Charlotte, NC (PRWEB) August 28, 2014

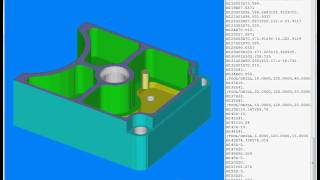

At IMTS 2014 Okuma will introduce its new LU4000 EX CNC lathe which utilizes two turrets, enabling two tools to work simultaneously, delivering approach flexibility as nicely as higher removal prices. This machine is outstanding for machining parts for the automotive business. At IMTS this machine will be shown cutting a camshaft utilizing Machining Navi for chatter reduction and tooling from Sandvik, a member of Partners in THINC.

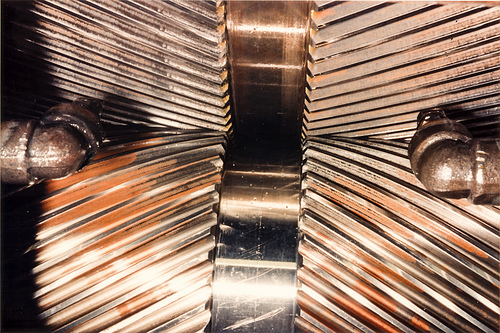

The LU4000 EX incorporates a new 45° “box bed” with all box way construction, three point bearing assistance for the spindle, crown gear turret coupling for each turrets, two energy ranges and the Okuma THINC®-OSP control, offering a foundation for a long production life. This CNC lathe is Okuma’s most recent evolution of 4-axis turning in the ten-15” chuck class.

Important Functions of the LU4000 EX CNC Lathe

Max Turning Diameter: mm (in) Ø430 (Ø16.93) (upper turret)

Ø280 (Ø11.02) (decrease turret)

Spindle Nose Variety: A2-8

Main Spindle Speed Range: min⁻¹ 40~4,200

Milling Spindle Speed Range: min⁻¹ 45~6,000

X/Z Axis Travel: mm (in) 300 (11.81) / 740 (29.13) (upper turret)

195 (7.68) / 700 (27.56) (reduce turret)

Y Axis Travel: mm (in) 140[+/-70] (five.51[+/-two.76])

For far more info on Okuma’s LU4000 EX check out http://www.okuma.com/lu4000-ex and Okuma America Corporation booth S-8500 at IMTS 2014.

About Okuma America Corporation

Okuma America Corporation is the U.S.-primarily based sales and service affiliate of Okuma Corporation, a globe leader in CNC (personal computer numeric manage) machine tools, founded in 1898 in Nagoya, Japan. The business is the industry’s only single-source provider, with the CNC machine, drive, motors, encoders, spindle and CNC manage all manufactured by Okuma. Okuma’s innovative and reputable technology, paired with complete, localized service protection, permits customers to run continuously with self-assurance – maximizing profitability. Along with its sector-top distribution network (largest in the Americas), and Partners in THINC, Okuma facilitates top quality, productivity and efficiency, empowering the customer and enabling competitive advantage in today’s demanding manufacturing environment. For far more data, go to http://www.okuma.com or adhere to us on Facebook or Twitter @OkumaAmerica.

About Partners in THINC

Partners in THINC is a collaboration network of far more than 40 market leaders who come with each other to resolve difficulties and explore new productivity suggestions for genuine-globe producers. With the open architecture, Pc-based THINC®-OSP manage as its nucleus, Partners in THINC brings specialized equipment, experience and a commitment to give the best feasible integrated options to the finish-user. For a lot more data, visit http://www.okuma.com/partners-in-thinc.

###

Connected Machined Turned Components Press Releases