A few nice precision engineering companies images I found:

Band of Brothers: The La Fiere Bridge over the Merderet River

Image by Dog Company

This isn’t an Easy Company 506th site, but this set is dedicated to all of the paratroopers, and I think you’ll be interested in this.

In this picture, I’m standing on the La Fiere Bridge over the Merderet River, about 1-2 km west of Ste Mere Eglise. On D-Day, this field was flooded. The Germans had jammed the lock on a dam to flood a lot of fields that were potential airborne landing site.

One thing I learned about the consequence is visible in this picture. If you were a paratrooper and you landed in that field, you were in about three feet of water. If you landed in the river, you were in over your head. I read the account of one trooper who landed in the river and had to use his Mae West life preserver to surface. Then as he gasped for air, he had to cut himself out of his harness with his knife, then was able to drag himself to safety. Another account I read was about a trooper who landed in this field, and wind gusts blew him, face down (so he was drowning) across the field until he was able to turn over and get out of his chute.

The Germans were massed to the left of the river, and a small contingent of men from the 82nd Airborne and the 505th of the 101st formed a defense on the right side. They were there for one job: prevent the Germans from counterattacking with armor across the Merderet and hitting the paratroops from their left flank (Ste Mere Eglise would have been totally exposed if they didn’t hold this bridge. At first, they had rifles, carbines and a light mortar, and then they got more equipment. Here are some downloads I clipped from the internet to illustrate

La Fiere Bridge: D-Day June 6, 1944

Around 1:00 a.m. on June 6, 1944, Marcus Heim jumped out of a C-47 transport plane over Normandy, France. Heim was part of A Company, 505, their specific objective was to seize and hold the La Fiere Bridge over the Merderet River until reinforcements from the amphibious portion of the Allied invasion arrived.

"In all of the airborne operations of the ETO, the Merderet Bridgehead was the one attended by the greatest difficulty and hardships of the individual assemblies … these conditions so frequently brought forth the finest characteristics of the American soldier." – S L A Marshall

Enclosed are Marcus Heim’s recollections of June 6. That day, their small four-man team set up a roadblock next to the La Fiere Bridge and was responsible for repelling several powerful German counter attacks.

I landed about twenty-five feet from a road and before I could get my rifle assembled, I heard a motorcycle approaching. I remained still as I did not have time to assemble my rifle, and watched two German soldiers pass by. After they passed and I had my rifle together I found other paratroopers and our equipment bundle and set off for the bridge over the Merderet River. We were to hold the bridge until the soldiers who landed on the beach arrived later that day, but it was three days before they reached our position.

As you stand at the La Fiere Bridge looking in the direction of Ste Mere- Eglise, the Manor House is on the right and was the living quarters. There were several buildings, one a large barn, which was close to the Merderet River. The Germans had occupied the Manor House and were driven out by "A" Company, 505, after heavy fighting. As you pass the Manor House toward Ste Mere-Eglise, the road goes up hill and curves to the left. Across from the Manor House there was a pathway which was about four feet wide and now is a causeway was narrow and had brush and trees on each side, some hung over the causeway. The fields were completely flooded right up to the causeway. The town on Cauquigny was about 800 to 900 yards from the bridge, and it was in German hands. The causeway curved to the right about 60 or 65 yards from the bridge.

Map of The La Fiere Bridge Head. Heim’s position is near the bottomof the map (U.S. Army).

When we arrived at the bridge, men were placed down the pathway to the right and to the left of the Manor House and out buildings. The four bazooka men included: Lenold Peterson, and myself, John Bolderson and Gordon Pryne. Peterson and I took up positions on the Manor House side facing Cauquigny, below the driveway. There was a concrete telephone pole just in front of us and we dug in behind it. We knew that when the Germans started the attack with their tanks, we would have to get out of our foxhole and reveal our position to get a better view of the tanks. Bolderson and Pryne were on the right side of the road just below the pathway. I do not remember how many paratroopers were around us, all I saw was a machine gun set up in the Manor House yard. On the right side down the pathway a few riflemen took up positions.

There was a 57-millimeter cannon up the road in back of us along with another machine gun. We carried antitank mines and bazooka rockets from the landing area. These mines were placed across the causeway about 50 or 60 feet on the other side of the bridge. There was a broken down German truck by the Manor House, which we pushed and dragged across the bridge and placed it across the causeway. All that afternoon the Germans kept shelling our position, and the rumor was that the Germans were going to counter attack. Around 5:00 in the afternoon the Germans started the attack. Two tanks with infantry on each side and in the rear following them was a third tank with more infantry following it. As the lead tank started around the curve in the road the tank commander stood up in the turret to take a look and from our left the machine gun let loose a burst and killed the commander. At the same time the bazookas, 57 millimeter and everything else we had were firing at the Germans and they in turn were shooting at us with cannons, mortars, machine guns and rifle fire. Lenold Peterson and I (the loader), in the forward position got out of the foxhole and stood behind the telephone pole so we could get a better shot at the tanks. We had to hold our fire until the last minute because some of the tree branches along the causeway were blocking our view. The first tank was hit and started to turn sideways and at the same time was swinging the turret around and firing at us. We had just moved forward around the cement telephone pole when a German shell hit it and we hat to jump out of the way to avoid being hit as it was falling. I was hoping that Bolderson and Pryne were also firing at the tanks for with all that was happening in front of us there was not time to look around to see what others were doing. We kept firing at the first tank until it was put out of action and on fire. The second tank came up and pushed the first tank out of the way. We moved forward toward the second tank and fired at it as fast as I could load the rockets in the bazooka. We kept firing at the second tank and we hit it in the turret where it is connected to the body, also in the track and with another hit it also went up in flames. Peterson and I were almost out of rockets, and the third tank was still moving. Peterson asked me to go back across the road and see if Bolderson had any extra rockets. I ran across the road and with all the crossfire I still find it hard to believe I made it to the other side in one piece. When I got to the other side I found one dead soldier and Bolderson and Pryne were gone. Their bazooka was lying on the ground and it was damaged by what I thought were bullet holes. Not finding Bolderson or Pryne I presumed that either one or both were injured. I found the rockets they left and then had to return across the road to where I left Peterson. The Germans were still firing at us and I was lucky again, I return without being hit. Peterson and I put the new found rockets to use on the third tank. After that one was put out of action the Germans pulled back to Cauquigy and continued shelling us for the rest of the night. They also tried two other counter attacks on our position, which also failed.

During the battles, one does not have time to look around to see how others are doing. We were told that when we took up our position by the bridge that we have to hold it at all cost until the men from the beach arrived, for if the Germans broke through they would have a good chance of going all the way to the beach. Our job was to be in the forward position by the La Fiere Bridge with our bazooka to stop any German tanks from advancing over the bridge and onto Ste Mere-Eglise and the beaches. This we accomplished all the while the Germans were continuously firing everything they had at us. After I went across the road and found more rockets for the bazooka and returned, the third tank was put out of action and the Germans retreated. When the Germans pulled back, we looked around did not see anyone, we than moved back to our foxhole. Looking back up the road toward Ste Mere-Eglise, we saw that the 57-millimeter cannon and the machine gun were destroyed. Looking down the pathway across from the Manor House we could not see any of our men. We were thinking that we were all alone and that maybe we should move from here, then someone came and told us to hold our position and he would find more men to place around us for the Germans may try again to breach our lines. We found out later, of the few that were holding the bridge at this time, most were either killed or wounded. Why we were not injured or killed only the good Lord knows.

Marcus Heim recieves the DSC from General Omar Bradley.

For holding their position and repelling the Germans on June 6, 1944, Heim, Peterson, Bolderson and Pryne were each awarded the Distinguished Service Cross.

The following letter is from John "Red Dog" Dolan, Company Commander of A Company 505 PIR, to General James Gavin. Wriiten in 1959, at the urging of Robert Murphy, the letter provides a very detailed account of A Company’s legendary actions at La Fiere Bridge. General Gavin’s transmittal letter to famed author Cornelius Ryan is also enclosed.

JOHN J. DOLAN

ATTORNEY AT LAW

BOX 1272, 141 MILK STREET

BOSTON 4, MASS.

March 15, 1959

Lt. General James N. Gavin

c/o Arthur D. Little, Inc.

30 Memorial Drive

Cambridge, Mass.

Dear General Gavin:

Thank you for your letter of March 10, 1959. It had always been my intention of answering the questionnaire of Cornelius Ryan; but realizing that it would take considerable time to give a detailed and accurate account, I kept putting it aside and then completely forgot about it until Bob Murphy spoke to me about it a few days before receipt of your letter.

I shall try to cover as much detail without making this letter too voluminous, leaving it to your judgment and discretion to delete any portion that you deem unfavorable to the outfit. You may recall that I was in command of Company "A", 505 Parachute Infantry, with the rank of First Lieutenant. The specific mission of the Company "A" was to seize and defend the bridge crossing the Merderet River on the road that ran East to West from Ste. Mere Eglise, with the purpose of preventing the movement of German troops down to the beach-head.

I don’t recall exactly what time the first Battalion jumped but it was between 1:00 and 2:00 a.m. on D-Day. We hit our drop zone right on the nose, because within twenty minutes to one-half hour, I knew our exact location. I was able to identify a "T" intersection, dirt roads 8 to 10 feet wide, near our drop zone. The upper arm of which ran generally east to west, the vertical arm running north to south, to meet the road running from Ste. Mere Eglise to our objective, the bridge at the Merderet River.

We had the usual problems of re-organization in the dark; however, about an hour before dawn, Company "A" moved out from the drop zone with about ninety (90) per cent of the men accounted for. (This was not due to luck alone, but to the cooperation of Officers, Non-Coms, and last but not least, training. Men who have to fight in the night should be trained in nighttime fighting, not just taken on a night march and digging foxholes.) We moved along this dirt road which I previously referred to as being the North-South arm of the "T" intersection, and just around here, I ran into Major McGinity. He moved out with us.

The order of march was first, Co. Headquarters, third and second platoons in that order. When we reached the road running East-West from Ste. Mere Eglise, a German motorcycle passed us going toward Ste. Mere Eglise. At this time, it was still dark, but daylight was starting to break. We crossed the road and started west toward the bridge,with a hedge row to our right between us and the road. Just about this time, contact was lost with the first platoon, so the third platoon took the lead.

About seven to eight hundred yards from the bridge, we came upon a dirt road running southeasterly from the road to the bridge. Hedgerows were on either side of this road; and beyond it in the direction of the bridge, was an open, flat field, about 100 yards deep and about 75 yards wide. It was here that I figured the Germans would defend if they intended a defense of the bridge.

I directed Lt. Donald Coxon to send his scouts out. This he did, and he also went out with them. He had plenty of personal courage but he didn’t have the heart to order them out without going with them.

A few moments later, a German machine gun opened up, killing Lt. Coxon and one of his scouts, Fergueson. Their fire was returned; and, with Major McGinity and myself leading, a few men holding and returning frontal fire, the platoon flanked to the left. At the same time, I directed Lt. Presnell to re-cross the road and attack along the northern side down to the bridge. This was done, and the second platoon didn’t meet with any fire until they arrived at the bridge.

The third platoon continued its flanking move and cut back in toward the road to the bridge. Because of the fire, we calculated that there was just one machine gun crew that was in our way. It later turned out that there must have been at least a squad dug in at this point, with at least two of them armed with machine pistols. Prisoners captured later, in addition to the German dead, amounted to about the size of one of our platoons. There were no German officers captured. I don’t know whether or not any of their enlisted men escaped.

To continue, we cut back toward the road, travelling in a Northerly direction. Major McGinity was leading and I was about three’ or four paces behind, and slightly to the right. There was a high, thick hedgerow to our left, and it was in here that I figured the machine gun was located.

When we had traveled about two-thirds of the way up the hedgerow, they opened up on us with rifle, and at least two machine pistols. I returned the fire with my Thompson Sub-Machine Gun at a point where I could see leaves in the hedgerow fluttering. Major McGinity was killed instantly. As luck would have it, there was a German foxhole to my left which I jumped into and from where I continued to fire I could only guess where to shoot, but I had to as part of the Third platoon was exposed to their fire. Lt. McLaughlin, the assistant platoon leader was wounded and died later that day. His radio operator was also killed the platoon by now was under fire from two directions, from the point where I was pinned down, and also from the direction of the bridge.

I can’t estimate how long we were pinned down in this fashion, but it was at least an hour. I made several attempts to move, but drew their fire. On my last attempt, I drew no fire. They obviously had pulled out. During all of this time, I could hear rifle and machine gunfire down by the bridge on the north side. This ceased about this time I returned to the rest of the third platoon, instructed the Non-Coms to re-organize and to maintain their present position. I then crossed the road and located the first platoon commanded by Lt. Oakley on the north side. They were moving toward the bridge, so I instructed them to continue and dig in on the right side. I went down to the bridge and found that we had received an assist from some of the 508 Prcht. Infantry about this time, I ran into Col. Eckman, and sent for my third platoon to dig in on the left or south side of the bridge. The first was already digging in on the north side.

I thought that all of the Germans had retreated; but unknown to us, there were about ten or twelve Germans holed up on the second floor of a stucco-type farmhouse. At the time they started firing. Col. Eckman and I were casually looking the situation over. It lasted about twenty minutes with about ten or twelve Germans surrendering. About a squad of men from the 508 made the actual capture.

We dug in, the disposition of my Company as follows: First platoon on the north side of the road, the third on the south and the second in reserve, about 4OO yards back, so that it could also protect the rear.

Major Kellam arrived at the bridge with Capt. Roysden, his S-3. He had most of his C.P. unit with him. I don’t know whether or not a Battalion C.P. had ever been set up as planned, at least, I don’t recall having had any communication with it. Down at the bridge now was most of Company "A", about one platoon or Company "B", a platoon of the Division Engineers (mission to blow the bridge if necessary), about half of Battalion Headquarters Company with mortars awl machine gun sections and several stray men from other regiments. The Company dug in well and quickly. I had just completed my inspection of the forward positions when we knew that an attack was coming. You will recall that in front of our position, west of the Merderet River, was a marsh at least 1000 yards wide at its narrowest point. The road running west from the bridge could better be described as a causeway.

As I recall, the mission of the 508 was to occupy a position beyond this causeway. In addition to the men who assisted us in capturing the bridge at least a company of the 508 passed through our position and moved over the causeway to their objective. They were gone at least an hour when we saw several of them retreating back across the marsh. I remember that we helped several of them out of the river, which was quite shallow.

The machine gun fire from the Germans was very heavy by now. We didn’t return their fire as there were no visible targets and our ammunition supply was limited. They attacked with three tanks, which I was unable to identify for sure; but they appeared to be similar to the German Mark IV type, or maybe a little lighter. The tanks were firing on us with machine guns and cannon.

Just about a half-hour before this attack, a 57MM A. T. gun was assigned to Company "A". I located this gun about 150 yards from the bridge on the road where it curves to the right as you approach the bridge. Incidentally, this was my C.P. and later the Battalion C.P. This gave the gun excellent cover and a good field of fire.

On the bridge I had three bazooka teams. Two of them were from Company "A" and the third was either from "B" or "C" Company. The two Company "A" bazookas were dug in to the left and right of the bridge. Because of the fact that the road itself was the causeway type, they were as of necessity dug in below the level of the road, so that in order to fire, they had to get out of their foxholes. The third bazooka was over more to the south where better cover was available.

To continue, I had just completed my inspection of our defenses and was 40 to 50 yards from the bridge. Major Kellam and Captain Royaden were nearby. The first two tanks were within 15 Qr 20 yards of each other, the third was back about 50 yards. When the lead tank was about 40 or 50 yards away from the bridge, the two Company "A" bazooka teams got up just like clock work to the edge of the road. They were under the heaviest small arms fire from the other side of the causeway, and from the cannon and machine gun fire from the tanks. To this day, I’ll never be able to explain why all four of them were not killed. They fired and reloaded with the precision of well-oiled machinery. Watching them made it hard to believe that this was nothing but a routine drill. I don’t think that either crew wasted a shot. The first tank received several direct hits. The treads were knocked off, and within a matter of minutes it was on fire. Then they went to work on the second tank, and within about 30 seconds, it was on fire. They fired every rocket that they had and then jumped into their foxholes. The 57mm during this time was firing and eventually knocked out the last tank. The gun crew did an excellent job.

My two bazooka crews called for more ammunition. Major Kellam ran up toward the bridge with a bag of rockets followed by Captain Roysden. When they were within 15 or 20 yards of the bridge, the Germans opened up with mortar fire on the bridge. Major Kellam was killed and Captain Roysden was rendered unconscious from the concussion. He died later that day. Both of the bazookas were destroyed by the mortar fire. Lt. Weir (Reg. Hq. Co.) and I carried Captain Roysden back. I then took over command of the battalion, being the senior officer present.

Company "B" was put into reserve in the perimeter of Company "A", so that we had almost a 560 degree perimeter defense. The rest of the day we were under heavy mortar and machine gun fire. The mortar fire was very effective as against the two forward platoons because of tree bursts. It took very little imagination on the part of the Krauts to figure out just where we would be dug in. As I recall, there was less than a seventy-five yard frontage on either side of the bridge from where we could effectively defend, so they could throw their mortar fin in our general direction with good results. During the night, the fire let up, but they started early the next morning and kept it up. My third platoon took the worst beating, as they were in a heavier wooded area, (tree bursts).

The second tank attack came on the afternoon of the second day. I was over on the north side of the bridge with the first platoon. For about an hour before the attack, they increased their mortar fire to the extent that the third platoon was just about knocked out, but not quite. I was not aware of this at the time. In addition to already heavy casualties, Sgt. Monahan, the platoon Sgt. was fatally wounded.

I learned second hand that some other troops had retreated through the third platoon’s position, and then through my C.P. Rumors were around that we were going to give up the bridge. As a result of this, the 57MM A.T. crew took off. I didn’t have an Executive Officer at the time. Earlier that day, he (Tom Furey) was put in command of "C" Company. My First Sergeant was a jump casualty, so my Company Headquarters at the time was non-existent except for runners and radio operators. I can’t recall why, but our radios were not working. The only way that we could communicate was through runners.

The first platoon was under heavy fire also. The platoon leader, Lt. Oakley, who had been doing an excellent job, was fatally wounded, and Sgt. Ricci was leaving the junior squad leader, Sgt. Owens, in command. You will recall that we have had some communication about Sgt. Owens in the past as to his personal courage and the way he commanded the platoon at this most critical time. I recommended Sgt. Owens and my tour bazooka men for the D.S.C. The bazooka men were awarded the D.S.C., but Sgt. Owens was not. This is a story in itself.

The second attack was with two tanks and infantry. I was unable to estimate the size. The tanks stayed out of effective bazooka range. (We had one bazooka left.) Not hearing any fire from the 57MM, I went over to it and found it unmanned. I tried to fire it, but the crew had taken the firing mechanism. I organized five or six men behind the hedge on the southerly side of the road with Gammon grenades, and just about this time, two of the gun crew returned with the firing mechanism. They knocked out the two tanks. They were two youngsters not more than 17 or 18 years old, who returned on their own initiative. I recommended them for Silver Stars.

The rest of our stay at the bridge was uneventful, except for the continued mortar fire, and at the end, artillery fire which damaged the 57MM. Lt. Col. Mark Alexander took over command of the battalion later that day and continued to command it for most of the operation. Without exception, he was the finest battalion commander I ever served under. My second son, Mark Alexander Dolan, was named after him.

In conclusion, we held the bridge until relieved. In Co. "A" alone, in those days (three in all), we had seventeen known dead and about three times that number wounded. The rest of the battalion also had heavy casualties.

I have tried to give you an accurate picture of what happened however, after fifteen years, the foregoing may contain some minor inaccuracies I will be glad to give Mr. Ryan any additional information he may require. You may assure him that I will be happy to cooperate with him in every detail.

Very truly yours,

JJD:eg

P.S. Since writing this Letter, I have read the account by David Howarth in the Saturday Evening Post, and I agree with you that it contains many inaccuracies. You will probably note that some of the events related tie in with what I have told you in this letter.

The most glaring inaccuracy is about the bridge being lost. For the record, this bridge was held by Company "A" from the time of its capture on "D" Day, until we were relieved.

The battle around La Fière Bridge

When the main Airborne force landed around midnight Robert Murphey’s job as a pathfinder was done. He had marked the way for the others and now he stayed behind on the dropzone and helped gathering the supply-bundles that had landed with the paratroopers. At first light, which must have been around eight or eight-thirty Murphey’s platoonleader 1st Lt. Lightchester (commander of the 1st Pathfinder Bn.) told him to go look for Lt. John J (Red Dog) Dolan. Lt. Dolan was the commander of A Co. at that time. This company’s goal was to take and hold the La Fière Bridge.

The La Fiere bridge is located just west of Ste. Mere d’Eglise, the primary target of the 82nd Airborne Division. The bridge runs across the small river the Merderet. Holding the bridge ment holding the western entrance of ste. Mere d’Eglise.

This city was so important because it was the crossing of the road from Carentan to Cherbourg and the road running from the west side of the peninsula to the beach that was code-named Utah Beach. If the Germans wanted to launch a full scale counterattack on the men coming in on the beaches from the sea, then they certainly had to bypass ste. Mere d’Eglise at La Fière Bridge. A large German counterattack in the first hours of the invasion could endanger the whole operation.

When Murphey arrived at the bridge, a defense-line had already been established. The paratroopers had pulled a German truck onto the bridge, to prevent any vehicles from passing. Anti-tank mines were laid in front of the truck to add to the roadblock.

The Germans had flooded the grasslands, prior to the invasion and the road alone was the sticking out above the water, because it was on a dike. Parachutes and supply-bundles could be see floating in the water and it was obvious that paratroopers had drowned in these fields on landing. The paratroopers had no choice then to dig in on the sides of the road, and even their they could dig very deep without getting water in their foxholes.

The artillery support that the defenders had was only one 57mm canon that had been flown in by glider. Murphey was not the only soldier joining the men from A Co. at that time. A group of soldiers from the 508th had been trapped in Coccagny during the night and had now gotten away and pulled back across the bridge.

Just as the men from the 508th had crossed the bridge, German 88th’ s were zeroing in on the bridge. These shells were particularly feared by the Americans because you couldn’t hear them coming in. Mortar shells and rockets also started to land within the American defense-line.

Three German tanks advanced towards the bridge as soon as the shelling had stopped. It were French Renault tanks which the Germans had captured during their drive into France in 1940. Although not very modern they still posed a serious threat for the weakly armed Airborne soldiers. The infantry followed the tanks in their advance, using the tanks as cover.

Two American bazooka-teams jumped up as soon as the tanks got within range. Each team had two men, one aimer and one loader. John D Boldison and Gordon Poya made the first team and Leonard Peterson, a Swedish airborne soldier that barely spoke English and Marcus Huyme made the second team. The aimers had to stand-up in their foxholes when they fired their bazooka’s. This ment that they had to expose themselves to all enemy fire. The didn’t pay attention to the German fire and placed several hits on the first two tanks, disabling both. The third tank also received some damage, but it managed to pull back.

A German officer climbed out of the first tank, in an attempt to run off to safety. There was not much feeling of compassion with the Germans among the Airborne soldiers and several men opened fire on the officer as soon as he had lifted himself from on the turret. The officer was killed at the spot.

The Infantry also remained at a distance once they had lost the support of their tanks. The battle was still far from being over. More critical hours were still ahead of A Co. of the 505th Parachute Infantry Regiment. Relief came in the night of June 8th. The 325th Glider Infantry Regiment of the same 82nd Airborne division took the positions at the bridge over from A Co. By that time more canons had been brought in for the paratroopers. For Robert Murphey the relief ment the end of his activities in Normandy. He had been hit by shrapnel in his back as a result from the continuous German shelling. He was taken back to England where he spend several weeks in a hospital.

© normandy44

To all fans, my book, "From Toccoa to the Eagle’s Nest: Discoveries in the Boosteps of the Band of Brothers" is now available on Amazon, Booksurge and Alibris Thanks Dalton

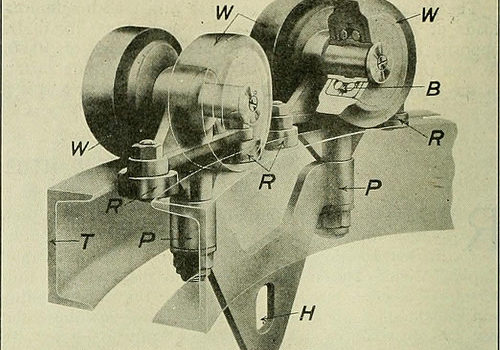

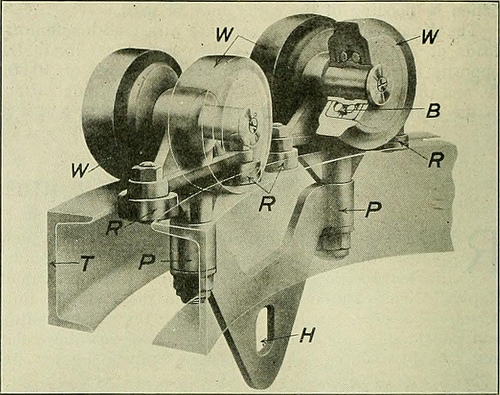

Image from page 87 of “Transactions of the Society of Motion Picture Engineers (1921)” (1921)

Image by Internet Archive Book Images

Identifier: transactionsofso12soci_0

Title: Transactions of the Society of Motion Picture Engineers (1921)

Year: 1921 (1920s)

Authors: Society of Motion Picture Engineers

Subjects: motion pictures

Publisher: Society of Motion Picture Engineers

Contributing Library: Library of Congress, MBRS, Moving Image Section

Digitizing Sponsor: Library of Congress, Motion Picture, Broadcasting and Recorded Sound Division

View Book Page: Book Viewer

About This Book: Catalog Entry

View All Images: All Images From Book

Click here to view book online to see this illustration in context in a browseable online version of this book.

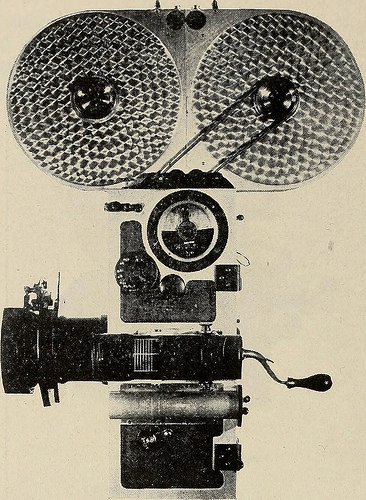

Text Appearing Before Image:

of f3.5 and is set in an accurate focusing mount. The new model of the professional Debrie Camera appears out-wardly much the same as formerly, but is now equipped with auto-matic shutter dissolve and a number of minor refinements in con-struction and design. The French Pathe Camera remains practically the same asbefore the war but the American Pathe which is the name frequentlyapplied to the Wilart Camera, has forged ahead so consistenly thatthe old simile no longer applies. Even the old familiar form of the studio model with overheadexterior magazines will soon become a thing of the past for the newmodel of the Wilart Camera which will appear shortly has lines dis-tinctively its own and the magazines will be placed inside the camera so that it can be taken from its case threaded ready for operation. Some of the advantages of the present Wilart model over thePathe are as follows: all metal construction, automatic shutter dis-solve, all metal film race, automatic opening light traps,

Text Appearing After Image:

Side elevation of Wilart Camera. view finder, improved focusing mechanism, ball bearings, Veedercounter, interior masks, etc. The Wilart Instrument Company is about to put on the marketa small motion picture camera using half width film for home usewhich they expect will have many commercial applications as well.This camera, called the Arcograph, looks like a miniature model ofthe Bell & Howell and is made with the same care and precision asa professional camera. The pictures made by this little instrumentare one-quarter the standard size and the projector of portable typewith a reel of film ready threaded is about the size of a lunch boxor a bag for a mans bathing suit. The Universal Camera sold by Burke & James now has anautomatic shutter dissolve built into the camera and a turret attach-ment for carrying extra lenses is now available. The American Motion Picture Machine Company of LongIsland City have recently brought out a turret for four lenses whichthey attach to the Pa

Note About Images

Please note that these images are extracted from scanned page images that may have been digitally enhanced for readability – coloration and appearance of these illustrations may not perfectly resemble the original work.