A few nice China turned parts china images I found:

Blade Runner Berlin

Image by Sprengben [why not get a friend]

hit “L” for a more spectacular view!

—

This is Berlin on New Years Eve. The Sony Center is a great place to be at.

At night time the whole place is lightened with different colors. The Photo is slightly surreal at least more than my previous uploads but I really like how the processing turned out. Especially the glowing lights you can see on the right and the lower parts give a special touch to this shot!

You might say this photo has too much saturation but in this case you have to believe me. It is crazy colored in the Sony Center.

Still having a lot of work to do. I work part time as a teacher for school kids in Robotics which is actually my occupation when I am finished with my Master. The three days to come the Kids are fighting to qualify themselves for the German Robocup. This is a competition where the best schools compete on each other. The winners are supposed to compete with the best schools from all over the world.

This year the World Championship in the Robocup will be held in Mexico. You can bet that I as a traveler have large interests for them to qualify for the Championship. If they do I promise you to bring you some cool photos from Central America and hopefully South America. I will keep you updated on this every now and then. So if you have a prayer… Send if for me and my pupils!

So far thanks for the overwhelming response to my images. I am happy to read from all of you even though it is tough to comment back on all your streams. Please don’t be angry if it takes some time for me to come back to your stream.

Until then have a blessed week everyone out there in the Wide Flickr World.

Ben

| Facebook | Fluidr-Interesting | Flickr Hive Mind | DNA | Blog | Twitter | Tumblr |

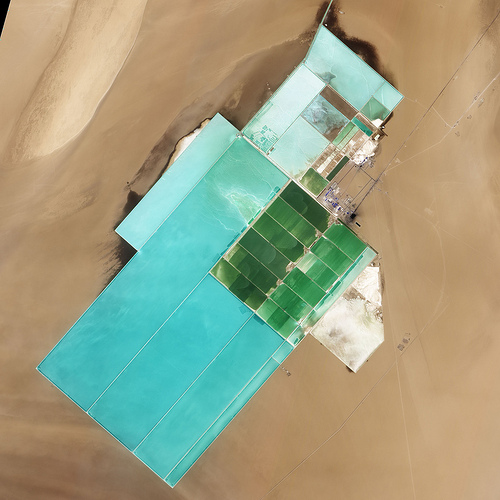

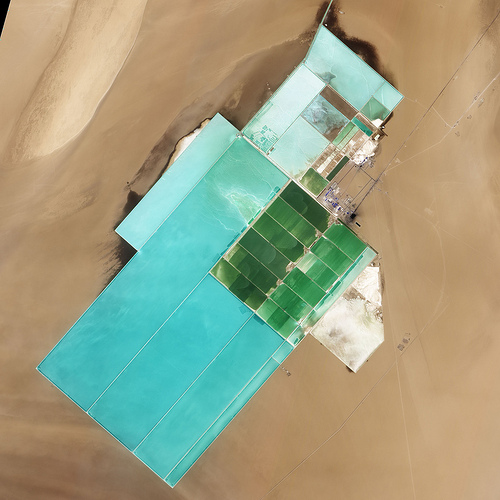

Lop Nur, Xinjiang, China

Image by NASA Goddard Photo and Video

NASA image acquired May 17, 2011

Located in China’s resource-rich but moisture-poor Xinjiang autonomous region, Lop Nur is an uninviting location for any kind of agriculture. It sits at the eastern end of the Taklimakan Desert, where marching sand dunes can reach heights of 200 meters (650 feet), and dust storms rage across the landscape.

Yet for all it lacks in agricultural appeal, Lop Nur offers something valuable to farmers the world over: potash. This potassium salt provides a major nutrient required for plant growth, making it a key ingredient in fertilizer.

The discovery of potash at Lop Nur in the mid-1990s turned the area into a large-scale mining operation. The Advanced Land Imager (ALI) on NASA’s Earth Observing-1 (EO-1) satellite captured this natural-color image of Lop Nur on May 17, 2011. The rectangular shapes in this image show the bright colors characteristic of solar evaporation ponds. Around the evaporation ponds are the earth tones typical of sandy desert.

During the early and middle Pleistocene epoch, this area held a large brackish lake. Uplift of the northern part of the lake in the late Pleistocene created hollows that became receptacles for potash deposition. The main potash deposits found at Lop Nur today are brine potash, and this site is the second-largest source of potash in China.

Lop Nur slowly dried up in the Holocene. The area now receives average annual precipitation of just 31.2 millimeters (1.2 inches), and experiences annual evaporation of 2,901 millimeters (114 inches), according to a study published in 2008. The study found, however, that this area has experienced seven major climate changes since the end of the Pleistocene, including climatic conditions far more favorable to farming and settlement than today.

Examination of plant and mollusk remains at the lake, as well as studies of sediments, indicate that the Lop Nur region experienced a severe drought about 3,000 years ago, followed by wetter conditions. Between 1,250 and 400 years ago, Lop Nur likely experienced the conditions most favorable to farming and settlement, and red willow trees grew in the area. Pottery dating from the Tang and Song dynasties further testifies to welcoming conditions at the lake centuries ago.

Starting around 400 years ago, however, a more arid climate took hold, completely drying out Lop Nur. Today, by providing potash, the desiccated lake still supports agriculture, but it does so for farming efforts further afield.

NASA Earth Observatory image created by Jesse Allen and Robert Simmon, using EO-1 ALI data provided courtesy of the NASA EO-1 team. Caption by Michon Scott.

Instrument: EO-1 – ALI

Credit: NASA Earth Observatory

NASA Goddard Space Flight Center enables NASA’s mission through four scientific endeavors: Earth Science, Heliophysics, Solar System Exploration, and Astrophysics. Goddard plays a leading role in NASA’s accomplishments by contributing compelling scientific knowledge to advance the Agency’s mission.

Follow us on Twitter

Like us on Facebook

Find us on Instagram

Turn

Image by kevinschoenmakers

Near Tagong, Sichuan province.

Part of a set: Greater Tibet.

www.kevinschoenmakers.nl