and let theseam to be neatly soldered. The man who makeshimself

Note About Images

Please note that these images are extracted from scanned web page pictures that might have been digitally enhanced for readability – coloration and appearance of these illustrations could not perfectly resemble the original work.

Image from web page 620 of “Mechanical Contracting & Plumbing January-December 1912” (1912)

Image by Net Archive Book Images

Identifier: mechcontract1912toro

Title: Mechanical Contracting & Plumbing January-December 1912

Year: 1912 (1910s)

Authors:

Subjects: Air conditioning Refrigeration and refrigerating machinery Heating Plumbing

Publisher: Toronto : Maclean-Hunter Pub. Co.

Contributing Library: Fisher – University of Toronto

Digitizing Sponsor: University of Toronto

View Book Page: Book Viewer

About This Book: Catalog Entry

View All Photos: All Pictures From Book

Click right here to view book on-line to see this illustration in context in a browseable on-line version of this book.

Text Appearing Just before Image:

-■•mum We Can FurnishYour Requirements in All PLUMBING GOODS We handle a total line of Enameled Baths Enameled LavatoriesSinks and Laundry Tubs

Text Appearing Soon after Image:

Write us about ourVictorian China Lavatories. The James Morrison Brass Mfg.Company, Ltd. Producers and dealers in a completeline of Plumbing and Heating Supplies 93-97 Adelaide Street West TORONTO 19 Complete Course in Sheet Metal Work In prob. 23, plate 21, fig. 1 representsa pail, of which A-B is a boss, or rein-forcement on the deal with. The pattern is just a circle havingthe identical curve as the deal with, and iscut out to shape shown by fig. two, thenformed to shape by fig. three, and solderedto deal with. In prob. 24, fig. 1, is a strainer pail,the brest B is developed the exact same as thebrest on the watering pail, prob. 18,plate 20. To develop the spout A, continue theline C- any distance, and parallel to By L. W. KOSER this carry a line from the point V, asV-7. Draw a cross section of the spout fig.2, then divide it into equal spaces andcarry lines from exact same till they cut thelines O-V and C-V. Lay out a stretchout at correct anglesto C-O, as fig. three, and carry lines fromthe distinct points o

Note About Photos

Please note that these photos are extracted from scanned web page photos that could have been digitally enhanced for readability – coloration and look of these illustrations may not perfectly resemble the original operate.

A few good machining engineering photos I discovered:

:)*

Image by The hills are alive*

If you’ve got the time go genuinely large. It is worth it.

Electronic sound effects you can make with the Science Fair …

electronic bird

electronic cat

electronic bird with CdS

2 way electronic bird

chicken peeping

knocking noise

woodpecker sound

light controlled electronic harp

T-transistor toy organ

wireless electronic organ

light-music maker,

electronic metronome

electronic motorcycle noise

machine gun sound generator

sound effects generator

sleep inducer

Drilling for Terrestrial Heat

Image by Kecko

This mobile gear can drill to a maximum depth of 300 m. Now they go down to 165 meters. Lutzenberg, Switzerland, Oct 1, 2008.

Adjustable Reamer in Hand Chuck

Image by tudedude

A few nice china prototype manufacturing images I found:

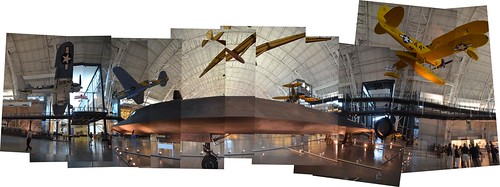

Steven F. Udvar-Hazy Center: Photomontage of SR-71 on the port side

Image by Chris Devers

Posted by means of e-mail to ☛ HoloChromaCinePhotoRamaScope‽: cdevers.posterous.com/panoramas-of-the-sr-71-blackbird-at…. See the complete gallery on Posterous …

• • • • •

See more photos of this, and the Wikipedia post.

Specifics, quoting from Smithsonian National Air and Space Museum | Lockheed SR-71 Blackbird:

No reconnaissance aircraft in history has operated globally in more hostile airspace or with such full impunity than the SR-71, the world’s quickest jet-propelled aircraft. The Blackbird’s efficiency and operational achievements placed it at the pinnacle of aviation technologies developments during the Cold War.

This Blackbird accrued about two,800 hours of flight time throughout 24 years of active service with the U.S. Air Force. On its final flight, March 6, 1990, Lt. Col. Ed Yielding and Lt. Col. Joseph Vida set a speed record by flying from Los Angeles to Washington, D.C., in 1 hour, four minutes, and 20 seconds, averaging three,418 kilometers (two,124 miles) per hour. At the flight’s conclusion, they landed at Washington-Dulles International Airport and turned the airplane over to the Smithsonian.

Transferred from the United States Air Force.

Manufacturer:

Lockheed Aircraft Corporation

Designer:

Clarence L. "Kelly" Johnson

Date:

1964

Nation of Origin:

United States of America

Dimensions:

Overall: 18ft five 15/16in. x 55ft 7in. x 107ft 5in., 169998.5lb. (five.638m x 16.942m x 32.741m, 77110.8kg)

Other: 18ft 5 15/16in. x 107ft 5in. x 55ft 7in. (five.638m x 32.741m x 16.942m)

Components:

Titanium

Physical Description:

Twin-engine, two-seat, supersonic strategic reconnaissance aircraft airframe constructed largley of titanium and its alloys vertical tail fins are constructed of a composite (laminated plastic-type material) to reduce radar cross-section Pratt and Whitney J58 (JT11D-20B) turbojet engines feature huge inlet shock cones.

Long Description:

No reconnaissance aircraft in history has operated in more hostile airspace or with such complete impunity than the SR-71 Blackbird. It is the quickest aircraft propelled by air-breathing engines. The Blackbird’s functionality and operational achievements placed it at the pinnacle of aviation technology developments during the Cold War. The airplane was conceived when tensions with communist Eastern Europe reached levels approaching a complete-blown crisis in the mid-1950s. U.S. military commanders desperately needed correct assessments of Soviet worldwide military deployments, especially close to the Iron Curtain. Lockheed Aircraft Corporation’s subsonic U-two (see NASM collection) reconnaissance aircraft was an able platform but the U. S. Air Force recognized that this comparatively slow aircraft was already vulnerable to Soviet interceptors. They also understood that the speedy development of surface-to-air missile systems could place U-2 pilots at grave threat. The danger proved reality when a U-2 was shot down by a surface to air missile more than the Soviet Union in 1960.

Lockheed’s very first proposal for a new high speed, higher altitude, reconnaissance aircraft, to be capable of avoiding interceptors and missiles, centered on a style propelled by liquid hydrogen. This proved to be impracticable simply because of considerable fuel consumption. Lockheed then reconfigured the design for traditional fuels. This was feasible and the Central Intelligence Agency (CIA), already flying the Lockheed U-two, issued a production contract for an aircraft designated the A-12. Lockheed’s clandestine ‘Skunk Works’ division (headed by the gifted design and style engineer Clarence L. "Kelly" Johnson) created the A-12 to cruise at Mach 3.two and fly effectively above 18,288 m (60,000 feet). To meet these difficult specifications, Lockheed engineers overcame many daunting technical challenges. Flying a lot more than three times the speed of sound generates 316° C (600° F) temperatures on external aircraft surfaces, which are sufficient to melt standard aluminum airframes. The design team chose to make the jet’s external skin of titanium alloy to which shielded the internal aluminum airframe. Two standard, but very powerful, afterburning turbine engines propelled this exceptional aircraft. These power plants had to operate across a huge speed envelope in flight, from a takeoff speed of 334 kph (207 mph) to far more than three,540 kph (2,200 mph). To avoid supersonic shock waves from moving inside the engine intake causing flameouts, Johnson’s team had to design and style a complicated air intake and bypass system for the engines.

Skunk Functions engineers also optimized the A-12 cross-section design and style to exhibit a low radar profile. Lockheed hoped to attain this by very carefully shaping the airframe to reflect as small transmitted radar power (radio waves) as possible, and by application of special paint developed to absorb, rather than reflect, those waves. This therapy became one particular of the 1st applications of stealth technologies, but it never ever totally met the design and style objectives.

Test pilot Lou Schalk flew the single-seat A-12 on April 24, 1962, after he became airborne accidentally in the course of higher-speed taxi trials. The airplane showed great promise but it needed considerable technical refinement ahead of the CIA could fly the initial operational sortie on May 31, 1967 – a surveillance flight more than North Vietnam. A-12s, flown by CIA pilots, operated as portion of the Air Force’s 1129th Particular Activities Squadron under the "Oxcart" system. Although Lockheed continued to refine the A-12, the U. S. Air Force ordered an interceptor version of the aircraft designated the YF-12A. The Skunk Functions, however, proposed a "specific mission" version configured to conduct post-nuclear strike reconnaissance. This method evolved into the USAF’s familiar SR-71.

Lockheed built fifteen A-12s, such as a unique two-seat trainer version. Two A-12s have been modified to carry a unique reconnaissance drone, designated D-21. The modified A-12s have been redesignated M-21s. These have been created to take off with the D-21 drone, powered by a Marquart ramjet engine mounted on a pylon in between the rudders. The M-21 then hauled the drone aloft and launched it at speeds high sufficient to ignite the drone’s ramjet motor. Lockheed also built three YF-12As but this kind in no way went into production. Two of the YF-12As crashed during testing. Only a single survives and is on display at the USAF Museum in Dayton, Ohio. The aft section of one of the "written off" YF-12As which was later employed along with an SR-71A static test airframe to manufacture the sole SR-71C trainer. One particular SR-71 was lent to NASA and designated YF-12C. Which includes the SR-71C and two SR-71B pilot trainers, Lockheed constructed thirty-two Blackbirds. The first SR-71 flew on December 22, 1964. Because of intense operational expenses, military strategists decided that the more capable USAF SR-71s ought to replace the CIA’s A-12s. These have been retired in 1968 following only 1 year of operational missions, mainly more than southeast Asia. The Air Force’s 1st Strategic Reconnaissance Squadron (portion of the 9th Strategic Reconnaissance Wing) took over the missions, flying the SR-71 beginning in the spring of 1968.

Soon after the Air Force began to operate the SR-71, it acquired the official name Blackbird– for the specific black paint that covered the airplane. This paint was formulated to absorb radar signals, to radiate some of the tremendous airframe heat generated by air friction, and to camouflage the aircraft against the dark sky at high altitudes.

Experience gained from the A-12 plan convinced the Air Force that flying the SR-71 safely essential two crew members, a pilot and a Reconnaissance Systems Officer (RSO). The RSO operated with the wide array of monitoring and defensive systems installed on the airplane. This gear integrated a sophisticated Electronic Counter Measures (ECM) program that could jam most acquisition and targeting radar. In addition to an array of advanced, high-resolution cameras, the aircraft could also carry gear developed to record the strength, frequency, and wavelength of signals emitted by communications and sensor devices such as radar. The SR-71 was made to fly deep into hostile territory, avoiding interception with its tremendous speed and higher altitude. It could operate safely at a maximum speed of Mach three.three at an altitude a lot more than sixteen miles, or 25,908 m (85,000 ft), above the earth. The crew had to put on stress suits related to those worn by astronauts. These suits were essential to shield the crew in the event of sudden cabin pressure loss whilst at operating altitudes.

To climb and cruise at supersonic speeds, the Blackbird’s Pratt & Whitney J-58 engines were developed to operate continuously in afterburner. Whilst this would seem to dictate high fuel flows, the Blackbird really achieved its ideal "gas mileage," in terms of air nautical miles per pound of fuel burned, during the Mach three+ cruise. A typical Blackbird reconnaissance flight may well call for several aerial refueling operations from an airborne tanker. Every time the SR-71 refueled, the crew had to descend to the tanker’s altitude, usually about 6,000 m to 9,000 m (20,000 to 30,000 ft), and slow the airplane to subsonic speeds. As velocity decreased, so did frictional heat. This cooling impact caused the aircraft’s skin panels to shrink significantly, and those covering the fuel tanks contracted so considerably that fuel leaked, forming a distinctive vapor trail as the tanker topped off the Blackbird. As quickly as the tanks had been filled, the jet’s crew disconnected from the tanker, relit the afterburners, and once more climbed to high altitude.

Air Force pilots flew the SR-71 from Kadena AB, Japan, throughout its operational career but other bases hosted Blackbird operations, also. The 9th SRW sometimes deployed from Beale AFB, California, to other areas to carryout operational missions. Cuban missions had been flown straight from Beale. The SR-71 did not start to operate in Europe until 1974, and then only temporarily. In 1982, when the U.S. Air Force primarily based two aircraft at Royal Air Force Base Mildenhall to fly monitoring mission in Eastern Europe.

When the SR-71 became operational, orbiting reconnaissance satellites had currently replaced manned aircraft to collect intelligence from web sites deep inside Soviet territory. Satellites could not cover each and every geopolitical hotspot so the Blackbird remained a crucial tool for global intelligence gathering. On numerous occasions, pilots and RSOs flying the SR-71 provided data that proved vital in formulating profitable U. S. foreign policy. Blackbird crews supplied crucial intelligence about the 1973 Yom Kippur War, the Israeli invasion of Lebanon and its aftermath, and pre- and post-strike imagery of the 1986 raid performed by American air forces on Libya. In 1987, Kadena-primarily based SR-71 crews flew a number of missions over the Persian Gulf, revealing Iranian Silkworm missile batteries that threatened industrial shipping and American escort vessels.

As the overall performance of space-primarily based surveillance systems grew, along with the effectiveness of ground-based air defense networks, the Air Force began to drop enthusiasm for the high-priced system and the 9th SRW ceased SR-71 operations in January 1990. Despite protests by military leaders, Congress revived the system in 1995. Continued wrangling over operating budgets, even so, soon led to final termination. The National Aeronautics and Space Administration retained two SR-71As and the one particular SR-71B for higher-speed analysis projects and flew these airplanes till 1999.

On March 6, 1990, the service profession of a single Lockheed SR-71A Blackbird ended with a record-setting flight. This particular airplane bore Air Force serial quantity 64-17972. Lt. Col. Ed Yeilding and his RSO, Lieutenant Colonel Joseph Vida, flew this aircraft from Los Angeles to Washington D.C. in 1 hour, 4 minutes, and 20 seconds, averaging a speed of 3,418 kph (two,124 mph). At the conclusion of the flight, ‘972 landed at Dulles International Airport and taxied into the custody of the Smithsonian’s National Air and Space Museum. At that time, Lt. Col. Vida had logged 1,392.7 hours of flight time in Blackbirds, much more than that of any other crewman.

This certain SR-71 was also flown by Tom Alison, a former National Air and Space Museum’s Chief of Collections Management. Flying with Detachment 1 at Kadena Air Force Base, Okinawa, Alison logged a lot more than a dozen ‘972 operational sorties. The aircraft spent twenty-four years in active Air Force service and accrued a total of two,801.1 hours of flight time.

Wingspan: 55’7"

Length: 107’5"

Height: 18’6"

Weight: 170,000 Lbs

Reference and Additional Reading:

Crickmore, Paul F. Lockheed SR-71: The Secret Missions Exposed. Oxford: Osprey Publishing, 1996.

Francillon, Rene J. Lockheed Aircraft Considering that 1913. Annapolis, Md.: Naval Institute Press, 1987.

Johnson, Clarence L. Kelly: More Than My Share of It All. Washington D.C.: Smithsonian Institution Press, 1985.

Miller, Jay. Lockheed Martin’s Skunk Operates. Leicester, U.K.: Midland Counties Publishing Ltd., 1995.

Lockheed SR-71 Blackbird curatorial file, Aeronautics Division, National Air and Space Museum.

DAD, 11-11-01