Some cool aluminium China machining china images:

Falcon 9 Booster

Image by jurvetson

The Falcon 9 booster tank is made of aluminum lithium alloy. Welding it without forming hydrogen bubbles is tricky. SpaceX uses friction stir welding throughout.

I had to crop the welding jig from the photo because of ITAR restrictions. Let me just say that it is very clever, and the challenges are like building a ship in a bottle.

I have also collected some interesting details on the Falcon 1 flights so far:

Flight 1: The booster engine cutoff early, and the rocket went only one mile up. The video of what happened next has not been seen outside SpaceX. Without stage separation, the whole rocket tumbled back to crash 300 ft. from the launch pad, causing a gigantic fireball. There are no people on the atoll during launches, but there were plenty of cameras catching the action, and the smoke that enveloped the entire launch area. The remains of the rocket were collected from the reef at low tide.

Flight 2: Programming mistake in the upper stage led to improper feedback control loops and it wobbled out of control.

Flight 3: While the lack of stage separation has been discussed, it is a bit more interesting. The upper stage ignited inside of the interstage coupler… and that destroyed the fragile upper stage bell (which is as thin as a Coke can).

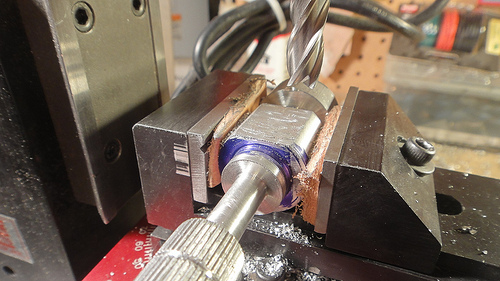

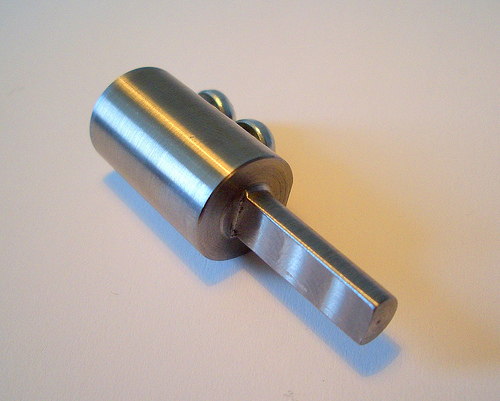

Flight 4: Perfect flight, but ironically, the first without a real payload. The Malaysians sat this one out, and will fly their satellite in Flight 5. The dummy payload in this flight was machined aluminum with a realistic mass profile and was named the RATsat after the initials of the employees who cranked it out over a weekend.

After entering orbit, they restarted the sustainer motor, a capability test that was not pre-announced.

[Update: This post and text were before I had any involvement with SpaceX. And the subsequent Flight 5 was a total success, with accurate satellite deployment]

Flight 4 is memorialized in the Space X Music Video.

I gotta fly now… on a day trip to China…

Steven F. Udvar-Hazy Center: P-40 Warhawk, SR-71 Blackbird, Naval Aircraft Factory N3N seaplane, Space Shuttle Enterprise

Image by Chris Devers

Quoting Smithsonian National Air and Space Museum | Curtiss P-40E Warhawk (Kittyhawk IA):

Whether known as the Warhawk, Tomahawk, or Kittyhawk, the Curtiss P-40 proved to be a successful, versatile fighter during the first half of World War II. The shark-mouthed Tomahawks that Gen. Claire Chennault’s "Flying Tigers" flew in China against the Japanese remain among the most popular airplanes of the war. P-40E pilot Lt. Boyd D. Wagner became the first American ace of World War II when he shot down six Japanese aircraft in the Philippines in mid-December 1941.

Curtiss-Wright built this airplane as Model 87-A3 and delivered it to Canada as a Kittyhawk I in 1941. It served until 1946 in No. 111 Squadron, Royal Canadian Air Force. U.S. Air Force personnel at Andrews Air Force Base restored it in 1975 to represent an aircraft of the 75th Fighter Squadron, 23rd Fighter Group, 14th Air Force.

Donated by the Exchange Club in Memory of Kellis Forbes.

Manufacturer:

Curtiss Aircraft Company

Date:

1939

Country of Origin:

United States of America

Dimensions:

Overall: 330 x 970cm, 2686kg, 1140cm (10ft 9 15/16in. x 31ft 9 7/8in., 5921.6lb., 37ft 4 13/16in.)

Materials:

All-metal, semi-monocoque

Physical Description:

Single engine, single seat, fighter aircraft.

• • • • •

See more photos of this, and the Wikipedia article.

Details, quoting from Smithsonian National Air and Space Museum | Lockheed SR-71 Blackbird:

No reconnaissance aircraft in history has operated globally in more hostile airspace or with such complete impunity than the SR-71, the world’s fastest jet-propelled aircraft. The Blackbird’s performance and operational achievements placed it at the pinnacle of aviation technology developments during the Cold War.

This Blackbird accrued about 2,800 hours of flight time during 24 years of active service with the U.S. Air Force. On its last flight, March 6, 1990, Lt. Col. Ed Yielding and Lt. Col. Joseph Vida set a speed record by flying from Los Angeles to Washington, D.C., in 1 hour, 4 minutes, and 20 seconds, averaging 3,418 kilometers (2,124 miles) per hour. At the flight’s conclusion, they landed at Washington-Dulles International Airport and turned the airplane over to the Smithsonian.

Transferred from the United States Air Force.

Manufacturer:

Lockheed Aircraft Corporation

Designer:

Clarence L. "Kelly" Johnson

Date:

1964

Country of Origin:

United States of America

Dimensions:

Overall: 18ft 5 15/16in. x 55ft 7in. x 107ft 5in., 169998.5lb. (5.638m x 16.942m x 32.741m, 77110.8kg)

Other: 18ft 5 15/16in. x 107ft 5in. x 55ft 7in. (5.638m x 32.741m x 16.942m)

Materials:

Titanium

Physical Description:

Twin-engine, two-seat, supersonic strategic reconnaissance aircraft; airframe constructed largley of titanium and its alloys; vertical tail fins are constructed of a composite (laminated plastic-type material) to reduce radar cross-section; Pratt and Whitney J58 (JT11D-20B) turbojet engines feature large inlet shock cones.

• • • • •

Quoting Smithsonian National Air and Space Museum | Naval Aircraft Factory N3N:

In 1934 the Naval Aircraft Factory in Philadelphia was tasked to manufacture a new primary trainer for the U.S. Navy. Following successful tests, this little biplane trainer was built in both land and seaplane versions. The Navy initially ordered 179 N3N-1 models, and the factory began producing more than 800 N3N-3 models in 1938. U.S. Navy primary flight training schools used N3Ns extensively throughout World War II. A few of the seaplane version were retained for primary training at the U.S. Naval Academy. In 1961 they became the last biplanes retired from U.S. military service.

This N3N-3 was transferred from Cherry Point to Annapolis in 1946, where it served as a seaplane trainer. It was restored and displayed at the Naval Academy Museum before being transferred here.

Transferred from the United States Navy

Manufacturer:

Naval Aircraft Factory

Date:

1941

Country of Origin:

United States of America

Dimensions:

Overall: 10ft 9 15/16in. x 25ft 7 1/16in. x 34ft 1 7/16in., 2090lb. (330 x 780 x 1040cm, 948kg)

Materials:

bolted steel-tube fuselage construction with removable side panels wings, also constructed internally of all metal, covered with fabric like the fuselage and tail.

Physical Description:

Bright yellow bi-plane, hand crank start. Cockpit instrumentation consists of an altimeter, tachometer, airspeed indicator, compass, turn and bank indicator, and a combination fuel and oil temperature and pressure gauge, floats.

• • • • •

See more photos of this, and the Wikipedia article.

Details, quoting from Smithsonian National Air and Space Museum | Space Shuttle Enterprise:

Manufacturer:

Rockwell International Corporation

Country of Origin:

United States of America

Dimensions:

Overall: 57 ft. tall x 122 ft. long x 78 ft. wing span, 150,000 lb.

(1737.36 x 3718.57 x 2377.44cm, 68039.6kg)

Materials:

Aluminum airframe and body with some fiberglass features; payload bay doors are graphite epoxy composite; thermal tiles are simulated (polyurethane foam) except for test samples of actual tiles and thermal blankets.

The first Space Shuttle orbiter, "Enterprise," is a full-scale test vehicle used for flights in the atmosphere and tests on the ground; it is not equipped for spaceflight. Although the airframe and flight control elements are like those of the Shuttles flown in space, this vehicle has no propulsion system and only simulated thermal tiles because these features were not needed for atmospheric and ground tests. "Enterprise" was rolled out at Rockwell International’s assembly facility in Palmdale, California, in 1976. In 1977, it entered service for a nine-month-long approach-and-landing test flight program. Thereafter it was used for vibration tests and fit checks at NASA centers, and it also appeared in the 1983 Paris Air Show and the 1984 World’s Fair in New Orleans. In 1985, NASA transferred "Enterprise" to the Smithsonian Institution’s National Air and Space Museum.

Transferred from National Aeronautics and Space Administration