A few nice milling and machining images I discovered:

Image from web page 96 of “Descriptive pamphlet of the Richmond Mill Furnishing Functions: all sizes of mill stones and comprehensive grinding and bolting combined husk or portable flouring mills, portable corn and feed mills smut and separating machines zigzag and

Image by Web Archive Book Photos

Identifier: descriptivepamph00rich

Title: Descriptive pamphlet of the Richmond Mill Furnishing Performs: all sizes of mill stones and comprehensive grinding and bolting combined husk or portable flouring mills, transportable corn and feed mills smut and separating machines zigzag and oat separators, dustless separators, warehouse separators, water wheels mill shafting pulleys spur and bevel, iron and core, gearing ..

Year: 1873 (1870s)

Authors: Richmond Mill Furnishing Functions. [from old catalog]

Subjects: Nordyke, Marmon & Business Flour market Milling machinery Mills and mill-function

Publisher: Richmond, Ind., Telegram Steam Print. Co.

View Book Web page: Book Viewer

About This Book: Catalog Entry

View All Pictures: All Images From Book

Click right here to view book on the web to see this illustration in context in a browseable on the web version of this book.

Text Appearing Prior to Image:

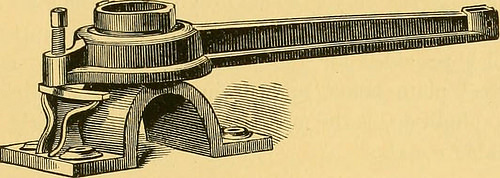

These engravings illustrate the style of hand wheel and screw withcap and washer that we make and furnish with our combinedhusk mills, and when ordered we send them with the irons neededwith mill stones. The figure on the proper shows the hand wheel,screw cap and washer in position when prepared for operation. Thewrought iron screw is cut in a lathe and is what is termed a squarethread. The wheel cap and washer are all turned and polished, mak-ing a very good searching, tough fixture, as well as an correct implies ofadjusting the stone. We occasionally make these of brass. RICHMOND MILL FURNISHING Works. 85 Lighter Levers and Arched Step.

Text Appearing Right after Image:

This shows our pattern for arched bridge pot and lighter lever forgeared mills or when an elevated step is wanted. The partholding the steel on which spindle rests, is contained in a centrallifting chamber, which is turned to match the physique of the arch, like apiston, as a result enabling a ideal perpendicular movement without anyliability to vary from its true position the heavy set-screw at the rearend of the lever is to admit of a lot more adjustment the lever can bemoved around at most any needed angle with out interfering withany component of the step. We provide signifies (not shown in this reduce) totram the spindle by screws placed in the central lift element of the step,when desired. Mill Actions.

Note About Pictures

Please note that these photos are extracted from scanned page images that might have been digitally enhanced for readability – coloration and look of these illustrations might not perfectly resemble the original function.

Image from web page 23 of “Descriptive pamphlet of the Richmond Mill Furnishing Works: all sizes of mill stones and full grinding and bolting combined husk or portable flouring mills, transportable corn and feed mills smut and separating machines zigzag and

Image by World wide web Archive Book Photos

Identifier: descriptivepamph00rich

Title: Descriptive pamphlet of the Richmond Mill Furnishing Works: all sizes of mill stones and full grinding and bolting combined husk or portable flouring mills, portable corn and feed mills smut and separating machines zigzag and oat separators, dustless separators, warehouse separators, water wheels mill shafting pulleys spur and bevel, iron and core, gearing ..

Year: 1873 (1870s)

Authors: Richmond Mill Furnishing Operates. [from old catalog]

Subjects: Nordyke, Marmon & Organization Flour industry Milling machinery Mills and mill-work

Publisher: Richmond, Ind., Telegram Steam Print. Co.

View Book Web page: Book Viewer

About This Book: Catalog Entry

View All Pictures: All Images From Book

Click here to view book on the web to see this illustration in context in a browseable online version of this book.

Text Appearing Prior to Image:

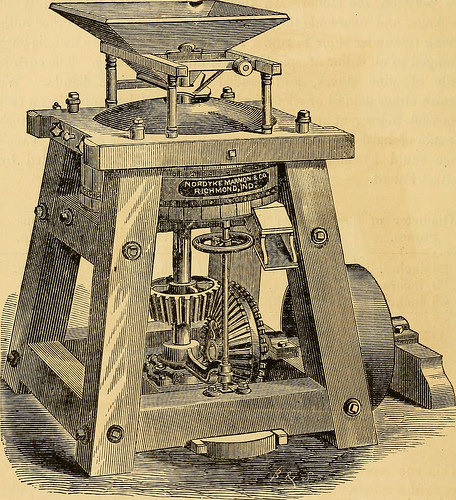

s about bolts, are supplied above the bedstone-frame, holding it down whilst grinding, for the critical dutyof enabling said bed-stone to yield up in case any challenging substance en-ters between the stones. In this way we stop the liability ofbreakage, and overcome the quite common objection to all other millshaving the beneath stone to run. In addition we give a metalic busharranged to oil collar of spindle even though mill is operating. The curb ismade of pine staves, and banded with neat iron bands. Wefurnish either damsel or silent feed as desired. The runner has a castiron back to stop any inclination to put on out of balance. The huskis created of challenging wood and extremely strong. Numerous other points of excel-lence could be mentioned. The improvements are protected byLetters-Patent. Diameter ofStones. Diameter ofPulley. Width of beltto drive. Revolutionsper minute. 26 inches.30 inches.36 inches. 18 inch.20 inch.24 inch. 7 inch. eight inch.10 inch. 440400330 16 DESCRIPTIVE PAMPHLET OF THE GEARED MILLS.

Text Appearing After Image:

OUR Below RUNNER GEARED MILLS Are substantially the exact same as set forth on page 14, excepting they areprovided with heavy gearing, horizontal shaft, pulley and boxing linedwith anti-friction metal. The gear is faced ofi in a lathe ahead of thecogs are place in, the pulley is turned and balanced, all becoming fitted up inthe very best manner fIom new patterns, robust and in good proportion.We have the greatest and smoothest operating geared mill in the marketplace. RICHMOND MILL FURNISHING Works. 17 UPPER RUNNER PULLEY MILLS.

Note About Photos

Please note that these photos are extracted from scanned page pictures that may have been digitally enhanced for readability – coloration and appearance of these illustrations could not perfectly resemble the original function.

Image from page 9 of “Descriptive pamphlet of the Richmond Mill Furnishing Works: all sizes of mill stones and complete grinding and bolting combined husk or transportable flouring mills, transportable corn and feed mills smut and separating machines zigzag and o

Image by Web Archive Book Images

Identifier: descriptivepamph00rich

Title: Descriptive pamphlet of the Richmond Mill Furnishing Performs: all sizes of mill stones and full grinding and bolting combined husk or portable flouring mills, transportable corn and feed mills smut and separating machines zigzag and oat separators, dustless separators, warehouse separators, water wheels mill shafting pulleys spur and bevel, iron and core, gearing ..

Year: 1873 (1870s)

Authors: Richmond Mill Furnishing Performs. [from old catalog]

Subjects: Nordyke, Marmon & Company Flour market Milling machinery Mills and mill-perform

Publisher: Richmond, Ind., Telegram Steam Print. Co.

View Book Page: Book Viewer

About This Book: Catalog Entry

View All Images: All Photos From Book

Click right here to view book on the web to see this illustration in context in a browseable on the internet version of this book.

Text Appearing Prior to Image:

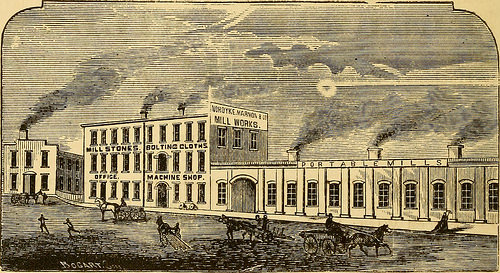

RICHMOND, IND. TELEGRAM STEAM PRINTING Business. . 1872. ^HtN GTO^

Text Appearing Right after Image:

COPYRIGHT SECURED. Entered according to act of (,V)ngress, in the year 1872, by Nordyke, Marmon &Co.) in the Workplace of the Librarian of Congress, at Washington. CONTENTS. Introductory five Mill Stones 8 Constructing and Balancing Stones 9 Standing and Operating Balance 9 Bolting Cloth 13 Below-Runner Mills 14 Under-Runner Geared Mills 16 Upper-Runner Mills 17 Pulley Mills 18 Attaching and Driving 18 Geared Mills 19 Single Reel Bolt, total, 21 Portable Mill and Bolt 22 Comprehensive Portable Grinding and Belting Flour Mills 24 Combined Mill Husk 31 Double Reel Bolts 35 Grinding and Flouring, and Capacity 35 Keeping in Order 37 Directions for Ordering 39 Setting up and Starting 40 Smut and Separating Machines 41 Ordering Smut and Separating Machines 44 Dustless Oat Separator and Zigzag 45 Flour Packers 47 Bran Dusters 49 Farm and Plantation Mills 52 Corn and Cob Crusher, and Grinder 54 Corn Shellers 55 Hominy Mills 58 Scales 60 Weight of different Items 64 Contents of a Hopper, how to uncover. 6descriptivepamph00rich

Note About Pictures

Please note that these photos are extracted from scanned web page pictures that may possibly have been digitally enhanced for readability – coloration and look of these illustrations might not perfectly resemble the original work.