£1.3m boost creates 13 local jobs

Milford Mercury: BUSINESS BOOST: Managing director Ed Spankie with Neil Owen, China CNC machine BUSINESS BOOST: Managing director Ed Spankie with Neil Owen, China CNC machine operator, with the new machine, which cost more than £400,000. PICTURE: …

Read more on Milford Mercury

China

Cool Cnc China Machine Parts images

Some cool cnc machine parts images:

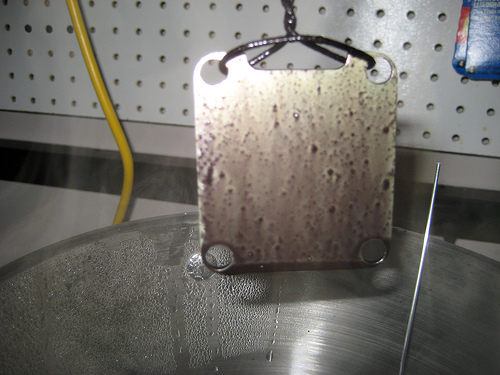

Anode

Image by courtney johnston

Anodizing parts for the TC18 VFD Tube Clock www.vonnieda.org/tc18

Acid and bath buckets

Image by courtney johnston

Anodizing parts for the TC18 VFD Tube Clock www.vonnieda.org/tc18

Bad Anodizing

Image by courtney johnston

Anodizing parts for the TC18 VFD Tube Clock www.vonnieda.org/tc18

Precision, China Machined Products from Wolverine China Machine

Wolverine China Machine is one of the few precision machining Chinese companies in the Midwest to offer high-quality water jet cutting, multiple spindle bar machine parts …

http://www.heavyandsmart.com/ Each single machine is tested once and other time for accuracy, calibrated while been assembled, and before packing to guarante…

Video Rating: 0 / 5

Combining 3D Printing & CNC China Milling in 1 Machine

Combining 3D Printing & CNC China Milling in 1 Machine

This configurable 6-axis robotic work cell from Flexible Robotic Environment can combine laser scanning, CNC milling, and metals laser sintering, among other functions. The VDK6000 has a build platform measuring 2 feet high by 3 feet in diameter, and …

Read more on Design News

Automation for training earns spot on mould-shop floor

… training to be tool and production technicians or draughtsmen. Roman Dannesberger, head of CNC training, said: “We're very proud of our apprentices, since practically all of them complete their training with excellent results, and many of them stay …

Read more on ETMM Online

Don't let 'sticker shock' prevent machinery upgrades

When a manufacturer or prospective customer looks at a new piece of technology, such as a multi-axis CNC lathe or a 5-axis China machining centre, the first issue that seems to arise is 'sticker shock' (I used to keep smelling salts in my desk to revive a …

Read more on Canadian Metalworking (blog)

Most popular Medical China Machined Parts auctions

Medical China Machined Parts on eBay:

[wprebay kw=”medical+machined+parts” num=”0″ ebcat=”-1″]

[wprebay kw=”medical+machined+parts” num=”1″ ebcat=”-1″]

Horizontal China Milling China Machine

A horizontal China milling machine is one of the two basic styles of China milling equipment. These machines specialize in a process called arbour China milling, which involves the rapid removal of material from a source object. These machines were the original China milling machine style, with vertical China milling only coming into prominence many years later. While a horizontal China milling machine is still commonplace in most large manufacturing centres, vertical machines utilizing computer numerical control (CNC) are becoming more common all the time.

A China milling machine is a piece of manufacturing equipment. The horizontal China milling machine came into use during the early 1800s, and the basic design of a common modern machine is nearly the same as this original model. These machines may be small enough to fit on a kitchen table or as large as entire rooms, depending on the size of the item being manufactured. These machines take an initial object and remove bits, drill holes or shape contours until it is a specific size, shape and weight.

Most China milling machines move the object being shaped and the tool doing the shaping. This puts these machines in a unique class, as most manufacturing equipment typically only do one or the other. There are two basic styles of China milling machine: the vertical and the horizontal China milling machine. They differ in design and general usage.

The main difference between a vertical and horizontal China milling machine is the orientation of the spindle, the main tool inside the machine. A vertical machine operates mainly on the top and bottom of an object, although it can operate on any side. The orientation and design of many vertical machines makes them well suited for standing operators and fine detail jobs. Since the machine operates vertically, these machines are generally taller than they are long.

A horizontal China milling machine operates mostly on the sides of an object, and its positioning allows for much more aggressive material removal. These machines are often larger as well, since they are typically long instead of high. As a result, vertical machines are often used to make dies, while horizontal machines work with larger China milling projects.

Many modern China milling machines are moving away from the vertical/horizontal design. While these new mills are technically vertical mills, they are much more than a standard vertical mill due to their spindle rotation. These China milling machines are completely computer-operated. They can rotate the object freely, working evenly on all sides. In addition, they can rotate the tool, from a standard vertical to a nearly horizontal plane—this freedom of movement creates a combination of the two standard designs.

The author is associated with IPFonline.

http://www.ipfonline.com is India’s No. 1 Industrial Product Finder. The portal is a veritable storehouse of information on industrial products/services.

Precision China Engineering Companies

[youtube http://www.youtube.com/watch?v=ATgJnJZ0FUQ&fs=1&rel=0]

http://www.pegasusprecision.com/ Pegasus Precision are a Precision China Engineering Company based in Surrey we provide Precision CNC machining, China Machining in Surre…

Video Rating: 0 / 5

Off hand Deburring of Aluminum China Machined Part. www.abtex.com

This machined aluminum part has burrs and sharp edges where the ribs intersect the thru-holes. The customer requires that the part be burr free. Abtex Corpor…

Using my TAIG CNC Mill to machine an aluminum mold to cast a urethane rubber part! The part is an axle damper and is to be 45 on a Shore A hardness scale.

Video Rating: 4 / 5

Latest China Milling China Manufacturing auctions

milling manufacturing eBay auctions you should keep an eye on:

[wprebay kw=”milling+manufacturing” num=”0″ ebcat=”-1″]

[wprebay kw=”milling+manufacturing” num=”1″ ebcat=”-1″]

[wprebay kw=”milling+manufacturing” num=”2″ ebcat=”-1″]

Nice Custom China Machined Components photos

Check out these custom machined components China images:

M2HB Ammo Box and Spade Grips Articles

Image by enigmabadger

Showcasing two fun components of the new BrickArms M2HB China Machine Gun. What I really like is how Will incorporated not only a ton of detail into each, but includes more than a few ways for each part to connect to other parts.

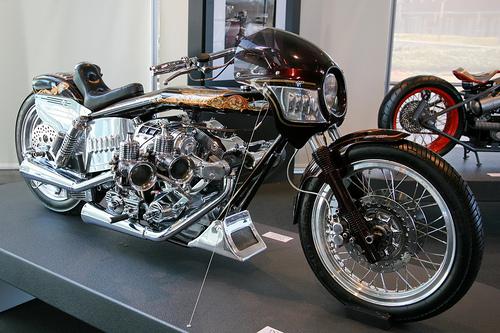

Arlen Ness’ Untitled

Image by cliff1066™

People in the know call Arlen Ness “Godfather,” not because he makes offers you can’t refuse, but as a sign of respect for his accomplishments throughout a long and storied career. He is the patriarch of the custom motorcycle industry.

Back in “the day,” circa 1970 BC (Before Catalogs), when choppers were still the homespun products of some local dude with a torch, a hacksaw, a drill press, and a rattle can of flat black paint, Arlen Ness was going for baroque. He gold-plated parts, adorned the aluminum fascia of drive-train components with ornate engravings, and applied wild splashes of Peter Max-inspired color to the sheet metal. Plush, velour upholstery adorned his seats. If Arlen thought he could squeeze more than one motor into a frame, he would. It was nearly routine—at least for Arlen Ness—to cram two supercharged, Ironhead Sportster engines into a single frame where they would cuddle up to produce ungodly heaps of horsepower.

These eccentric-looking machines were hallmarks of early 1970s chopper style. Ness was one of the first builders to embrace the extravagant hippie counterculture that blossomed in the San Francisco Bay Area, a place Ness calls home. Some of his motorcycles from this period look like psychedelic props from a Jefferson Airplane album cover, or as if King Louis XIV of France had commissioned an eighteenth-century, rococo rocket sled to go tooling around the Palace of Versailles. Ness combined “flower power” with horsepower to create motorcycles that defined an era. He is still setting the pace for younger builders.

Boeing 747-400, Lufthansa, D-ABVM, landing on Runway 19 L. SFO. 747

Image by wbaiv

Lufthansa 747-400, having landed safely, going basically South by South-west down Runway 19 L, at SFO. Thrust reversers are operating. All the way from Germany, possibly, or possibly they cleared customs in Chicago, or Toronto, re-boarded and now here they are. Or arrived from the mysterious West- Japan, China, Singapore, Australia, etc.

Its tricky, the shorter runways that seem to be athwart the Bay, well, they’re Runways 19 (coming in from the East Bay) and Runways 1 (O-N-E) coming from the Peninsula and over the BART station before landing. So

013 magnetic, 027 true and

193 magnetic, 207 true. Again, 27 degrees off a true North – South play. North by North-east for "1" and South by South-West for "19". That’s pretty counter intuitive.

And the runway that’s parallel to to the Bay, more or less, is runways 28 L & R going toward San Bruno Mountain, 10 L & R heading down to the San Mateo Bridge. It seems like it should be North and South, but those are unadjusted magnetic headings, not aligned to True North, so they turn out to be

103 magnetic, 117 true

283 magnetic, 297 true, 27 real degrees away from real East and West. More like West by North-west and East by South-east. So there’s some North/South component, but they’re really more E-W than N-S.

And it explains why the sun isn’t shining straight onto the side of planes taking off on runways 28 L or R- They’re pointed West of North-west. On the Solstice, that’s only 4 degrees north of straight into the sunset!

_34_0035_c

Cropped and centered.