Los Angeles, CA (PRWEB) July 09, 2013

Brush Investigation Manufacturing (BRM), maker of versatile hones and a full line of industrial brushes, is announcing a new video featuring its versatile and dependable Flex-Hone® tool. BRM’s In-Machine Setup: Automated Deburring and Finishing video shows makers how to automate burr removal, edge blending, and surface finishing with flexible honing tools. By utilizing cylinder hones after machining, manufacturers can speed secondary operations and permit gear to run at optimum cycle occasions.

Burr Removal, Edge Blending, and Plateau Finishing

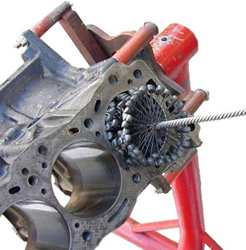

Cutting, turning, and drilling metal parts creates raised areas known as burrs that can impact dimensional tolerances, result in element misalignments, and limit the overall efficiency of machined elements. With cross-drilled holes, burrs can also impede the flow of cooling fluids, lubricants, and gases. Deburring is essential, of course, but manufacturers also want to impart a surface finish that increases bearing location, reduces friction and wear, and promotes lubrication.

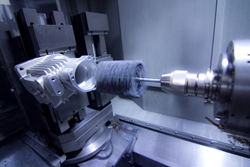

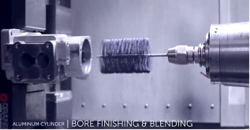

As BRM’s new video shows, the Flex-Hone® tool solves these and other surface finishing challenges. Examples include cross-drilled holes in 7075 aluminum cylinders and radial slots in 6061 aluminum bores. Just 3 minutes and 32 seconds long, the new BRM video also shows how the Flex-Hone® reduces surface roughness and improves surface finish down to the single RA level. Close-ups of the crosshatch pattern that versatile honing imparts reveal a substantially flat or plateau finish on cylinder walls.

Deciding on and Using Flexible Honing Tools

BRM’s flexible hones are accessible in ten distinct abrasive sorts from 20 to 800 grit, and come in diameters ranging from four-mm to 36”. To automate secondary operations, companies can use the Flex-Hone® tool in a machining center to remove burrs uniformly, effectively, and expense-successfully while enhancing surface finish at the identical time. With CNC equipment, use a Jacobs style chuck directly on the brush tool’s stem wire. BRM plateau hones also mount in lathes, mills, drill presses, and electric hand drills to replace labor-intensive and time-consuming manual deburring operations.

Self-centering, self-aligning, and self-compensating for put on, the Flex-Hone® tool follows bore geometry and will not affect size, ovality, or concentricity. Versatile hones are mostly surface finishing and deburring tools, and are not created for heavy-duty or high-precision metal removal. As the In-Machine Setup: Automated Deburring and Finishing video explains, always use versatile hones with a honing oil or coolant for lubrication.

About Brush Study Manufacturing

Brush Investigation Manufacturing (BRM), makers of a complete line of flexible honing tools and industrial brushes, is positioned in Los Angeles, California. Because 1958, BRM has been solving difficult finishing troubles with brushing technology. Download the Flex-Hone® Resource Guide for a lot more data about how to pick and use flexible honing tools.

Media Contact:

Heather Jones

Director of Advertising

Brush Research Manufacturing Co. Inc.

4642 Floral Drive

Los Angeles, CA 90022

HJones(at)brushresearch(dot)com

For Instant Release:

http://www.brushresearch.com/

Ph: (323) 261-2193