Merc is a globe-class precision engineering business creating high quality precision parts & sub-assemblies to consumer specifications. Primarily based in Barrowford, …

Video Rating: three / 5

engineering

Speed up production: CNC Engineering

Time is 1 of the most crucial aspects in human life nowadays in each aspect. Men and women sustain time for performing specific jobs. In early instances with the lacking of technologies and machines folks had to manually do the exact same function with sheer manpower which made it time costly in those days. These days there are many machines and equipments which are utilized by people to get their operate simplified and more rapidly. Functions such as constructions, productions, manufacturing of components, and so forth can be simplified and be carried out faster with the use of specific equipments and devices. In today’s life every person want to get their job accomplished as fast as attainable and with most facilities.

In the aspect of production, the same can be applied. There is a vast development of the economy of the globe as a whole from the previous years. As much more and more population goes on growing, more and far more demand increases and there are developed far more pressure on production in a limited time. In product a variety of sort of machines and equipment are employed to handle as well as carry production method. In the early times only human with their manpower did all the perform in the absence of technology but presently with the advancement of technologies, computerized machinery, devices and equipments are offered and are used in every manufacturing procedure to speed up the time of production as effectively as to reduced the number of labors to be utilised.

With the advancement of technologies CNC machines are being created presently to help the production process as nicely as many other locations. CNC stands for computer numerical handle which refers to automation of the machines with the use of programming which can be controlled by levers, hand wheels, buttons, etc. In the system of CNC elements are hugely automated making use of CAD (personal computer aided design and style) and CAM (laptop aided manufacturing). There are numerous organizations that practices CNC engineering in generating CNC machines and devices. These systems are mainly used in cutting of metals and materials like stainless steel, brass, and aluminum, steel, copper and several far more.

An additional engineering which is sub disciplined to electronics engineering, electrical engineering, optical engineering and mechanical engineering is precision engineering. This variety of engineering is concerned with the development of machines, devices, fixtures, and so on which will have really low tolerance in respect to physical dimension, property, material, etc. CNC machining not only aids in speeding up the production approach but also makes certain that the production goes as calculated i.e. it offers precise measurements of the item being made.

For more details about CNC Machining and Precision Engineering go to our site – http://www.attardengineering.com.au/

Locate A lot more Cnc Engineering Articles

Mechanical Engineering

Mechanical engineering plays an essential role in enhancing safety, enjoyment, financial vitality and all round high quality of life throughout the world. Mechanical engineers are concerned with the principles of force, energy and motion. Those who operate as mechanical engineers are professionals with professional information of the manufacture and design of mechanical systems and thermal devices and processes. Some examples of approach and merchandise created by mechanical engineers consist of engines and control systems for electric power generation plants, automobiles and aircraft, lifesaving medical devices and consumer items ranging from air conditioners to private computer systems and athletic equipment. They also design the machines that mass-make these items. Practically every single aspect of life is touched by mechanical engineering. If some thing moves or utilizes power, a mechanical engineer was most likely involved in its design and style or production. The explosive development and expansion in laptop technologies has changed the face of mechanical engineering literally.

The drawing board has offered way to laptop aided- design and style (CAD), and sophisticated computational software program tools have enabled mechanical engineers to create efficient options to complex technical issues. For e.g., the emerging high-tech field of nano technology is attracting mechanical engineers to design and style ultra-miniature machines and tiny implantable medical devices that navigate the human body browsing for broken tissue and illness. Also, the growing concern for the planet and the high quality of life for future generations have spurred continuing efforts by mechanical engineers to design resource-effective and recyclable items and develop gear and processes to clean-up current environmental issues and stop their reoccurrence. These technologies and a host of others will have an influence on lives in the 21st century, and their improvement and refinement call for the expertise, intuition and creative ability of mechanical engineers. At the very same time, mechanical engineers are expected to comprehend and convey the actual-globe consequences of technology improvement alternatives to decision-makers and the public.

Mechanical engineering is a profession requirements some particular skills. These abilities are acquired by way of education, training and encounter. All through higher college, students need to enroll in particular courses as preparation for acceptance into engineering programs at a college or university. A solid foundation in mathematics, science and the language arts is essential. Sturdy mathematics preparation includes algebra, geometry, trigonometry and calculus. Chemistry, biology and physics type the simple science foundation. Capability in oral and written communications is critical to good results in mechanical engineering studies, and courses in mechanical or pc-aided drafting/drawing and other technologies-connected subjects can assist students begin to realize the important practicalities of technological projects. Students can improve their studies and enrich the overall learning experience by getting into science and technologies fairs and design competitions, and by joining clubs or career groups devoted to engineering and science. Some clubs sponsor day trips and similar excursions to organizations, laboratories and industrial facilities, where students can meet engineers in actual operate environments.

For help with your Mechanical Engineering Homework Aid you can go to classof1.com

Classof1.com is open 24/7. You can get in touch with us at 1-877-252-7763 or drop an email to understanding@classof1.com

Locate A lot more China Mechanical Engineering Articles

Fadec Engineering LLC UMC10 CNC Mill Introduction video.

This video shows how aggressive the UMC10 CNC Mill can be with its 500ipm+ Speedy Travels, and servo drive motors that can truly push the cutting tools and m…

Most recent Cnc Precision Engineering News

Marilynne Robinson on Freedom of Thought

It is strangely effortless to forget that they have been capable of complex engineering, though so numerous of their monuments nonetheless stand. The Babylonians utilised quadratic equations. However in numerous instances ancient people … Science may well note with excellent care and …

Study much more on Truth-Out

Renewed Consolidation Named For Taiwan Bourse

Amongst the actives, Taiwan Semiconductor Manufacturing Company surged 3.20 percent, even though Sophisticated Semiconductor Engineering jumped 2.91 percent, Siliconware Precision Industries climbed 2.54 percent, Hon Hai Precision Industry added .53 …

Study far more on Nasdaq

Beach Company: Starting Oct. 23

Trelleborg Sealing Options is one of the planet's leading developers, makers and suppliers of precision seals and bearings with more than 20 production facilities and a lot more than 40 advertising and marketing companies worldwide. In the U.S., the new offices …

Study much more on Beach Reporter

TARA Biosystems and Harris & Harris Group Type Business to Improve Security …

"Through this investment, we are taking a top 3-D tissue engineering and drug discovery platform from the laboratory into commercial development," mentioned Misti Ushio, Ph.D., founding CEO of TARA Biosystems and Managing Director of Harris & Harris …

Read much more on MarketWatch

Cool Precision Engineering Services images

A couple of good precision engineering solutions images I identified:

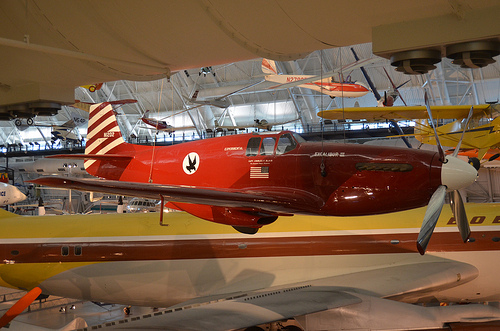

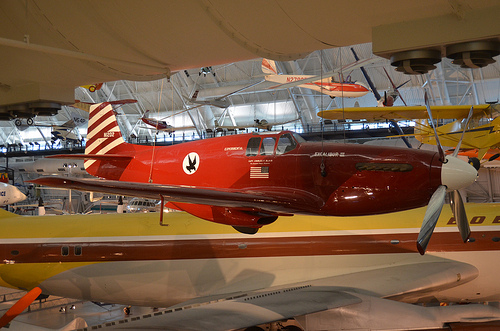

Steven F. Udvar-Hazy Center: North American P-51C, “Excalibur III”

Image by Chris Devers

Quoting Smithsonian National Air and Space Museum | North American P-51C, "Excalibur III":

On May possibly 29, 1951, Capt. Charles F. Blair flew Excalibur III from Norway across the North Pole to Alaska in a record-setting 10½ hours. Utilizing a technique of cautiously plotted "sun lines" he developed, Blair was capable to navigate with precision where conventional magnetic compasses usually failed. Four months earlier, he had flown Excalibur III from New York to London in much less than eight hours, breaking the current mark by over an hour.

Excalibur III first belonged to famed aviator A. Paul Mantz, who added further fuel tanks for lengthy-distance racing to this regular P-51C fighter. With it Mantz won the 1946 and 1947 Bendix air race and set a transcontinental speed record in 1947 when the airplane was named Blaze of Noon. Blair purchased it from Mantz in 1949 and renamed it Excalibur III, following the Sikorsky VS-44 flying boat he flew for American Export Airlines.

Present of Pan American Globe Airways

Manufacturer:

North American Aircraft Organization

Date:

1944

Nation of Origin:

United States of America

Dimensions:

Wingspan: 11.three m (37 ft)

Length: 9.eight m (32 ft three in)

Height: 3.9 m (12 ft 10 in)

Weight, empty: four,445 kg (9,800 lb)

Weight, gross: five,052 kg (11,800 lb)

Leading speed: 700 km/h (435 mph)

Components:

All round: Aluminum

Physical Description:

Single seat, single engine, low wing monoplane, World War II fighter modified for racing.

• • • • •

Quoting Smithsonian National Air and Space Museum | Boeing 367-80 Jet Transport:

On July 15, 1954, a graceful, swept-winged aircraft, bedecked in brown and yellow paint and powered by 4 revolutionary new engines very first took to the sky above Seattle. Constructed by the Boeing Aircraft Company, the 367-80, better recognized as the Dash 80, would come to revolutionize commercial air transportation when its developed version entered service as the renowned Boeing 707, America’s 1st jet airliner.

In the early 1950s, Boeing had begun to study the possibility of making a jet-powered military transport and tanker to complement the new generation of Boeing jet bombers entering service with the U.S. Air Force. When the Air Force showed no interest, Boeing invested million of its own capital to build a prototype jet transport in a daring gamble that the airlines and the Air Force would purchase it when the aircraft had flown and proven itself. As Boeing had accomplished with the B-17, it risked the business on one particular roll of the dice and won.

Boeing engineers had initially based the jet transport on studies of improved styles of the Model 367, greater recognized to the public as the C-97 piston-engined transport and aerial tanker. By the time Boeing progressed to the 80th iteration, the style bore no resemblance to the C-97 but, for security causes, Boeing decided to let the jet project be identified as the 367-80.

Function proceeded rapidly after the formal commence of the project on Might 20, 1952. The 367-80 mated a big cabin based on the dimensions of the C-97 with the 35-degree swept-wing design and style based on the wings of the B-47 and B-52 but considerably stiffer and incorporating a pronounced dihedral. The wings were mounted low on the fuselage and incorporated high-speed and low-speed ailerons as properly as a sophisticated flap and spoiler method. Four Pratt & Whitney JT3 turbojet engines, every producing ten,000 pounds of thrust, had been mounted on struts beneath the wings.

Upon the Dash 80’s very first flight on July 15, 1954, (the 34th anniversary of the founding of the Boeing Firm) Boeing clearly had a winner. Flying 100 miles per hour more rapidly than the de Havilland Comet and drastically larger, the new Boeing had a maximum variety of a lot more than 3,500 miles. As hoped, the Air Force bought 29 examples of the style as a tanker/transport after they convinced Boeing to widen the design and style by 12 inches. Happy, the Air Force designated it the KC-135A. A total of 732 KC-135s have been built.

Speedily Boeing turned its consideration to selling the airline sector on this new jet transport. Clearly the business was impressed with the capabilities of the prototype 707 but never a lot more so than at the Gold Cup hydroplane races held on Lake Washington in Seattle, in August 1955. For the duration of the festivities surrounding this occasion, Boeing had gathered many airline representatives to appreciate the competitors and witness a fly previous of the new Dash 80. To the audience’s intense delight and Boeing’s profound shock, test pilot Alvin "Tex" Johnston barrel-rolled the Dash 80 more than the lake in complete view of thousands of astonished spectators. Johnston vividly displayed the superior strength and overall performance of this new jet, readily convincing the airline market to acquire this new airliner.

In browsing for a marketplace, Boeing discovered a ready client in Pan American Airway’s president Juan Trippe. Trippe had been spending considerably of his time searching for a appropriate jet airliner to enable his pioneering business to sustain its leadership in international air travel. Operating with Boeing, Trippe overcame Boeing’s resistance to widening the Dash-80 design, now known as the 707, to seat six passengers in each and every seat row rather than 5. Trippe did so by putting an order with Boeing for 20 707s but also ordering 25 of Douglas’s competing DC-eight, which had but to fly but could accommodate six-abreast seating. At Pan Am’s insistence, the 707 was made 4 inches wider than the Dash 80 so that it could carry 160 passengers six-abreast. The wider fuselage created for the 707 became the common design for all of Boeing’s subsequent narrow-body airliners.

Despite the fact that the British de Havilland D.H. 106 Comet and the Soviet Tupolev Tu-104 entered service earlier, the Boeing 707 and Douglas DC-eight were larger, quicker, had higher variety, and have been much more profitable to fly. In October 1958 Pan American ushered the jet age into the United States when it opened international service with the Boeing 707 in October 1958. National Airlines inaugurated domestic jet service two months later utilizing a 707-120 borrowed from Pan Am. American Airlines flew the 1st domestic 707 jet service with its personal aircraft in January 1959. American set a new speed mark when it opened the initial regularly-scheduled transcontinental jet service in 1959. Subsequent nonstop flights in between New York and San Francisco took only 5 hours – three hours less than by the piston-engine DC-7. The one-way fare, like a surcharge for jet service, was five.50, or 1 round trip. The flight was almost 40 % more rapidly and almost 25 percent less expensive than flying by piston-engine airliners. The consequent surge of traffic demand was substantial.

The 707 was originally designed for transcontinental or one particular-stop transatlantic range. But modified with added fuel tanks and a lot more effective turbofan engines, the 707-300 Intercontinental series aircraft could fly nonstop across the Atlantic with complete payload beneath any conditions. Boeing constructed 855 707s, of which 725 had been bought by airlines worldwide.

Possessing launched the Boeing Company into the industrial jet age, the Dash 80 soldiered on as a hugely successful experimental aircraft. Until its retirement in 1972, the Dash 80 tested quite a few sophisticated systems, a lot of of which were incorporated into later generations of jet transports. At one particular point, the Dash 80 carried 3 distinct engine kinds in its four nacelles. Serving as a test bed for the new 727, the Dash 80 was briefly equipped with a fifth engine mounted on the rear fuselage. Engineers also modified the wing in planform and contour to study the effects of various airfoil shapes. Quite a few flap configurations have been also fitted like a hugely sophisticated technique of "blown" flaps which redirected engine exhaust more than the flaps to enhance lift at low speeds. Fin height and horizontal stabilizer width was later improved and at 1 point, a specific multiple wheel low pressure landing gear was fitted to test the feasibility of operating future heavy military transports from unprepared landing fields.

After a lengthy and distinguished profession, the Boeing 367-80 was finally retired and donated to the Smithsonian in 1972. At present, the aircraft is installated at the National Air and Space Museum’s new facility at Washington Dulles International Airport.

Gift of the Boeing Organization

Manufacturer:

Boeing Aircraft Co.

Date:

1954

Nation of Origin:

United States of America

Dimensions:

Height 19′ two": Length 73′ 10": Wing Span 129′ eight": Weight 33,279 lbs.

Physical Description:

Prototype Boeing 707 yellow and brown.

Newest Precision Engineering Components News

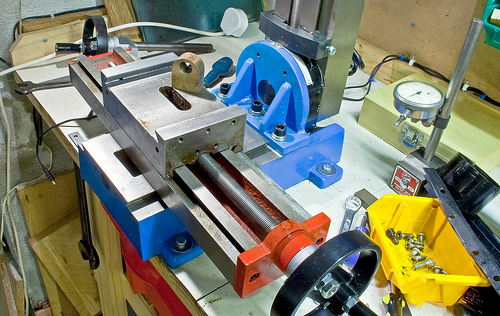

Mini Mill Table Components

Image by tudedude

Table tipped upside down on the bed, the tiny brass bit is the nut for the lead screw.

Report: “Multi-Modal Level of Service” Metrics Not Quite Up to the Challenge

Level of Service is a common, simplistic engineering measure that makes use of car throughput to assign streets a letter grade from A to F. For almost 60 years, LOS has been the predominant way that planners and engineers quantify streets. LOS guides …

Read far more on Streetsblog Los Angeles (blog)

Neil Carmichael MP sees provide chain achievement at Cam's TJW Precision …

TJW Precision Engineering is a supplier of precision elements to international aerospace firm Airbus, manufacturing parts for their effective A320. In the course of the go to Neil Carmichael MP was shown about by Managing Director Gary Cowle and …

Study a lot more on Stroud News and Journal

Relating Machine Accuracy and Dynamics to Low Damage Grinding

When these forces act on compliant components, they produce differences in the depth of reduce and also restrict the surface high quality. … of AMT (The Association of Manufacturing Technology) and has corporate affiliations with a number of specialist …

Study a lot more on Azom.com

Nice Precision Engineering Services photos

Verify out these precision engineering solutions pictures:

Steven F. Udvar-Hazy Center: Lockheed Martin X-35B Joint Strike Fighter, with other modern day jet aircraft

Image by Chris Devers

Quoting Smithsonian National Air and Space Museum | Lockheed Martin X-35B STOVL:

This aircraft is the initial X-35 ever constructed. It was initially the X-35A and was modified to include the lift-fan engine for testing of the STOVL notion. Amongst its several test records, this aircraft was the very first in history to obtain a quick takeoff, level supersonic dash, and vertical landing in a single flight. It is also the first aircraft to fly utilizing a shaft-driven lift-fan propulsion program. The X-35B flight test system was 1 of the shortest, most effective in history, lasting from June 23, 2001 to August 6, 2001.

The lift-fan propulsion technique is now displayed next to the X-35B at the Steven F. Udvar-Hazy Center near Dulles Airport.

On July 7, 2006, the production model F-35 was officially named F-35 Lightning II by T. Michael Moseley, Chief of Staff USAF.

Transferred from the United States Air Force.

Date:

2001

Dimensions:

Wing span: ten.05 m (33 ft in)

Length: 15.47 m (50 ft 9 in)

Height: about 5 m (15 ft in)

Weight: about 35,000 lb.

Components:

Composite material aircraft skin, alternating steel and titanium spars. Single-engine, single-seat configuration involves lift-fan and steering bars for vertical flight.

Physical Description:

Quick takeoff/vertical landing variant to be utilized by U.S. Air Force, U.S. Marines and the United Kingdom, equipped with a shaft-driven lift fan propulsion program which enables the aircraft to take off from a quick runway or small aircraft carrier and to land vertically.

Engine: Pratt & Whitney JSF 119-PW-611 turbofan deflects thrust downward for brief takeoff/vertical landing capability. The Air Force and Navy versions use a thrust-vectoring exhaust nozzle. The Marine Corps and Royal Air Force/Navy version has a swivel-duct nozzle an engine-driven fan behind the cockpit and air-reaction manage valves in the wings to offer stability at low speeds.

Other major subcontractors are Rolls Royce and BAE.

• • • • •

Quoting Smithsonian National Air and Space Museum | Grumman A-6E Intruder:

The Navy’s knowledge in the Korean War showed the need for a new extended-range strike aircraft with high subsonic efficiency at quite low altitude–an aircraft that could penetrate enemy defenses and uncover and destroy little targets in any climate. The Grumman A-six Intruder was created with these wants in mind. The Intruder initial flew in 1960 and was delivered to the Navy in 1963 and the Marine Corps in 1964.

The Navy accepted this airplane as an "A" model in 1968. It served below harsh combat conditions in the skies more than Vietnam and is a veteran of the 1991 Desert Storm campaign, when it flew missions for the duration of the initial 72 hours of the war. It has accumulated more than 7,500 flying hours, more than 6,500 landings, 767 carrier landings, and 712 catapult launches.

Transferred from the United States Navy, Workplace of the Secretary

Date:

1960

Country of Origin:

United States of America

Dimensions:

Overall: 16ft 2in. x 52ft 12in. x 54ft 9in., 26745.8lb. (four.928m x 16.154m x 16.688m, 12131.8kg)

Components:

Conventional all-metal, graphite/epoxy wing (retrofit), aluminium control surfaces, titanium high-strength fittings (wing-fold).

Physical Description:

Dual place (side by side), twin-engine, all-weather attack aircraft a number of variants.

Mayville Engineering Firm, Inc. (MEC) Named One of Wisconsin’s Largest Closely Held Companies

Mayville, Wis. (PRWEB) October 09, 2014

Mayville Engineering Business, Inc. (MEC) was recognized at the annual Wisconsin 75 event as becoming 1 of the largest closely held organizations in the state. The business has substantial operations in Wisconsin with manufacturing facilities in Mayville, Beaver Dam, Neillsville and Wautoma. MEC operates 17 facilities in five states with over two,000,000 sq. ft. of manufacturing. The firm is one hundred% employee owned with more than two,000 employee shareholders.

The Wisconsin 75 system is an annual listing of the largest closely held companies headquartered in Wisconsin. The plan recognizes company contributions to the communities in which the firms are situated, the men and women who develop the company and the all round Wisconsin economy.

“We’re pleased to be recognized as one particular of the largest closely held firms in Wisconsin,” mentioned Robert Kamphuis, chairman, president and CEO of MEC. “I’m proud of our employee shareholders and I want to thank Deloitte, the Milwaukee Journal Sentinel, and the Wisconsin 75 program for this acknowledgment of MEC’s continued profitable growth,” he continued.

Representatives of MEC have been on hand at the occasion in Milwaukee exactly where Milwaukee Bucks co-owner, Marc Lasry, made the keynote address to the distinguished group of Wisconsin organization leaders. This is the tenth year that MEC has been recognized as becoming one particular the largest closely held organizations in the state and element of the Wisconsin 75 list.

Check out http://www.mecinc.com for far more details on MEC’s revolutionary contract manufacturing, tube forming, metal fabrication, coatings and assembly solutions.

###

About Mayville Engineering Business

Headquartered in Mayville, Wis., MEC has grow to be a manufacturing organization exactly where employee shareholders are making outstanding value and support every day for their customers and communities in which they reside and work. MEC serves the agricultural, commercial automobile, construction, forestry, on/off road energy sports cars, energy, military, and industrial markets. MEC’s processes include full metal fabrication, laser and plasma cutting, stamping, forming, machining, welding, tube bending and forming, painting, polishing, brazing, cleaning, assembly and kitting, prototyping, solution testing and validation, fluid level indicators, stoppers, engine tubes, suction tubes, hydraulic tubes, discharge tubes, fill tubes, higher temp coatings, metal encapsulated insulation, fuel tanks, air brake tanks, air intake and exhaust systems. The firm’s core competencies include collaborative item development, design for manufacturability, engineering and design assessment, project management and client service. MEC operates 17 facilities with more than two,000,000 square feet of manufacturing in Michigan, Mississippi, South Carolina, Virginia and Wisconsin. A lot more data can be discovered at http://www.mecinc.com.

Connected Machining Metal Parts Press Releases

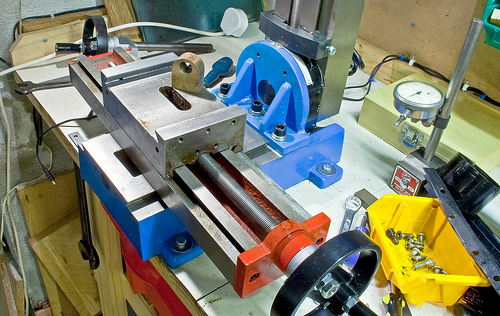

Good Precision Engineering Components pictures

Some cool precision engineering elements images:

Helping hands

Image by tudedude