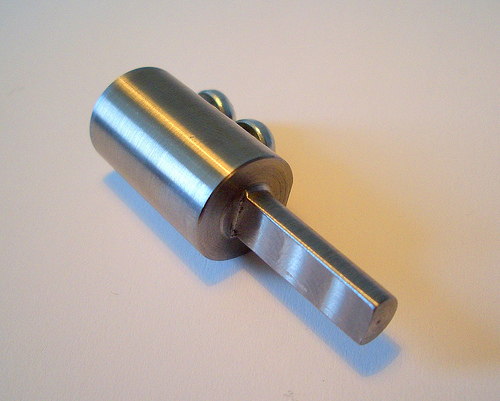

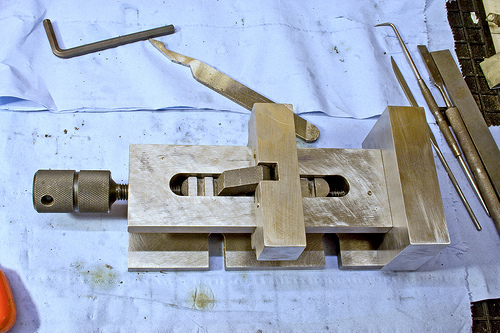

Precise surface and edge finishing are essential factors in parts China machining with individual finished parts directly affecting the successful performance of the whole machine. The edge quality of parts can be particularly essential to the smooth operation of the whole. During the molding, welding, and metal cutting processes burrs are always present. Burrs are defined as unwanted projections of the metal or other material that extend beyond the edge of the part or piece that must be removed by some method in order to attain a perfectly smooth edge.

A number of methods for deburring are commonly used including filing, sanding, brushing, barreling, chemical and thermal energy methods. Depending on the material used, the application of the part, and the precision required there can be advantages and disadvantages of any of these methods. Many of these deburring processes can be useless for difficult-to-access burrs and thick metallic burrs occurring on high strength alloys and composites. Thermal energy and electro-chemical deburring methods may be successful for these purposes, but they carry serious safety and health risks that must be considered. Other limitations of electro-chemical deburring methods may be the need for the material to be electrically conducive. Though these disadvantages are not present when using deburring machines, the machines may not be able to remove difficult or inaccessible burrs. Additionally, chemical or mechanical deburring methods can be damaging to very small parts such as computer parts and precision screws.

An ultrasonic deburring method has been developed to address these difficult and hard to remove burrs and burrs on small, sensitive parts. It uses high-energy shock waves within a compounded acid slurry or a water bath with fine abrasives added to bombard the piece. The abrasive micro-jet cutting action can successfully deburr metals to result in a finely finished surface. This process can be used on a variety of metals such as stainless steel, aluminum, copper, chrome, and nickel. It is effective in deburring precision gear teeth, needle ends, and otherwise inaccessible areas of China machined parts. Ultrasonic deburring methods are particularly suited to the removal of micro-burrs on precision molded parts.

In addition to deburring, ultrasonic methods can also effectively remove rust from iron composed parts and difficult to remove stains from external and internal surfaces. With increasingly demanding specifications for precision and cleanliness in parts, deburring methods have had to improve and develop to meet these demands. Ultrasonic deburring is being further refined as other methods are yet to be developed.

COAST METAL CUTTING (http://www.coastmetal.com/) offers a complete China machining and metal cutting service.

More Precision China Machined Parts Articles