Since1975, our company has been specializing in China manufacturing forged and CNC mechanical metal parts. We currently supplies to numerous markets including: Light and Electronic metal parts, Automobile industry, loudspeaker metal parts, motors parts and many additional related industries. We have been providing our products to our customers worldwide, including North American, Europe, Southeast Asia , etc.

Parts are Cold-forged and Head-Formed on our forging presses ranging from 110 to 1000 tons capacity. We operate our own sawing facility and affiliated machine and die shop for all our tooling requirements. We offers 100% on time delivery and –0- PPM rejection rates and will develop a plan for specifically providing your company with on time deliveries.

We do our best to satisfy our customers not only in the quality of our products, but also in our service. So far, we set factories in Taiwan and Malaysia to promote technology for customers’ products more precision. We will continue our efforts because customers’ complete satisfaction is our priority.

Welcome to visit our web page for further information. Thanks,

Produce Capabilities :

Automotive components & motors parts including steering mechanism parts, drive shaft parts, transmission parts, brake system parts, knuckles, shock absorber parts, connecting rods, bottom brackets, suspension system parts.

Motorcycle parts, including handle bases, triangular upper mounts, starter bars, drive gears, transmission parts.

General industrial applications forging, cold forging, cold forming and turning parts

Multi-forming process products, and heading parts with precision machining

Cold Forged – autmotive components & motors parts

Various thread forming and tapping machining

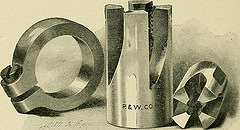

Cutting Example of Cold Forged Parts

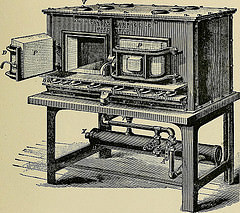

Precision NC Auto China Lathe Work

Shafts & special-headed parts

Headed rivet, axle and pins

Screw machined products China

Engineering components

Special bolt and loctite

Custom fasteners

Tubular parts

Advantages of forging, cold forging and cold forming :

High precision and accurate shape

Excellent surface quality

Improved mechanical characteristics

Considerable reduction of material

Limited machining time

Production Range :

Up to 150mm Outside diameters

Up to 100mm in length

Specialize in extruded shafts

Thread rolling range: Up to 50mm Outside diameters

Please to search MILLION INTERWORK SDN. BHD. by Yahoo, Google or any search engines for the details..

forging,forged,CNC,forge,tube,seamless pipe,spacer,rivet,washer,Screws,Bolt,axle,thumb,pin,forming,thread,tapping,speaker,yoke,flange,Shafts,bits,sleeves,loctite,spacer,t-yoke,pot,bush,Fastener,boss,rod,