Cincinnati, OH (PRWEB) December 03, 2014

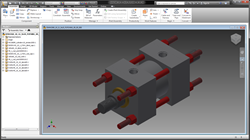

Milwaukee Cylinder has launched their ISO Metric line of hydraulic cylinders inside their on-line 3D product catalog. Identified as MILCAD, the on the internet catalog was designed and constructed by CADENAS PARTsolutions, and provides on-demand access to 3D CAD models of Milwaukee Cylinder merchandise to engineers worldwide.

A Wisconsin based manufacturer of hydraulic and pneumatic components, Milwaukee Cylinder maintains technological innovation and consumer service as their highest priorities, with the on the internet catalog as a essential element for each. The ISO Metric line of hydraulic tie rod cylinders is an important addition to their online solution lineup. This line conforms to the ISO 6020-two normal and is made particularly as a domestic solution for designers searching for a replacement for merchandise they formerly would have had to source from overseas.

CADENAS PARTsolutions specializes in helping industrial companies gain marketplace share and fostering a exceptional customer knowledge by using digital 3D item catalogs and configurators.

In the previous, engineers would have had to speak to the manufacturer directly, by phone or e mail, when seeking for certified CAD models of Milwaukee Cylinder items. Now, with their addition to the MILCAD 3D product catalog interface, engineers can quickly configure and spec these into their design and style, any time of day or night.

“With this new addition we’re offering our customers a domestic source option for metric cylinders and a digital supply to very easily specify them,” says Douglas Lacina, Advertising and marketing and Engineering Leader at Milwaukee Cylinder. “By getting domestic, it offers consumers the opportunity to work with an individual in or close to their time-zone, assisting the capacity for consumers to speak actual time with cylinder design and application authorities. We’re also removing hurdles by supplying instant access to MILCAD, our 3D CAD models and quoting tool. MILCAD generates a 3D CAD model in practically any format preferred, or a 2-D PDF drawing, it also offers the potential to rapidly get a quote. Merely configure your solution and hit the quote button. Engineers and designers of machinery and assemblies favor to download 3D CAD models of the elements they source for their digital design. This increases the accuracy of their design, due to the fact the manufacturer creates and certifies the models.

“It’s far more than true time communications with a world class supplier, that’s going to have Milwaukee Cylinder buyers excited,“ adds Rob Zesch, President and COO of CADENAS PARTsolutions. “Design accuracy is paramount. By making use of these time-saving models, customers will have a considerably more precise design and style. Users no longer have to ‘eyeball’ or create models from a list of specs, they can download cost-free models which are certified correct by Milwaukee Cylinder.”

About Milwaukee Cylinder

The Milwaukee Cylinder Company is a complete line manufacturer of tough, industrial hydraulic and pneumatic cylinders and accessories. Situated in Cudahy WI, Milwaukee Cylinder has been a leader in the business because 1956, and is ISO 9001:2008 certified. Besides being identified for its normal line of high high quality tie rod cylinder products, Milwaukee Cylinder has created a worldwide reputation for engineering experience in the manufacture of specialty cylinders. Over the last 50 years, Milwaukee Cylinder has turn into known as the organization exactly where “Specials Are Our Standard”. http://www.milwaukeecylinder.com

About CADENAS PARTsolutions

CADENAS PARTsolutions is a top provider of subsequent generation 3D element catalog management and sales configuration solutions. For massive producers, CADENAS PARTsolutions supplies centralized 3D regular portion catalogs creating it effortless for global design teams to discover, reuse, and manage normal and proprietary components. For component producers, CADENAS PARTsolutions supplies 3D part catalog with CAD download technology to improve sales lead generation and to make certain that elements get “designed in” to OEM merchandise. http://www.partsolutions.com/

###

Media Inquiries

CADENAS PARTsolutions

Adam Beck – Marketing and advertising Manager

400 Techne Center Dr., Ste. 301

Milford, OH 45150 USA

Telephone: (513) 453-0453

Fax: (513) 453-0460

adam.beck(at)partsolutions(dot)com

http://www.partsolutions.com

@partsolutions