Morgantown, PA (PRWEB) January 07, 2015

Behringer, a globe-class provider of bandsawing machines, circular cold saws and structural fabricating equipment, has added a lot more normal functions to its HBE Dynamic Series horizontal bandsaws with out growing selling price. Currently economically priced for spending budget-intelligent organizations, HBE saws now consist of automatic precision servo down feed handle, blade protection sensor technologies and other regular attributes made to boost cutting rates and throughput, and to lessen downtime.

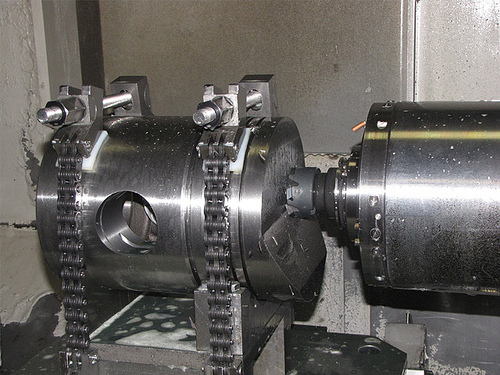

Owing to improvements in manufacturing techniques and advanced element design, Behringer engineers effectively re-engineered the HBE series of saws producing a couple of of the much more common options common functions – at no added price. “One of the most well-known choices is the servo-driven automatic precision down feed handle,” mentioned Joe Suydam, Behringer sales and marketing and advertising associate. A sensor-driven cutting stress control is located at the back of the saw blade. Suydam explained that positioning the sensor directly at the saw blade assures that pressure adjustments are quickly and precise. The handle automatically adjusts blade pressure to create the optimum balance in between feed rate and blade stress. “This final results in optimum cutting speed with a maximum chip load, and at the very same time prolongs blade life,” stated Suydam.

One more common selection now included as standard on HBE Series saws is automatic feed handle (AFC). The Behringer AFC feature automatically adjusts cutting parameters such as blade speed and downfeed rate to the material grade and shape. This permits operators to create flexible material feed applications leveraging cutting information based on particular material grade. Furthermore, a fault/alert history might be viewed at any time by the operator. The detailed information displayed in plain text is useful for both planning and analysis of previous projects.

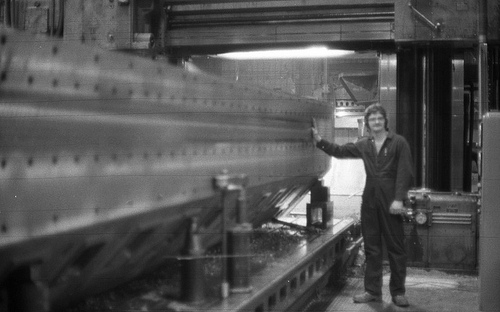

Designed for efficiency in higher production metal cutting operations, HBE Dynamic Series horizontal bandsaws are developed to meet a broad range of applications in the steel trade, mechanical engineering, tool creating and metalworking shops. The saws utilize a higher torque, frequency-controlled blade drive motor. Specialized gearing in the drive final results in low energy consumption but produces the blade power and speed needed for quickly cutting and peak throughput prices.

As with all Behringer bandsaws, the cast iron dual column construction of the HBE saw frame offers the rigidity needed to get rid of anxiety, decrease vibrations and boost torsion resistance in the course of cutting. Two linear approaches and 4 ball slides facilitate precise and precise vertical movement of the blade. Cutting accuracy is further enhanced by the horizontal band arrangement and hydraulically tensioned, double-sided linear guide bearings for the band wheels.

The HBE Dynamic saw is offered in four models – 261A, 321A, 411A and 511A. The HBE-261A does not contain the common attributes upgrade. HBE cutting variety is from ten.two” to 20.” diameter for round stock and from 11.eight” x ten.two” up to 20.” x 20.” for flat stock. Stroke length is 25.six” with exceptional tolerances controlled by an electrically powered ball screw driven material feed gripper. Blade speed ranges from 50-350 ft/min.

For far more information on the Behringer HBE Dynamic Series higher-efficiency bandsaws, get in touch with Behringer Saws, Inc., 721 Hemlock Road, Morgantown, PA 19543. Contact toll-totally free at 888-234-7464.

###

About Behringer Saws

Behringer Saws, Inc. provides a full range of sawing and turnkey pre- and post-reduce material handling productivity-enhancing items. Behringer supplies planet-class top quality automatic bandsaws to corporations, service centers, job shops and companies all through the globe. The firm also delivers the Behringer Eisele brand of manual, semi-automatic and automatic miter circular cold saws, high performance circular cold saws utilizing bi-metal or carbide saw blades and CNC miter circular sawing systems. Also, the Vernet Behringer line of structural fabricating gear involves high functionality drilling, punching, shearing, notching and marking machines along with beam coping and drilling and sawing lines.