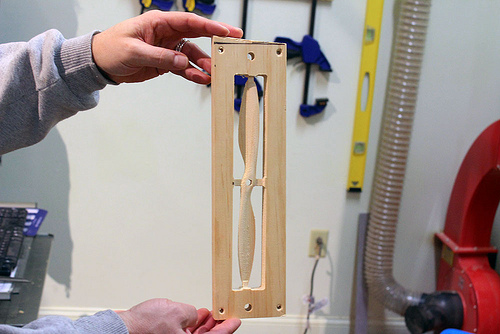

Tormach PCNC 1100! Tormach PSG! Emco V13 China Lathe! Solidworks! Sprutcam! A customer had a worn-out aluminum bracket used to drive a crank arm off a motor. Using…

Rapid Prototyping China

Tormach PCNC 1100! Tormach PSG! Emco V13 China Lathe! Solidworks! Sprutcam! A customer had a worn-out aluminum bracket used to drive a crank arm off a motor. Using…

US Air Force Memorial

Image by dbking

The United States Air Force Memorial honors the millions of patriotic men and women who have distinguished themselves in the United States Air Force and its predecessor organizations.

Some 54,000 airmen have been killed in action while serving in the Air Force and its predecessor organizations.

The Air Force is the only branch of service without any memorial in the Washington, D.C. area commemorating its service to the nation.

The Memorial is located in Arlington, Virginia at a promontory overlooking the Pentagon, the Potomac River and all of Washington, D.C.

Public Law 103-163, dated December 2, 1993 authorized the establishment of a United States Air Force Memorial on Federal land.

In lieu of any previously approved location, Public Law 107-107, dated December 28, 2001, directed the Secretary of Defense to make available the promontory land at the Naval Annex for the Memorial.

Total cost for the construction of the Memorial is in excess of M.

The Memorial was completed in September 2006, with the official dedication ceremony taking place on Saturday and Sunday, October 14 and 15, 2006.

The Spire Design

Featuring three stainless steel spires that soar skyward, the Memorial’s design is truly representative of the Air Force and is intended to evoke flight and the flying spirit.

The three spires also represent the three core values of the Air Force – integrity first, service before self, and excellence in all that is done. Equally important, they represent the Air Force’s Total Force––active, guard and reserve—which are all essential to getting the mission done.

Finally, the three spires are reminiscent of the precision “bomb burst” maneuver performed by the United States Air Force Thunderbird Demonstration Team.

The highest of the Memorial’s spires ascends 270 feet (82 meters).

The base of the Memorial is approximately 132 feet above sea level, meaning that at its highest point, the structure will stand 402 feet high.

Each spire is constructed of a ¾ inch-thick plate stainless steel skin with a core of reinforced concrete.

The Memorial was designed by James Ingo Freed, internationally renowned architect of Pei Cobb Freed & Partners. Mr. Freed is widely recognized for designing the U.S. Holocaust Memorial Museum in Washington, D.C. and other prominent structures throughout the U.S.

Global engineering firm Ove Arup & Partners worked with Pei Cobb Freed & Partners in the development of the Memorial’s spire structure.

Embedded in granite beneath the spires will be the Air Force "star," which has had a long tradition of gracing Air Force aircraft and missiles, and is central to the rank insignia of every enlisted member of the Air Force.

Other Elements

Other key elements of the Memorial include a paved Runway to Glory at the site entrance, a bronze Honor Guard statue, two granite inscription walls located at either end of a parade ground area and a Glass Contemplation Wall depicting the “missing man formation,” a final tribute paid to fallen airmen.

The Memorial’s surrounding spaces are landscaped to create a memorial park and parade ground overlooking the nation’s capital and the site also includes parking for 24 vehicles and three buses.

Internationally renowned sculptor Zenos Frudakis sculpted the Memorial’s bronze Honor Guard. The eight-foot-tall, four figure sculpture are reflective of all “Airmen,” those men and women presently serving, those that have served and those that will serve.

Mr. Frudakis’ previous works include life size sculptures of Dr. Martin Luther King, Jr. and Arnold Palmer, as well as Generals Douglas MacArthur, George C. Marshall and William Yarborough, along with many others.

The two inscription walls located at each end of a central lawn are 56 feet in length, 10 feet in height and one foot thick. They are being constructed using monolithic Jet Mist granite and both include a two and a half inch outer inscription panel made from Absolute Black granite. The south wall will honor Air Force values and campaign accomplishments (including those of the Air Force’s predecessor organizations), and the north wall will honor the valor and sacrifices made by so many “Airmen.”

The Jet Mist granite used comes from a quarry in nearby Culpepper, Virginia. The Absolute Black granite used on the outer inscription panels has been sourced from Africa and is the purest black granite found on earth.

The Glass “Missing Man” Contemplation Wall will be made out of five layers of PPG low iron (very clear) glass, which are laminated together. The assembled wall is nine feet wide and 10 feet tall.

The “Missing Man” formation is engraved on the front and back of the glass assembly and is illuminated from below. This Wall is where visitors may take a few moments to remember those that have paid the ultimate sacrifice or that have otherwise passed on.

Construction & Development

Centex Construction, LLC, of Dallas, Texas was contracted to build the Memorial.

Cianbro Corporation of Baltimore, Maryland was subcontracted to erect the Memorial’s stainless steel spires.

The ground breaking for the Memorial took place on September 15, 2004, and construction commenced on January 15, 2005.

The total weight of the spires (stainless steel, reinforcing steel and concrete) is approximately 7,300 tons (5,000 tons below ground, 2,300 tons above ground).

The Air Force Memorial’s structural design took more than one year to develop, from concept to complete detailing. The structural engineers used computer modeling validated with wind tunnel testing to assess the necessary stiffness and strength of the structure.

Because the spire structure can tend to sway during certain combinations of wind speed and direction, a “ball-in-box” damping system is utilized to mitigate the swaying effect.

A time proven engineering solution, the “ball-in-box” dampers contain 13 lead balls, each are 2,000 pounds and 20 inches in diameter encased in stainless steel shells that roll freely within octagonal boxes lined with synthetic damper pads. As the balls impact the damping pads, energy is dissipated and structural movement is constrained.

Arup’s Advanced Technology Group in the United Kingdom developed this custom system and has fine-tuned the precise dimensions and position of each of the boxes within all three spires to ensure that an appropriate level of damping is achieved.

The tallest spire contains a stack of six ball-in-box dampers, the medium spire four and the shortest spire three.

The three spire structure is supported by a system of concrete foundations, which consist of concrete caissons, concrete pile caps and concrete grade beams that extend approximately 40 feet below finished elevation.

The caissons are three feet in diameter (six feet at the belled base). The pile caps are approximately 23 feet wide and eight feet deep and range in length from 32 feet to 56 feet. The pile caps are connected by a continuous triangular grade beam, approximately eight feet wide by 16 feet deep and with a perimeter of about 300 feet. The spires are connected to the concrete foundations with a two and a half inch base plate and anchored by one and a quarter inch post-tensioned reinforcing steel bars.

A 300-foot “ringer” crane was used to install the Memorial’s three stainless steel spires.

The Air Force Memorial Foundation

The Foundation was incorporated in 1992 as a tax-exempt, charitable, historical, and educational organization. It has been granted 501(c)(3) status by the Internal Revenue Service, thus making contributions tax-exempt.

Ross Perot, Jr., President and CEO of Perot Systems and Chairman of Hillwood Development Corporation in Dallas, is Chairman of the Foundation’s Board of Trustees. There are 19 Trustees of the Foundation.

Major General Edward F. Grillo, Jr., (USAF Retired), is President of the Foundation.

Vertical Grinders Provide Precision in Small Footprint

Both machines are designed to grind small workpieces with precision. The gate structure ensures accurate China grinding by counter-measuring against vibration, thermal displacement and noise. A top beam securely connects the upper portion of the two columns, …

Read more on Modern China Machine Shop

Snowboard Designs Take Off at Never Summer With Epson SureColor F-Series …

LONG BEACH, Calif., Aug. 5, 2014 /PRNewswire/ — B.J. Slater, director of China manufacturing at Never Summer Industries, Inc. of Denver, Colo. knows the thrill of being the first snowboarder on the mountain who leaves the first tracks in the snow. He felt …

Read more on CNNMoney

History

According to most sources, the Irish Car Bomb was created in 1979 by Charles Burke Cronin Oat, current instructor at the Connecticut School of Bartending, and former owner and bartender of Wilson’s Saloon, both in Norwich, CT. The drink evolved from several earlier versions dating back to 1977. The Grandfather, the original idea behind a Car Bomb, was a mixed shot of Bailey’s and Kahla coffee liqueur. Though Guinness was also being consumed at the same time, the Grandfather was not mixed with the Guinness at the time of its creation. Shortly thereafter, Oat was inspired to add Jameson Irish Whiskey to the shot, which made the shot bubble up vigorously like an explosion, causing him to remark that “the IRA just showed up!” Hence, the newly designed shot was known as the IRA (named after the Provisional Irish Republican Army, and their use of explosions during The Troubles). Two years later while drinking IRAs and Guinness, Oat got the idea to drop the shot into his half-finished pint of Guinness, with the words “Bombs away!”, and the Irish Car Bomb was born.

The drink later spread beyond the city of Norwich due to increased advertising by Guinness beginning in the late-1980s. While Kahla was part of the original recipe, it is often dropped from the drink today. Some refer to that original recipe as a Belfast Car Bomb.

Criticism

The name Irish Car Bomb is sometimes considered offensive because of its reference to PIRA terrorism. For this reason, some bartenders refuse to serve it.

Bombs, and car bombs in particular, were the weapon of choice for the IRA during the Troubles in Northern Ireland. Perhaps the most infamous use of car bombs in Ireland’s history came on July 21, 1972 Bloody Friday. In all, 22 bombs the majority of them car bombs were set off in the city of Belfast, 19 in just over one hour. The events of Bloody Friday killed nine people (seven civilians) and resulted in 130 injuries. Bloody Friday was the deadliest day of the bloodiest year in the Troubles, as 1972 saw the explosion of 1,300 bombs.

See also

Beer cocktails

List of cocktails

Sake bomb

Jgerbomb

References

^ Irish Car Bomb recipe. Retrieved 18 Nov 2009.

^ Sennett, Bob. Complete world bartender guide. http://www.randomhouse.com/catalog/display.pperl?isbn=9780553299007.

^ Charming, Cheryl. Everything Bartender’s: 750 Recipes for Classic and Mixed Drinks, Trendy. http://www.adamsmediastore.com/product/the-everything-bartenders-book-2nd-edition?r=gbs.

^ a b “Carbomb Creation”. April 16, 2009. http://shakenwithatwist.wordpress.com/2009/04/16/carbomb-creation/. Retrieved 2009-05-18.

^ a b “The Meaning of an Irish Car Bomb”. March 11, 2009. http://paganmaid-2.livejournal.com/31682.html. Retrieved 2009-05-18.

^ a b “IrishCarBomb.com”. http://www.irishcarbomb.com/. Retrieved 2009-05-18.

^ a b “Belfast Carbomb #1”. http://www.barnonedrinks.com/drinks/b/belfast-carbomb-1-6989.html. Retrieved 2009-05-18.

^ a b Dicke, Scott (March 6, 2007). “History of Irish Car Bombs Isn’t Something to Drink To”. University of California, Santa Barbara. pp. Issue 88, Volume 87. http://www.dailynexus.com/article.php?a=13515. Retrieved 2009-05-18.

^ a b Halleron, Chris (September 28, 2005). “Hal Wastes His Wages Defuse the ‘Irish Car Bomb'”. Hudson Current. http://www.hudsonreporter.com/pages/full_story/push?article-Hal+Wastes+His+Wages+Defuse+the+-Irish+Car+Bomb-%20&id=2406564-Hal+Wastes+His+Wages+Defuse+the+-Irish+Car+Bomb-. Retrieved 2009-09-09.

^ “CAIN: Timeline of Terror”. Cain.ulst.ac.uk. http://cain.ulst.ac.uk/events/bfriday/nio/nio72.htm. Retrieved 2009-05-18.

External links

The Wikibook Bartending has a page on the topic of

Irish Car Bomb

Wilson’s Saloon, origin of the Car Bomb

v d e

Alcoholic beverages

History and production

History of alcohol

History of alcohol History of beer History of Champagne History of wine History of French wine History of Rioja wine

Production

Brewing Distilling Winemaking

Alcoholic beverages

Fermented beverage

Beer (types) Wine (types) Cider (category) Mead (category) Rice wine (category) Other fermented beverages

Distilled beverage

Brandy (category) Gin (category) Liqueur (category) Rum (category) Tequila (category) Vodka (category) Whisky (category)

Fortified wine (category)

Madeira wine (category) Marsala wine Port wine Sherry (category) Vermouth (category)

Distilled beverages by ingredients

Grain

Barley: Irish whiskey Japanese whisky Scotch whisky Maize: Bourbon whiskey Corn whiskey Tennessee whiskey Rice: Awamori Rice baijiu Soju Rye: Rye whiskey Sorghum: Baijiu (Kaoliang)

Fruit

Apple: Applejack Calvados Cashew Apple: Fenny Coconut: Arrack Grape: Armagnac Brandy Cognac Pisco Plum: Slivovitz uic Pomace: Grappa Marc Orujo Tsikoudia Tsipouro Zivania Chacha Various/other fruit: Eau de vie Kirschwasser Palinka Rakia Schnaps

Other

Agave: Mezcal Tequila Sugarcane/molasses: Aguardiente Cachaa Clairin Guaro Rum Seco Herrerano Tharra Various cereals and potato: Akvavit Baijiu Canadian whisky Poitin Shch Vodka Whisky

Liqueurs and infused distilled beverages by ingredients

Almond: Amaretto Crme de Noyaux Anise: Absinthe Arak Ouzo Raki Pastis Sambuca Chocolate Cinnamon: Tentura Coconut: Malibu Coffee: Kahlua Tia Maria Egg: Advocaat Hazelnut: Frangelico Herbs: Aquavit Bndictine Brennivn Crme de menthe Metaxa Honey: Brenjger Drambuie Krupnik Juniper: Gin Jenever Orange: Campari Curaao Triple sec Star anise: Sassolino Sugarcane/molasses: Charanda Various/other fruit: Crme de banane Crme de cassis Limoncello Schnapps Sloe gin

Alcoholic beverages category Pub Bar Tavern Drink Portal Beer Portal Beer WikiProject Wine Portal Wine WikiProject Spirits WikiProject

Categories: Cocktails with beer | Mixed drink shooters and drink shots | Naming controversies

I am an expert from cnc-machiningparts.com, while we provides the quality product, such as CNC China Machining Parts , China PEM Fastener, China machining parts China supplier,and more.

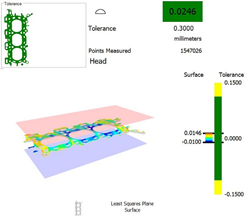

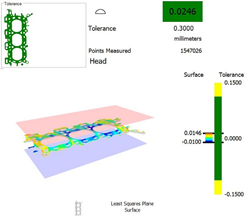

Ann Arbor, Michigan (PRWEB) August 19, 2014

Coherix, a leader in designing and delivering high-speed, high-definition, 3D metrology, and inspection capabilities for China manufacturing, and Concept China Machine Tool, a full service machine tool & metrology equipment dealer, have partnered together to bring the best available 3D micron level technology for multi-surface analysis to the Wisconsin area with a roadshow on August 28, 2014.

Coherix 3D technology provides a rapid, intuitive, and advanced multi-surface analysis of a part in a single view, allowing a user to make quick proactive decisions to adjust and refine a process. The user gains process knowledge for control and improvements through rapid feedback.

The 3D technology enables process improvement iterations to occur in minutes, not hours, and displays to the user results for adjusting a process successfully. The user is able to expedite the resolution of a problem within a process. This is done by comparing clear pictures of what is currently being produced, from what has proven functional before. As operators and quality control personnel gain confidence in the process, they can work on value optimization and produce the best part quality possible. This leads to lower costs in China manufacturing, less scrap, higher quality products, higher throughput, and increased customer satisfaction.

Coherix designs and delivers high-speed, high-definition, 3D metrology, and inspection tools for product development and the management of China manufacturing processes for the precision China manufacturing and semiconductor industries. Headquartered in Ann Arbor, Michigan, the company has technical centers in Europe and the Asia Pacific region. Coherix products are being utilized around the world at companies such as ASE, SPIL, Marvell, BorgWarner, Ford, Honda, Allison Transmission, Chrysler, General Motors, Micron, Infineon, John Deere, Volvo Technology Transfer, and Aisin among others.

Concept China Machine Tool (CMT) is a full service machine tool & metrology equipment dealer with its headquarters located in Minnesota and a branch office in Wisconsin. Concept China Machine Tool exclusively represents a variety of the world’s finest machine tools & metrology equipment manufacturers, and has kept abreast of technological change by representing the most sophisticated and advanced machines available today.

To schedule a visit, please contact Norma Regan, P: 734-922-4102, C: 734-276-2649.

precision China engineering components eBay auctions you should keep an eye on:

[wprebay kw=”precision+engineering+components” num=”2″ ebcat=”-1″]

[wprebay kw=”precision+engineering+components” num=”3″ ebcat=”-1″]

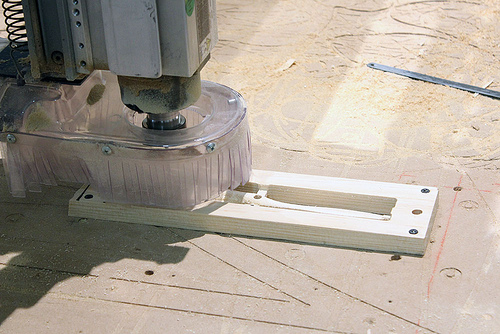

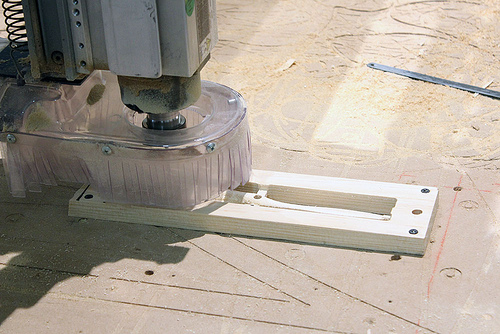

A few nice 3d milling images I found:

3D China Milling with a CNC Router

Image by AS220

Jens Dyvik taught members of AS220 Labs how to use the CNC Router to do 3D China Milling.

3D China Milling with a CNC Router

Image by AS220

Jens Dyvik taught members of AS220 Labs how to use the CNC Router to do 3D China Milling.

Some cool precision screw China machining images:

Screw Driver Bits – Assorted

Image by tudedude

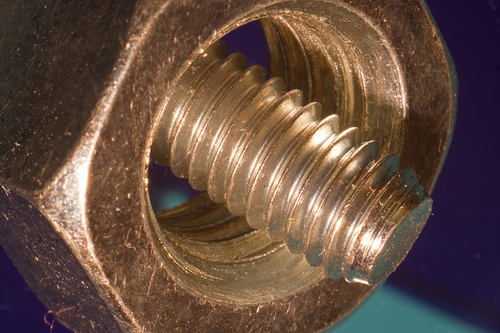

Nut and Bolt Mismatch

Image by tudedude

View On Black

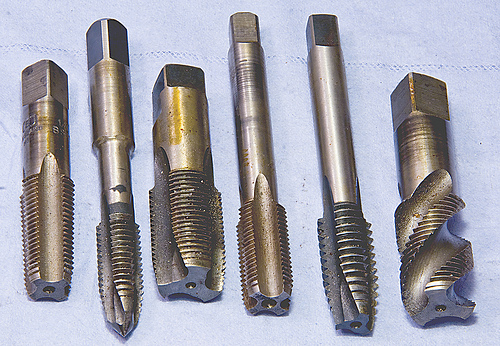

Assorted China Machine Taps

Image by tudedude

German Money China Machine – CNC China Lathe China Machine Working Video – Numerical control (NC) is the automation of machine tools that are operated by precisely programmed …

Turning on the lathe, CNC milling machine.

[youtube http://www.youtube.com/watch?v=TlMCat0O16o&fs=1&rel=0]

Crescent Industries manufactures precision Swiss screw machined components China. We offer these services for either finished product or as inserts for the insert …

Some cool precision machining in china images:

Steven F. Udvar-Hazy Center: Vought F4U-1D Corsair, with P-40 Warhawk and SR-71 Blackbird in background

Image by Chris Devers

Quoting Smithsonian National Air and Space Museum | Curtiss P-40E Warhawk (Kittyhawk IA):

Whether known as the Warhawk, Tomahawk, or Kittyhawk, the Curtiss P-40 proved to be a successful, versatile fighter during the first half of World War II. The shark-mouthed Tomahawks that Gen. Claire Chennault’s "Flying Tigers" flew in China against the Japanese remain among the most popular airplanes of the war. P-40E pilot Lt. Boyd D. Wagner became the first American ace of World War II when he shot down six Japanese aircraft in the Philippines in mid-December 1941.

Curtiss-Wright built this airplane as Model 87-A3 and delivered it to Canada as a Kittyhawk I in 1941. It served until 1946 in No. 111 Squadron, Royal Canadian Air Force. U.S. Air Force personnel at Andrews Air Force Base restored it in 1975 to represent an aircraft of the 75th Fighter Squadron, 23rd Fighter Group, 14th Air Force.

Donated by the Exchange Club in Memory of Kellis Forbes.

Manufacturer:

Curtiss Aircraft Company

Date:

1939

Country of Origin:

United States of America

Dimensions:

Overall: 330 x 970cm, 2686kg, 1140cm (10ft 9 15/16in. x 31ft 9 7/8in., 5921.6lb., 37ft 4 13/16in.)

Materials:

All-metal, semi-monocoque

Physical Description:

Single engine, single seat, fighter aircraft.

• • • • •

Quoting Smithsonian National Air and Space Museum | Lockheed SR-71 Blackbird:

No reconnaissance aircraft in history has operated globally in more hostile airspace or with such complete impunity than the SR-71, the world’s fastest jet-propelled aircraft. The Blackbird’s performance and operational achievements placed it at the pinnacle of aviation technology developments during the Cold War.

This Blackbird accrued about 2,800 hours of flight time during 24 years of active service with the U.S. Air Force. On its last flight, March 6, 1990, Lt. Col. Ed Yielding and Lt. Col. Joseph Vida set a speed record by flying from Los Angeles to Washington, D.C., in 1 hour, 4 minutes, and 20 seconds, averaging 3,418 kilometers (2,124 miles) per hour. At the flight’s conclusion, they landed at Washington-Dulles International Airport and turned the airplane over to the Smithsonian.

Transferred from the United States Air Force.

Manufacturer:

Lockheed Aircraft Corporation

Designer:

Clarence L. "Kelly" Johnson

Date:

1964

Country of Origin:

United States of America

Dimensions:

Overall: 18ft 5 15/16in. x 55ft 7in. x 107ft 5in., 169998.5lb. (5.638m x 16.942m x 32.741m, 77110.8kg)

Other: 18ft 5 15/16in. x 107ft 5in. x 55ft 7in. (5.638m x 32.741m x 16.942m)

Materials:

Titanium

Physical Description:

Twin-engine, two-seat, supersonic strategic reconnaissance aircraft; airframe constructed largley of titanium and its alloys; vertical tail fins are constructed of a composite (laminated plastic-type material) to reduce radar cross-section; Pratt and Whitney J58 (JT11D-20B) turbojet engines feature large inlet shock cones.

• • • • •

Quoting Smithsonian National Air and Space Museum | Vought F4U-1D Corsair :

By V-J Day, September 2, 1945, Corsair pilots had amassed an 11:1 kill ratio against enemy aircraft. The aircraft’s distinctive inverted gull-wing design allowed ground clearance for the huge, three-bladed Hamilton Standard Hydromatic propeller, which spanned more than 4 meters (13 feet). The Pratt and Whitney R-2800 radial engine and Hydromatic propeller was the largest and one of the most powerful engine-propeller combinations ever flown on a fighter aircraft.

Charles Lindbergh flew bombing missions in a Corsair with Marine Air Group 31 against Japanese strongholds in the Pacific in 1944. This airplane is painted in the colors and markings of the Corsair Sun Setter, a Marine close-support fighter assigned to the USS Essex in July 1944.

Transferred from the United States Navy.

Manufacturer:

Vought Aircraft Company

Date:

1940

Country of Origin:

United States of America

Dimensions:

Overall: 460 x 1020cm, 4037kg, 1250cm (15ft 1 1/8in. x 33ft 5 9/16in., 8900lb., 41ft 1/8in.)

Materials:

All metal with fabric-covered wings behind the main spar.

Physical Description:

R-2800 radial air-cooled engine with 1,850 horsepower, turned a three-blade Hamilton Standard Hydromatic propeller with solid aluminum blades spanning 13 feet 1 inch; wing bent gull-shaped on both sides of the fuselage.