Vasteras, Sweden (PRWEB) September 09, 2014

As the schedule ramps up to production of the COMAC 919, two very first-tier Chinese suppliers have bought fluid cell presses from Avure Technologies to decrease fabrication steps and drastically decrease the price of components they are manufacturing for the new single-aisle aircraft.

Shanghai Aircraft Manufacturing Co. Ltd. and Xizi Aviation will set up the sheet metal forming presses in facilities at Shanghai and Zehjiang, China, respectively.

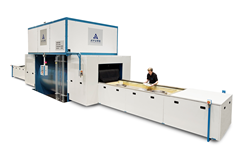

Shanghai Aircraft has chosen an advanced 68,000-ton fluid cell press, with a forming location of 1.4 x 4 m (55.1 x 157.5 inch), to extend its current capacity. Making use of ultra-high stress to type a wide range of complicated shapes, Avure Flexform™ fluid cell presses are a expense-effective, versatile manufacturing remedy, specifically when speed is vital in reducing time-to-industry and maintaining global competitiveness. The new Avure program is being designed for 1000 bar stress, a great asset when streamlining production to decrease the need to have for manual labor.

Xizi Aviation, a relative newcomer in the aerospace fabrication loved ones, chosen Avure’s recently introduced model, the QFC .7×1.8-800, a 17,000-ton fluid cell press with a table size of .7 x 1.8 m (27.6 x 72 inch) and designed for 800 bar pressure. With a rapidly, 60-second procedure cycle, combined with low operating fees, a space-saving little footprint, and straightforward installation directly at floor level, this press is a ideal match for Xizi’s concentrate on fabricating sheet metal parts for the airframe structure.

“These state-of-the-art higher-stress fluid cell presses are effectively suited to meet today’s imperative for much less and much less labor involvement, enabling the COMAC effort to compete with Western aircraft manufacturing approaches,” comments Sture Olsson, Avure’s Worldwide Metal Forming Enterprise Unit Director. “The introduction and mixture of higher-pressure, modern day tool design, and cautious fabrication logistics might decrease earlier essential fabrication steps by as a lot as 50 %, doubling the production capacity and cutting price by as much as 80 %.”

With 156 to 168 seats, the new C919 is a new short/medium variety commercial jetliner aimed at meeting increasing airline interest worldwide in single-aisle models. It is made to compete with the Airbus A320-NEO and the Boeing 737-MAX. All new aircraft styles seek to increase fuel efficiency, improve safety, enhance passenger comfort, and increase manufacturing efficiencies.

The new Flexform press will turn into Shanghai Aircraft’s second fluid cell press its first was supplied by Avure (formerly under the brand name ASEA, then ABB) nearly 30 years ago, and is nevertheless operational at complete processing parameters nowadays.

Avure will be exhibiting at EuroBLECH 2014 in Hannover, Germany, October 21-25, in Hall 17, Stand D122.

About Avure Technologies

An innovator with a powerful record of accomplishment, Avure Technologies (formerly recognized as ASEA, ABB, and Flow) demonstrates its knowledge in higher stress by occupying leadership positions in industrial and food applications. The business is the biggest worldwide provider of ultra-high pressure systems utilized to kind sheet metal, to process sophisticated materials, and to pasteurize foods without heat or chemical substances.

Avure has installed more than 1,700 high-pressure systems worldwide, more than all other competitors combined. These systems are characterized by technically sound design, superior reliability, energy efficiency, low maintenance expenses, and numerous years of encounter. Several Avure presses have been in service for more than 40 years, and some have surpassed 1 million higher-stress processing cycles.

Avure Industrial Group headquarters in Västerås, Sweden, home equipment style, manufacturing, and support operations, with additional facilities in Columbus, Ohio, USA, and regional sales and assistance operations globally. Read much more about Avure Technologies: http://sector.avure.com/goods/fluid-cell-presses-rectangular-forming-trays

About Shanghai Aircraft

Founded in 1950 and primarily based in Shanghai, China, Shanghai Aircraft Manufacturing Co., Ltd. manufactures and assembles aircraft components and elements, such as the horizontal stabilizers it produces for Boeing 737 aircraft. The business also supplies study and improvement and repair for massive industrial aircraft. It operates as a subsidiary of Commercial Aircraft Corporation of China, Ltd. Study a lot more about Shanghai Aircraft at http://english.comac.cc/

About Xizi Aviation

With its facility in Zhejiang, China, established in 2010, Xizi Aviation is a tier-1 supplier of the C919 aircraft airframe structure, also providing high-good quality merchandise and solutions for Airbus, Boeing, COMAC, AVIC, Cessna, Bombardier, and other individuals. Xizi Aviation capabilities extend from CNC machining, composite structures forming, and sheet metal forming, to heat and surface remedy, component assembly, digital measurement, and NDT. The business is a essential company sector of Xizi UHC, which contains three subsidiaries: Zhejiang Xizi Aviation Sector Co., Ltd., Shenyang Xizi Aviation Industry Co., Ltd., and Zhejiang Xizi Aerospace Fasteners Co., Ltd. Study more about Xizi Aviation at http://en.xiziac.com/