Milpitas, CA (PRWEB) May 20, 2015

Onanon, a leader in the extremely automated design and manufacture of customized electronic cables and connectors, announces the availability of its robotic automation Robo Hot Socket fast fine wire termination connector assembly technologies to all OEM application markets, efficiently supplanting the 40+ year old manual procedures nevertheless in use by most connector makers.

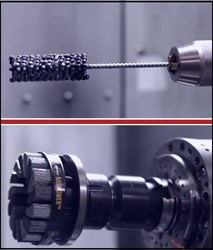

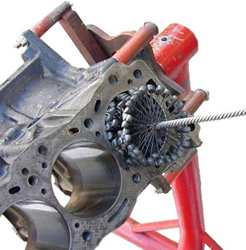

Onanon invented its Robo Hot Socket automated wire termination technology to take away human variables from the approach of the OEM cable to connector assembly. Onanon’s automated fine wire termination introduces greater sophistication chance into OEM connector design for manufacturing, improves high quality manage and substantially reduces assembly time. Onanon’s robotic automation of the complicated connector fine wire termination approach is field-confirmed in wire sizes from 22awg to 56awg.

A standard 34 pin connector requires 30 to 45 minutes to manually terminate its wires. This identical 34 pin connector is terminated in 4 minutes employing Onanon Robo Hot Socket robotic automation technologies with higher reliability, improved yields and enhanced good quality handle. By automating the fine wire termination procedure Onanon is capable to slash production cable assembly fees up to 50% and offer miniature assembly styles in no way just before manufacturing capable.

Manually terminating wires to solder cup pins is extremely labor intensive and creates troubles with top quality, price and delivery, along with extreme design limitations. Manual soldering to solder cup pins creates variables such as bridging, opens, incorrect wire location placements and operator security concerns (burning themselves while handling soldering irons so close to where they require to place the wire).

Printed circuit board connector substrates and versatile pads are manufactured with extremely loose tolerances. When adding the manual soldering variable to tiny PCB pads there are hi-pot, resistance, ionic contamination, cleaning challenges and style limitations. Rigid printed circuit board substrates and flexible pads are not sufficiently mechanically stable to reliably handle the axial load from a manually terminated fine wire.

Crimping for termination can be semi-automated but has a lot of style limitations and wire gauge size limitations. Miniaturization for complex connector style wire gauges are now as modest as 56awg. Therefore, conductor quantity is going up, and wire alloys are obtaining far more exotic as properly, rising manual connector manufacturing complications.

Connector OEM’s seek healthier margins via lowering charges. Raw components expenses becoming primarily the same the only sizable competitive benefits are to decrease assembly cost, minimize scrap and eradicate non-worth added processing.

Some connector OEM’s are turning to reduce labor nations such as China and India for their device manufacturing. This method introduces approach uncertainty, quality variables and, importantly, a loss of IP control.

“In today’s technological advancing connector business, adding more variables such as outdated manual assembly and unnecessary offshoring to a device, which includes disposable devices, is counter intuitive to the OEM’s bottom line,” says Dennis Johnson, CEO of Onanon. “Unnecessary manual processing introduces many non-worth added processes: extra inspections, extra testing, added handling, rework and RMA’s (Returned Supplies Authorizations).”

Onanon OEM Cable to Connector Automated Wire Termination Robo Hot Socket Summary of Functions:

Minimize production cost.

Lessen assembly time.

Increase yields and high quality manage.

Wire sizes from 22awg to 56awg.

Complex miniature style capable.

Get rid of unnecessary offshoring.

Keep IP handle.

Applications

Onanon cable to connector automated wire termination Robo Hot Socket technologies is applicable to fields such as automotive, avionics, military and healthcare devices.

Pricing and Availability

Onanon cable to connector automated wire termination Robo Hot Socket technology is available now, with JIT delivery. Contact Onanon for pricing data.

About Onanon

Onanon OEM cable assemblies and connectors are globally competitive and American created. Onanon engineers work closely with consumers to efficiently develop products that meets or exceeds their application requirements and are high top quality, expense powerful and designed for manufacturing. Onanon is ISO-13485 and ISO-9001:2008 certified, ITAR registered, RoHS 2 compliant, Reach compliant and Conflict Minerals compliant.

Onanon engineering supports a wide variety of customized, off the shelf needs, and modifies its production to meet specific medical, automotive, industrial, aviation, military and industrial applications. Onanon speedily and inexpensively takes cable assemblies and connector applications from design, prototyping and testing to production typically in a matter of weeks.

Speak to Onanon for consultation on Robo Hot Socket automated wire termination connector technology and applications. Telephone 1-408-262-8990. Fax 1-408-262-2901. E-mail: sales(at)onanon(dot)com. Internet site: http://www.onanon.com.

A lot more Rapid Prototyping Price Press Releases