Zhengzhou, China (PRWEB) December 11, 2014

Wire brushes are some of the most widespread industrial finishing tools on the market and can be utilized for a quantity of applications. iAbrasive.com distributes wire brushes into fantastic varieties primarily based on different shapes and application, such as wire wheels, cup brushes, finish brushes, bevel brushes, tube brushes, honing brushes, scratch brushes, bristle brushes, and much more. iAbrasive.com has all sorts of wire brushes for users’ application.

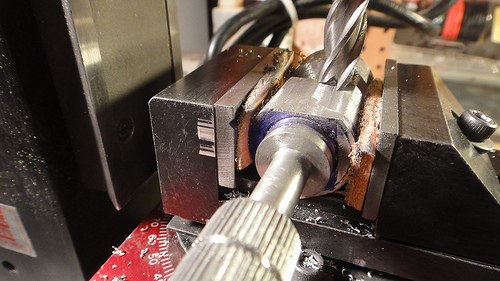

Wheel brushes are perfect for deburring machined castings, turbine blades, cam shafts, machined components, edges on saw-cut extrusions, powdered metal components and gears, portion finishing and sharpening for cutting tool inserts, edge radiusing on components, surface finishing on steel, stainless steel, aluminum, brass and other materials, light cleaning and polishing for ferrous and non-ferrous components.

Disc brushes are employed for deburring fine-blanked parts, edge radiusing on fine-blanked parts, polishing machined parts and surfaces, deburring cast engine blocks, airframe elements, wheel rims, tubing and aluminum extrusions, blending tool marks and finishing flat machined surfaces, generating specific edge radii on tooth profiles of machined gears, surface preparation and finishing on metal and wood, deburring and finishing cast aluminum wheel rims, deburring and edge radiusing aluminum engine heads, removing burrs and sharp edges on machined flat surfaces of cast aluminum engine intake manifolds, surface finishing and burr removal on hydraulic elements, rust and scale removal, scrubbing and cleaning steel and aluminum sheets, clean pre-cast concrete molds, finishing surfaces prior to painting, plating or powder coating, sanding and texturing wood surfaces.

Bristle brushes are flexible and conform to irregular surfaces. You can anticipate a consistent finish even on the most complex components. Because they contain no wire filaments, they help consumers meet increasingly hard safety requirements.

Main wire sorts of wire brushes incorporate straight wire, crimped wire, and twist-knotted wire. Crimped wire brushes are best suited for appearance finishing, edge blending, cleaning and polishing of internal and external tube diameter surfaces as well as irregular external surfaces. Crimping of wire bristles in wire brushes is accomplished for two significant causes:

1. Crimping tends to make the wires stand apart from every single other

two. Crimping absorbs the flexing and vibrations and also assists to avoid wire fatigue and breakage

Twist-Knotted Wire Brushes

When heavy brushing action is required, knotted wire brushes are a excellent alternative. These wire brushes possess durable cutting action for cleaning applications. Simply because of their knotted bristles or tufts, these wire brushes are far more rugged creating the cutting action much more aggressive. The tufts will also absorb the vibration which aids eliminate the bending and, as a result, decrease wire fatigue. In addition, with the prime third of the knotted bristles being slightly flared, the style of knotted wire brushes is the explanation why they are able to sustain an aggressive cutting action. One particular of the most widespread applications for knotted wire brushes these days is in oil fields exactly where heavy brushing action is necessary.

Twisted brushes are used for deburring cross-hole intersections in machined valve bodies and manifolds, deburring camshaft bores and crankcase bores, debris removal and cleaning internal bores on cast engine blocks, finishing and polishing small inside diameter holes on machined components, deburring and cleaning inner walls of tubing and pipes.

Author: Liwei Chu

Copyright: iAbrasive.com–Abrasives & Diamond Tools Industry