If you have no idea what Printed Circuit Boards also identified as PCBs are and how PCBs are manufactured, then you are absolutely not alone. There are a lot of folks out there that have no thought what PCB manufacturing is all about. Most people have an indistinct understanding of what printed circuit boards are but when it comes to explain it to other men and women they truly are not an expert on the matter. Most folks would like to know what printed circuit boards are and how they are manufactured specially if technologies manufacturing is one of their interests.

Printed circuit boards are utilised to assist and electronically connect the connected electronic parts to the board. A couple examples of electronic components for printed circuit board are capacitors and resistors amongst many other items. These and other several electronic components are connected through conductive pathways, tracks or signal traces that are fixed from sheets of copper that are covered onto non-conductive substrate.

When a printed circuit board has the conductive and non-conductive pathways, the board is then identified as printed wiring board. Printed circuit boards are reasonably priced and yet identified to be quite trustworthy. The preliminary price is high due to the layout work that calls for a lot of investment in time and resources. Even so, printed circuit boards are still economically affective and more quickly to manufacture for anything that is of a higher volume production.

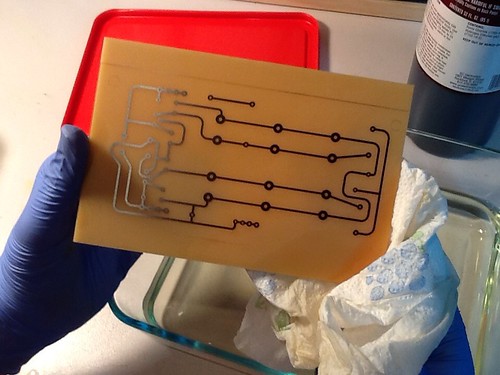

When PCBs are manufactured, the highest numbers of printed circuits are produced by bonding a copper layer over the substrate, at instances on each sides which generates a blank printed circuit board. Subsequently, the unwanted copper is removed appropriate right after the impermanent mask has been applied by etching or in layman’s term engraving. Based if the volume of manufacturing is for prototype PCB or manufacturing volume, a method of multiple electroplating will be in location which is a complex process that adds traces of substrate onto a bare substrate.

There is a assortment of approaches to take away the undesirable copper on the circuit boards in the course of manufacturing of the printed circuit boards. The top most industrial way of manufacturing volume quantities is by way of silk screen printing and the photographic way. The latter is normally utilized when the width of the lines are fine. If the manufacturing volume is little, the principal technique used is laser resist ablation making use of a CNC-mill. The most easiest and popular method employed are silk screen printing, milling and photoengraving. Nonetheless, one more common procedure that nevertheless exists and typically utilised it the addictive or semi-addictive which signifies it makes use of multilayer circuit boards due to it facilitating the plating by means of the holes.

PCB manufacturing and other numerous methods that a circuit board can merge is at instances overwhelming and frustrating. It can also be as well significantly for an individual that is not technology savvy. Even so, with pcbquotes.com you can never ever go wrong and with their assistance, you can be rest assured that you are in good capable hands.

PCB Quotes has specialized in Rapid Prototype PCB & Quickturn PCB Manufacturing. PCB Quotes will streamline your Printed Circuit Boards ordering approach and offer you rapid turn, higher quality printed circuit boards at low costs.